Jiangyin Shunhao New Material Technology Co.,Ltd |

|

20g Water Electret Melt-Blown Non-Woven For FFP2, FFP3, KF94, KF99 Mask

Melt blown extrusion is a manufacturing process that is used for creating a type of fabric called non-woven fabric which is made from polymers such as polypropylene. ... The resulting fabric has a number of desirable properties that include: Absorbency. Bacterial barrier.

From the United States, it is different from the traditional melt-blown cloth electret process in that the traditional melt-blown cloth uses corona electret, whose surface electret is obvious, but the filtering effect cannot reach the peak value and storage will decrease with time, and the electrostatic attenuation on the material surface is obvious. The water electret melt-blown cloth is the pure water prepared by high pressure pump to the spunger device, and the fan-shaped nozzle spray the melt-blown cloth. The friction between the two produces static electricity. The performance of melt-blown cloth of water electret is static electricity saturation, and the charging method of water electret can be tested for overoil and salt, which can effectively solve the problem that the filter efficiency of melt-blown cloth electret decreases after storage in mask industry.

| Product Name | Water Electret Melt-blown Non-woven |

| Width | 1.6M |

| Weight | 20g |

| Filtartion Efficiency | ≥95% |

| Color | White |

| Application | Mask |

Process steps:

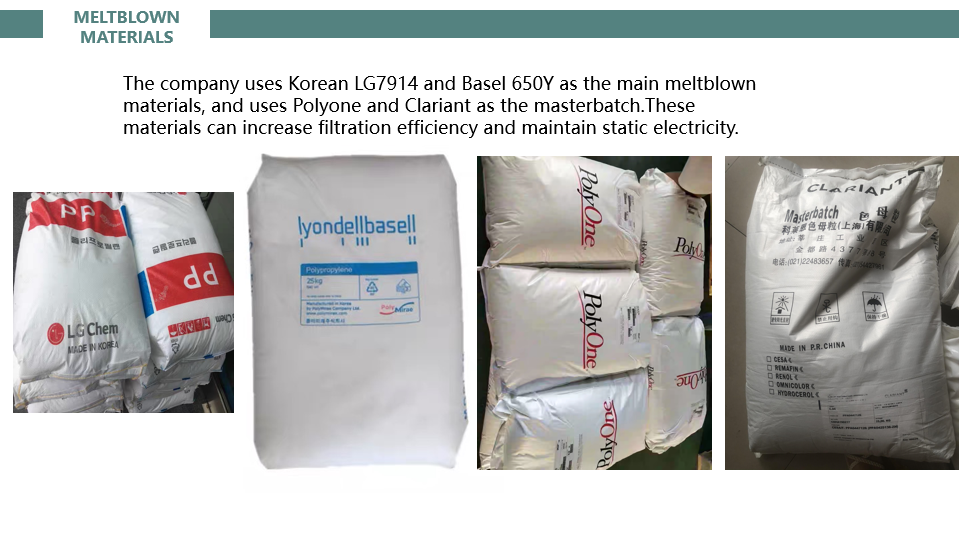

1. Melt-blown cloth generation: electret high fluidity

polypropylene, adding a small amount of water electret masterbatch

2. Pure water equipment: select tap water as the water source, the

water source for sand tank filtration and activated carbon

filtration, add reverse osmosis agent and hydrochloric acid to the

filtered water source, reverse osmosis membrane secondary

filtration of the water source, automatic detection to add alkaline

industrial reagents to the filtered water source, complete the

preparation of pure water.

3. Water polarizing process: the prepared pure water is transported

to the fan nozzle through the high pressure water pump, and the fan

nozzle spits the melt-blown cloth. The friction between water and

melt-blown fiber generates electric charge and completes the

spouting polarizing.

4. Drying process: the melt-blown cloth is sent into the drying box

through the transmission net, and the cloth is dried by hot air.

After drying, it is cut and wound.

At present, our company produces water electret meltblown nonwovens of 25g, 30g, 35g, 40g and so on, 95L air volume, oily filtration efficiency can reach 98-99%.