Wuxi Bird Machinery Technology Co., Ltd |

|

Product Description

Automatic CCD tea color sorter is a high-tech optoelectronic machinery and equipment, which is based on the color difference between tea stalk, yellow leaf and the accepted, using high resolution full-color CCD cameras to catch it.

Our tea color sorting machine can be used with black tea, green tea, white tea, dark tea, Tieguanyin, Pu'er tea and other varieties. It uses new anti-rust chutes, non-toxic,harmless, in line with international food safety standards. It uses tea professional channel, not blocking material, smooth and even, greatly reducing the rate of broken tea, double layer sorting can achieve sorting twice, reducing the feeding time and making color sorting performance more accurate, with a higher output. With full-color dual cameras, making it the best sorting equipment in the tea industry.

Technical Parameters

| Model | 6CSX-136S | 6CSX-256S | 6CSX-512S |

| Output(kg/h) | <100 | <200 | <400 |

| Carryover Rate(Bad:Good) | 10:1 | 6:1 | 6:1 |

| Sorting Accuracy(%) | ≥99.9 | ≥98 | ≥98 |

| Voltage (v/Hz) | 220V 50HZ | 220V 50HZ | 220V 50HZ |

| Power Supply(Kw) | 1.2-1.6 | 2.4-2.6 | 4.8-5.6 |

| Pressure(Mpa) | 0.5-0.7 | 0.5-0.7 | 0.6-0.8 |

| Air Consumption(L/min) | <1800 | <3600 | <5200 |

| Weight(Kg) | 400 | 720 | 1340 |

| Diamension(mm) | 1035*1934*2223 | 1073*1934*2223 | 2050*2050*2300 |

| Matching power / voltage | 0.8Kw/380v50Hz |

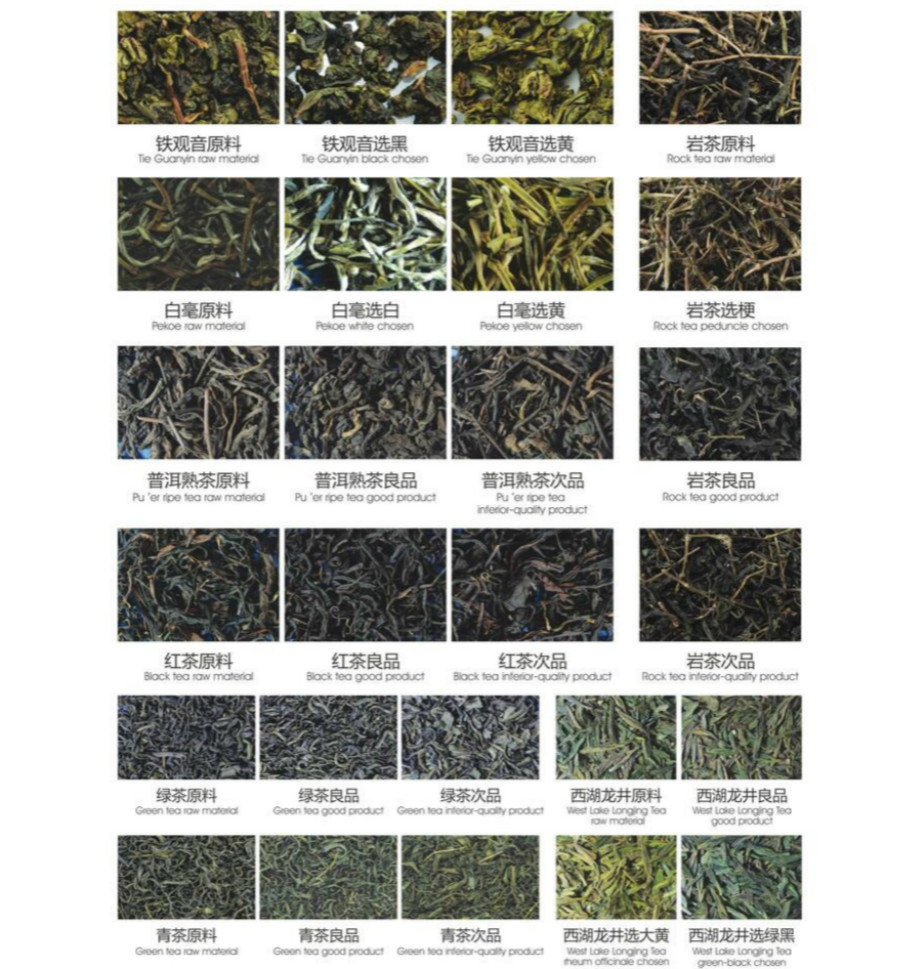

Examples of Sorting

Product Advantages

1. Linear array CCD full color sorting technology, high resolution

identification, high speed sorting and more precise identification.

