Chuzhou HH Non Woven Technology CO.,LTD |

|

Verified Suppliers

|

|

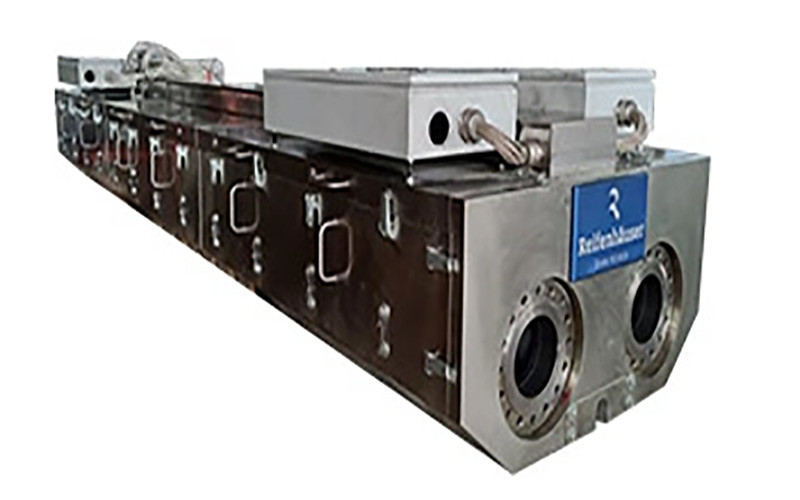

non woven fabric spinneret die spray Melt cloth mold plate spinnerets plate

Project configuration

| tem | Parameters |

| Spinneret hole diameter Micro hole distance | 0.3mm |

| Pitch | 0.7mm |

| Pitch | 1:10 |

| Width | 380mm (two cavity) |

| 400mm | |

| 600mm | |

| 800mm | |

| 1200mm | |

| 1600mm | |

| 2400mm | |

| 3200mm |

| Name | Spandex spinneret |

| Material | Forging Sus 630 sus431 |

| Specification | 1600-4000 mm |

| Hole type | Round |

| Diameter | 0.25-0.5 mm |

| L / D | 1:10 - 1: 15 |

spinneret dia and melt blwon dia for non woven making line as below

| Model | Effective width | Daily capacity | Speed | Spinning system | GSM Range | Machine dimension Length*Width*Height |

| HH-1600M | 1600MM | 2000Kg | 70M/Min | Meltblown | 15-300 | 18*10*10 meter |

| HH-2400M | 2400MM | 3000Kg | 18*11*10 meter | |||

| HH-3200M | 3200MM | 4500Kg | 18*13*10 meter | |||

| HH-1600S | 1600MM | 5000Kg | 150M/Min | Spunbond (S) | 9-250 | 18*8*12 meter |

| HH-2400S | 2400MM | 7000Kg | 18*10*12 meter | |||

| HH-3200S | 3200MM | 10000Kg | 18*15*12 meter | |||

| HH-1600SS | 1600MM | 9000Kg | 350M/Min | Spunbond (SS) | 8-150 | 45*15*12 meter |

| HH-2400SS | 2400MM | 13000Kg | 45*18*12 meter | |||

| HH-3200SS | 3200MM | 16000Kg | 45*20*12 meter | |||

| HH-1600SSS | 1600MM | 12000Kg | 550M/Min | Spunbond (SSS) | 9-120 | 50*15*12 meter |

| HH-2400SSS | 2400MM | 16000Kg | 50*18*12 meter | |||

| HH-3200SSS | 3200MM | 24000Kg | 50*20*12 meter | |||

| HH-1600SMS | 1600MM | 10000Kg | 350M/Min | Spunbond/ Meltblown/ Spunbond/ | 9-100 | 45*20*12 meter |

| HH-2400SMS | 2400MM | 14000Kg | 45*23*12 meter | |||

| HH-3200SMS | 3200MM | 18000Kg | 45*25*12 meter | |||

| HH-1600SMMS | 1600MM | 12000Kg | 450M/Min | Spunbond Meltblown Meltblown Spunbond | 9-100 | 55*20*12 meter |

| HH-2400SMMS | 2400MM | 17000Kg | 55*23*12 meter | |||

| HH-3200SMMS | 3200MM | 23000Kg | 55*25*12 meter |

1) Parts of spunbonded nonwoven fabric production line:

Recycle extruder---->Main extruder---->Filter---->Metering pump---->Monomer suction device--->Spinning box(ENKA/KASEN spinneret)---->

Quenching air chamber---->Stretching device---->Web former---->Calender---->Winder---->Slitter

2) Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)---->Raw material----> Melting---->Filtering---->Measuring ---->Spinning---->Cooling---->Stretching---->

Web forming---->Calendering---->Winding----> Cutting---->Final product

Precisely CNC center hold machinning parts beyond customer request

Exhibition with customer

Packing & logistics

Will packing and loading as you need .

Make sure all products are qualified

DHL UPS FEDEX TNT EMS etc

Pre-sales Services

1. Tell customer the features and application of the machine in details.

2. Help customer to select suitable, cost-effective and practical machine configurations, as per the material features and processing requirements.

3. Provide machine trial running for material testing.

Sales Service

1. Provide engineering conditions required by the project and design the layout of the installation of the whole machine line for customer according to customer's factory condition.

2. Update the production schedule with you in time.

3. Discuss with you about the process required for your materials, screw combination arrangement, barrels arrangement, etc. Finally we will provide you the related drawings of screw combination and barrels arrangements.

4. The machine will be made according to the technical docs confirmed by our both parties and shipped on time.

After-sales Service

1.Always provide on-line support and

video technical support.

2. Provide instructions about how to install and debug the machine. And also provide the training of the operation workers.

3. Establish detailed user service files and provide lifelong tracking service.

4. The whole machine is guaranteed for one year

5. Ensure sufficient supply of spare parts and provide free technical consulting services for a long time.