Shijiazhuang Hanjiu Technology Co.,Ltd |

|

Verified Suppliers

|

|

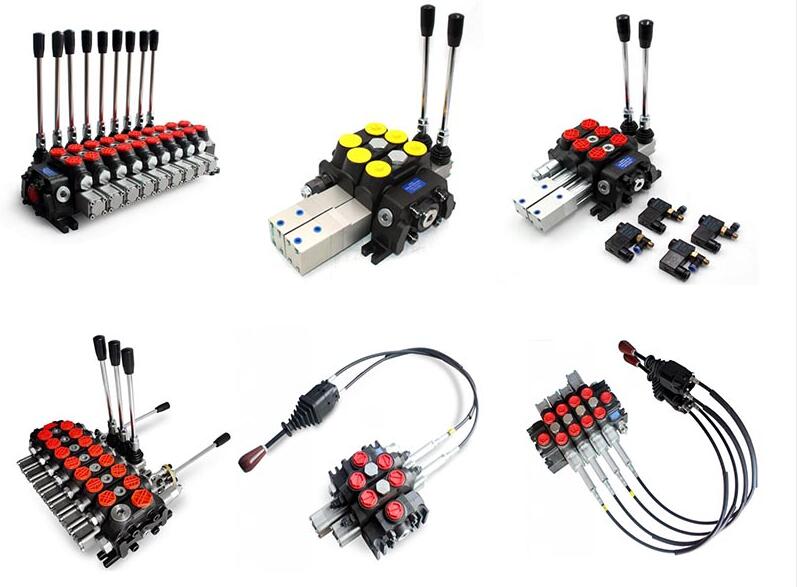

Mobile Directional Valves DCV200 Sectional 6 levers spring centered valves for construction and earth moving machines

DCV Series (DCV60 series & DCV100 & DCV140 Series & DCV200 Series)

| flow rate | 200liters/52.5GPM |

| number of spools | 6spools |

| inlet section valve | side inlet, with relief valve |

| relief valve set pressure | 100-315bar |

| inlet port size | G1 |

| spool type | 3 positon, double acting |

| handle side arrangement | standard handle |

| spool cap side arrangement | 3position, spring return,mantal control |

| working section arrangement | standard type |

| work port size | G3/4 |

| outlet section type | top outlet |

| outlet port size | G1 |

Directional valves are widely used in all walks of life, there are many advantages, but at the same time there are some limitations, understanding the disadvantages of directional valves can also be more convenient for people to choose.

1. Manual directional valve:

(1) It needs to be operated manually, which is relatively slow and cannot realize automatic control.

(2) Manual operation is prone to errors and requires relatively high operator skills.

(3) Compared with other types of valves, the manual fluid control ability of directional valves is relatively weak.

2. Solenoid directional valve:

The simple structure of the solenoid directional valve is its advantage, which is very easy to install, but this is also its limitation, because the valve core can only move between two extreme positions and cannot be adjusted continuously. Because the electromagnetic directional valve needs to interact with various forces during operation, the performance of the internal fluid medium will have a certain impact on these forces, which requires the medium to have good cleanliness and meet certain viscosity requirements. In order to ensure the reliability of the operation of solenoid directional valves, it is necessary to continuously improve the technology to overcome these innate defects.

3. Motorized directional valve:

The critical components of the motorized directional valve are susceptible to wear and tear, especially when used in large quantities, and need to be replaced or repaired regularly, and the maintenance cost is relatively high. In addition, the motorized directional valve needs to be cleaned regularly to ensure its proper functioning. The maintenance of motorized directional valves requires a relatively high level of technology and professional knowledge, and the operation is complex, which requires professional training by maintenance personnel, thereby increasing the maintenance cost. In addition, motorized directional valves and other equipment are mechanically bonded together, and multiple parts need to be separated and assembled during maintenance, which is a relatively difficult job.

4. Electro-hydraulic directional valve:

(1) There are many wearing parts. The internal structure of the electro-hydraulic directional valve is relatively complex, so there are many wearing parts. For example, the mechanical parts of the solenoids and switching spools tend to wear and tear out over time, which requires frequent replacement of parts, increasing maintenance costs and work.

(2) Frequent maintenance. Due to the large number of wearing parts, electrohydraulic directional valves also require frequent maintenance. If the damaged parts are not maintained and replaced in time, it will lead to the failure of the electro-hydraulic reversing valve, which will seriously affect the normal operation of the equipment.

(3) The performance stability is not high. The performance stability of the electro-hydraulic directional valve is not high, which is mainly because the response time of the electro-hydraulic directional valve is long during use, and it is easy to be affected by environmental factors such as temperature, humidity, and voltage. As a result, the valve cannot control the fluid on time, resulting in system instability.

(4) High energy consumption. Electrohydraulic directional valves usually require a high power supply to operate properly, so the energy consumption is also relatively high, which can cause certain economic pressure on the production enterprise.

4 way directional valve

directional control valves

SMC solenoid valve

solenoid directional valve