2. Visible full-color spectral distribution, free to adjust the

spectral region.

3. Supports synchronized multi-tasking, various modes of color

sorting, supports sorting, resorting, a variety of colors

synchronized sorting, the yellow film in the tea, white, black,tea

stalk and other sorting at the same time.

4. Integrates shape difference technology, improving the accuracy

of tea leaves sorting quality.

5. Overcomes problems of current technology, such as Tieguanyin

sorting, etc. Achieving an intelligent and mechanized sorting.

6. Powerful intelligent software operating platform, easy to learn

and use, suitable for all levels of personnel operations.

7. Exclusive Color and Shape Sorting mode, to achieve a better

performance when differenciating the color of tea, twisted tea and

leaf foliage, improving sorting performance.

8. Mini Tea Color Sorter has small size, large output, about 100kg

per hour, suitable for home or small and medium-sized tea

processing plants.

Working Principle

Why Chose Our Tea Color Sorting Machine?

1.Over 14 years experiences.focus on sorter machine.The biggest sorter machine factory.

2.After-sales service guarantee: We have a professional after-sales service team, one-on-one customer service to help customers install and repair.

3.We have service station, cooperate reseller in more than 40 countries.

4.Quality assurance of raw materials:The raw materials we purchase are certified qualified products.

5.Quality process assurance: We pass ISO quality management system, each process of production are under strictly standard.

6.System test: Our technical engineers check the product performance, to ensure that the factory products in full compliance with customer requirements.

7.Shipping guarantee: we have professional packaging operations team, independent export qualification to ensure product safety and stability to reach customers in the hands.

Automatic CCD tea color sorter Problems Solutions

The equipment involves an automatic fault detection and alarm function, and the fault parts will be indicated by an indicator light or shown by a color display. Users can usually solve the problem by themselves.

| Faults | Causes | Solutions |

| Air leakage of solenoid valves | Foreign matters found in valves | Blow air into the valve in a reverse direction for repeatedly test |

| Wear of valve components | Replace worn parts | |

| Solenoid valves fail to work | Poor contact of valve wires | Re-plug or repair poor contact parts to enable good contact |

| Damaged control circuit boards | Replace control circuit control boards | |

| An inadequate amount of air injection for solenoid valves | Solenoid valves are not switched to the assigned location | Re-adjust or replace solenoid valves |

| Air pressure is too low | Check the pressure gauge and corresponding air piping

| |

| Rice leaps on rice channels | The water content in rice is excessively high | Dry the rice for re-sorting |

| Ashes on rice channels cake | Clean the rice channel with a piece of soft cloth | |

| Scratches occur on rice channels | Replace rice channels with new ones | |

| Frequent action of color sorting indicator lights and electromagnetic valves (fluorescent lamps) | Fluorescent lights are burn out | Replace fluorescent lamps with new ones |

| Color sorting modes are not set correctly | Set color sorting modes correctly | |

| Damaged power supplies for fluorescent lamps | Replace power supplies | |

| Background plates get stuck | Restore stuck boards | |

| Rice sorting waves are not correctly set | Re-adjust background plates | |

| Fluorescent lamps are not lightened | Re-lighten fluorescent lamps | |

| Circuit fault reminders appear | Circuit fault | Please contact us |

| Poor rice sorting results on channels at both sides | Fluorescent lamps are black at both ends | Replace fluorescent |

| The equipment don’t work at all | Sensitivity is too low | Adjust sensitivity |

| Background plates are improperly adjusted | Adjust background plates

| |

| Sorted grains are increasingly inferior ones during a certain period | Dust accumulates on glass plates in the sorting chamber | Wipe off dust with a clean piece of cloth |

| Parameters of sensitivity and background plates change | Re-set parameters | |

| Rice channels are unheated | Check the heating system | |

| Dust wipers are damaged and aged | Replace dust wipers | |

| Poor sorting results on a single side of the system | Poor cleaning results due to inappropriate action of rod less cylinders | Adjust the wiping speed of dust wipers |

| Color Sorters often shut down | Excessively high sensitivity; re-adjust the sensitivity | Background plates (or wave forms) are not adjusted properly |

| Re-adjust Background plates | Excessively high content of yellow grains | |

| Reduce output | Inadequate air supply pressure | |

| Check the air pressure and air passage to find out they are proper; re-adjust the air passage | Protection of air pressure often occurs | |

| Try to make pipes unblocked | clean or replace relative filter elements |