Suzhou Xunshi New Material Co., Ltd |

|

Verified Suppliers

|

|

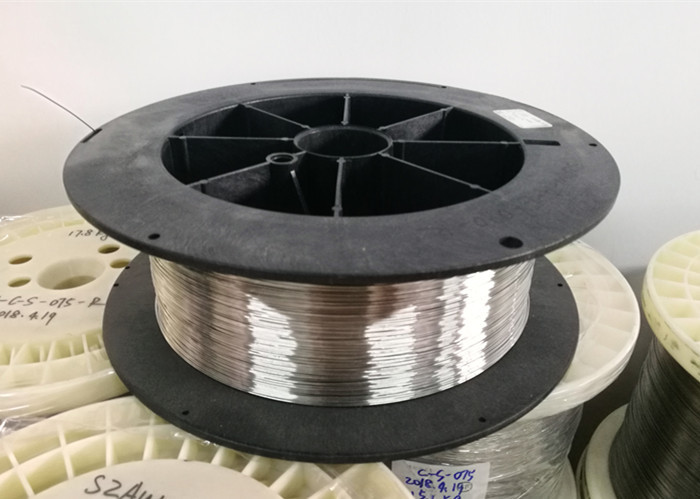

Magnetostrictive Waveguide Diameter 0.75mm For High Precision Liquid Level Sensor

XUNSHI is one of the most important magnetostrictive waveguide wire suppliers in China.

We have rich experience of supplying Magnetostrictive waveguide wire to customers from worldwide.

Our wire is widely used in Magnetostrictive level gauge/sensor/probe. We keep stock of 100,000+ meters of magnetostrictive alloy wire of diameter 0.50mm/0.75mm/0.80mm. This makes it possible for us to make the-next-day delivery.

Magnetostrictive waveguide wire

As a sensitive detection element, magnetostrictive waveguide wire

plays a decisive role in the magnetostrictive liquid level

meter/sensor. High-quality waveguide wire helps companies improve

the product performance of liquid level gauges and sensors, expand

product visibility and reputation.

Working principle of magnetostrictive level gauge and sensor

The detection mechanism of the magnetostrictive level gauge/sensor

is based on the Weidmann effect between the core detection element

of the sensor, the magnetostrictive waveguide wire and the vernier

magnetic ring.

During measurement, the excitation module in the electronic

compartment applies an interrogation pulse at both ends of the

sensitive detection element (magnetostrictive waveguide wire). This

pulse creates a circumferential ampere-shaped toroidal magnetic

field around the waveguide wire at the speed of light. When the Abe

ring magnetic field couples with the bias permanent magnetic field

of the vernier magnetic ring, a Weidmann effect torsional stress

wave will be formed on the surface of the waveguide wire. The

torsional wave propagates from the generating point to both ends of

the waveguide wire at the speed of sound. The torsional wave

transmitted to the end is absorbed by the damping device, and the

signal transmitted to the excitation end is received by the

detection device. The control module in the electronic warehouse

calculates the time difference between the query pulse and the

received signal, and then multiplies it by the propagation speed of

the torsional stress wave in the waveguide material (about 2830m/s)

to calculate the distance between the location of the torsional

wave and the measurement reference point. distance, that is, the

absolute distance between the vernier magnetic ring and the

measurement reference point at that instant, thereby achieving

real-time accurate measurement of the position of the vernier

magnetic ring.

what we can offer

As a professional magnetostrictive waveguide wire supplier, we can

provide products with complete specifications, competitive prices

and timely and thoughtful services.

We always have:

Common waveguide wire (-40~80°C) diameter 0.50mm, 0.75mm, 0.80mm,

1.00mm,

High temperature resistant waveguide wire (maximum operating

temperature 280°C) diameter 0.50mm, 0.80mm

Performance Testing

We have special testing equipment and will conduct signal detection

after each batch of waveguide wires is produced to ensure

consistent quality of waveguide wires.

Packaging and shipping

To ensure performance, the waveguide wire cannot be bent or

scratched. To ensure that the product is not damaged during

transportation and affects performance, we have specially

customized packaging to ensure that the quality of the product when

it is delivered to the customer is as good as when it leaves the

factory.

About XUNSHI

Suzhou Xunshi New Material Co. Ltd- referred as XUNSHI hereafter, is a professional manufacturer of high-performance alloy products. XUNSHI is engaged in supplying high quality and cost-effective Superalloy, Anti-Corrosion Alloy, Precision Alloy, Special Stainless Steel and Magnetostrictive Material to customers worldwide.

Why XUNSHI

· Highly experienced in alloy industry

· Top experts of industry in China

· Advanced technology and process from top famous institutes in China

· Advanced devices through whole production and inspection process

· Strict quality control system

· Company motto: best service, most value

· Smart sales policy

Service Items of XUNSHI

· Non-standard product research and pre-production

· Fabrication of products

· Cutting, splitting for sheets and plates in stock

· Heat treatment (Solution treatment, aging harden treatment, anneal, spring temper, quench etc.)

· Surface finish (peeling, gridding, polishing)

· Logistics service

· Customized packing service (also for exporting)

· Import and export (XUNSHI is certificated)

· Document translation

· Hard-to-find material sourcing

Customers of XUNSHI

Customers of XUNSHI are all over China (Taiwan and Hong Kong included). And we are exporting to USA, Canada, Italy, UK, Poland, Greece, Russia, Turkey, Iran, Israel, South Africa, South Korea, North Korea, India, Argentina, and Brazil and so on. Customers from 30+ countries trust us.

Where is XUNSHI

A- XUNSHI is in Huaqiao, Kunshan, 215332 China, which is very closed to Shanghai.

B- Xunshi is around 80KM from Shanghai Pudong International Airport (PVG).

C- 20KM from Shanghai Hongqiao Airport

D- 20KM from Shanghai Hongqiao Railway Station

E- You can contact XUNSHI sales for a pickup service.