KYE Mould Techenology Limited |

|

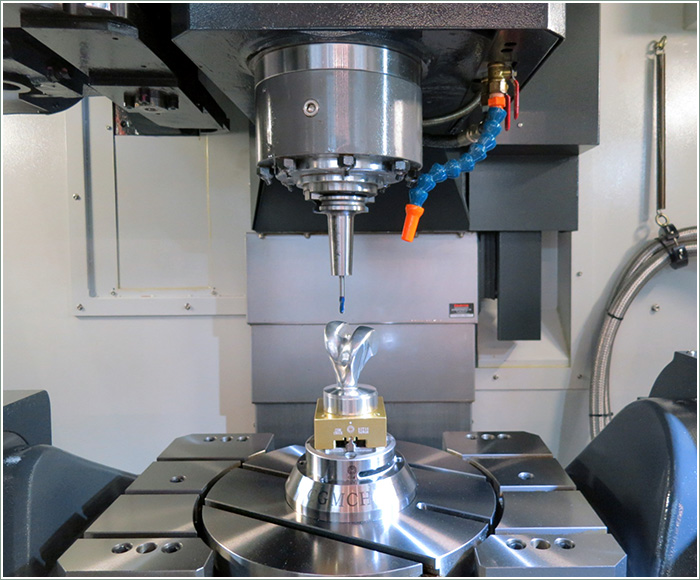

Polishing CNC IATF16949 Custom Component Machining

To be set up at 2009, KYE Mold is an advanced precision engineering

solution manufacture in Chang`an,Dongguan. Deploying advanced

production equipment and techniques, we provide innovative design

engineering solutions and manufacturing services to our customers.

We take a proactive role at the early stage of our customers’

product design and development cycles by providing value-adding

design engineering solutions and specific advice to them to resolve

particular design and technical issues, which differentiates

ourselves from traditional original equipment manufacturers and

original design manufacturers.

| Materials | Applicantion |

| iron | Steel, magnets, fuel, abrasive |

| aluminum | Smelting rare metals, manufacturing aircraft, rockets, automotive |

| structural materials,ultra high voltage cables, daily utensils, | |

| mechanical processing, electronic accessories, shipbuilding | |

| steel | Steel bridges, steel buildings, steel gates, large pipe containers |

| tall buildings, tower rail agencies, and construction installation | |

| copper | Electrical, electronics, motors, transformers, wire and cable |

| sliding bearing, mold, heat exchangers, pumps ,vacuum | |

| valves, fittings,instrument,distillation pot,pot Brewing | |

| shells, gun,pipeline, decorative devices,pot Brewing | |

| brass | Heat exchanger, condenser, low temperature pipeline |

| sea transportation pipe, sheet, strip, rods, tubes, | |

| casting parts, and the serpentine tube, cartridge | |

| aluminum alloy | Doors, windows, tubes, covers, shells |

| decorations, insulation, sheets, profiles, parts, | |

| brass alloy | Generator, bus, cable, switchgear, transformer |

| heat exchanger, pipeline, plate collector |

Our service

Customize all kinds of model Service-

Customize all kinds of model-field of application

Packing details

Our Advantage

Engineering solutions

We take a key role at the early stage of our customers’ product

design and development cycles by providing value-adding design

engineering solutions, including the choice of materials, the

production process flow and the application of production

techniques. This will provide them with more cost effective

solutions at the initial product design stage and enhance the

quality of their products.

Manufacturing services

They include the provision of a wide range of design and fabrication services of precision metal stamping tools, and manufacturing services of highly complex precision metal products involving metal stamping, cutting,machining, lathing ,sheet metal and turning procedures.

Assembly services

We also offer product assembly/integration services and logistics supports to our customers.

Why Choose Us?

1. 100% quality guarantee

2. 100% genuine material

3. Tolerance 0.005~0.1mm

4. One-stop service,from design to delievry

5. Small order accepted

6. Free sample or refund when order comfirmed

7. High speed machining will be shorter delivery and excellent

finish.

8. High quality, low prices,fast turnaround

9. Strict quality control system

10. Advanced equipment and excellent work team

Project process

Quote | According to sample, drawing and specific requirement. | |||

Discussion | Mold material, price, payment, etc. | |||

Advance | Payment by proforma invoice. | |||

Product Design Checking | We check the product design. If some position is not perfect, or

can not be done on the mould, we will send customer the report. | |||

Mold Tooling | We start to make mold after mold design confirmed. | |||

Mold Processing | Send report to customer once each week. | |||

Mold Testing | Send trial samples to customer for confirmation. | |||

Mold Modification | According to customer’s feedback. | |||

Delivery | Delivery by sea or air. The forwarder can be designated by your

side. | |||