Chuzhou HH Non Woven Technology CO.,LTD |

|

Verified Suppliers

|

|

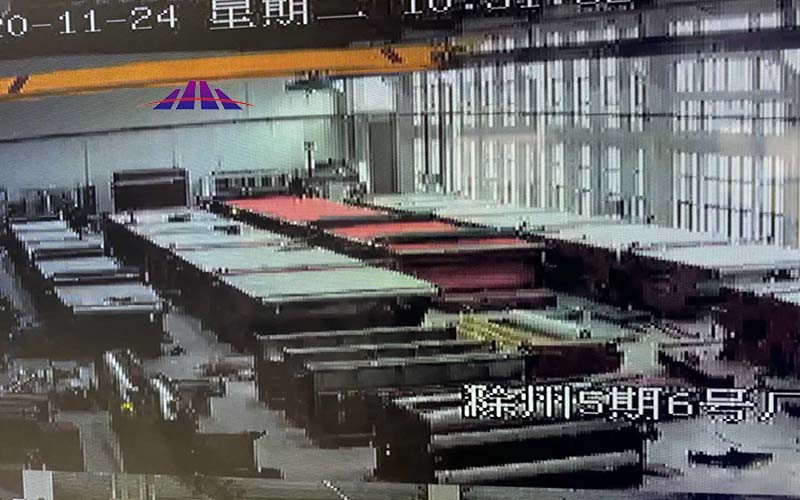

Medical non-woven Nonwoven Machine Roll SSMMS Composite Fabric Nonwoven Production Machine Meltblown Fabric Production

| HHM-SSMMS Five-Beam spunmelt nonwoven fabric making machine/line | |||||

Effective Width(mm) | Raw Materials | Max.Speed (Tons/year) | GSM Range (g/sq.m) | Daily Capacity (Tons/Day) | Annual Capacity (Tons/year) |

| 2400 |

Polypropylene(PP) | 600 | 9-80 | 23 | 8400 |

| 3200 | 31 | 11400 | |||

| 4800 | 40 | 14600 | |||

| The whole line can CUSOMIZED as your needs . | |||||

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web forming→Winding→Cutting→Final product

Key component

Maximum temperature

300 ℃

Max. Output

200 kg / h

Heating zone

8 tod

Perforated length

3,350 mm

HPI

40

Number of holes

5,276

1 Set L/D

10

Capillary diameter

0.3mm

Capillary length

3,600mm

Brand:HHM

Aperture (1pc)

90 300 kg / h

The screw L/D of the main extruder

30:1

The screw L/D of the ancillary extruder

15:1

Name:Filter

Brand:HHM

Original: China

Type: Hydraulic or Candle filter

Filter precision: 45μm~60μm

Fitration area: 2.5 m2for 1.6m,3.5 m2 for 3.2m

Heat source : heat-transfer oil , circular heating

Name: Spinning Box

Orifice number:11019 for 1.6m , 17651 for 3.2m

Orifice diameter:Φ0.45mm

L/D=4:1

Max temperature:300℃

Fuction : for spining the PP flament.

Draft divice , including up draft and down draft .spinning allows the thread to reach the right thickness through preciss drafting devices.

Advanced CNC center

Package and shipment

FAQ

A .Do you offer installing service?

Sure. We will despatch our technical workers to oversea sites to

instruct and help install the machines, meantime to train the

workers of customer until they can produce fabric by themselves.

B .What is your warranty?

We offer 1-2 years warranty upon the different parts.

C .How long is your delivery time?

Generally the production time needs 3-6 months upon condition. We will confirm you the exact time when you place order.

D .Are you factory or trading company? and where is your factory located, how can I visit it?

We are factory with export rights. We manufacture machines and export to customers by ourself. Our factory is located in Chuzhou City, Anhui Province, which is famous for making non-woven fabric machinery. You can take a plane to Nanjing / Shanghai Airport, or take a high-speed train to Chuzhou Station, we will pick you up.

E Why would i choose your product?

1.Quality Control in whole process, provide individual high

cost-effective nonwoven lines, helping customer cost saving.

2.Focus on non woven equipment research and development in 14

years. Install and running more than 200 lines all over the world

3.Over 20 person team for machine after sales service.Ensure the

customers can get quickly and professional installation and

debugged in time.