Guangdong Kenwei Intellectualized Machinery Co., Ltd. |

|

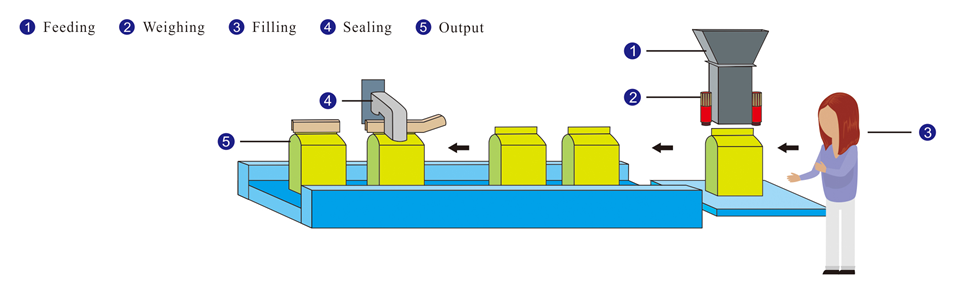

Semi-Automatic Linear Weigher Packaging Machine With Vacuum Feeding Machine

The system including vacuum feeder,4 head linear weigher, working platform, sealer. Semi-Automatic Linear Weigher Packaging Machine With Vacuum Feeding Machine is equipped with a vacuum feeding machine and a 4-head linear scale, which mainly weighs milk powder, coffee, seasoning powder, and other materials. With a 4-head linear scale, up to 4 materials can be weighed separately. The feeder reduces the loss of materials during the weighing process and at the same time makes the accuracy more precise.

Suitable for white sugar, salt, seeds, rice, sesame seeds, MSG, chicken essence, milk powder, coffee, seasoning powder and other powdered, small grainy more uniform materials quantitative weighing.

1. Automatic completion of the feeding, weighing, and finished

product outputting of the process.

2. The scope of application is wide, the material adapts strongly,

the measurement accuracy is high, the measurement efficiency is

high.

3. The system is compact, high measurement accuracy, can

effectively save input costs, improve measurement production

efficiency.

4. Suitable for the liquidity of small particles, powder, powder

mix, and other materials for accurate weighing packaging.

5. With cheap, economical, cost-effective, space-saving, is the

packaging speed requirements are not high or packaging machine can

not pack the ideal customer.

Mechanical character

| 1.The system is simple and easy to operate with high cost performance. |

| 2.Suitable for weighing powder and granules, High weighing precision and efficiency. |

| 3.The max Packaging speed 40p/min (But need two person to collecting the product, the multihead weigher is in a normal load working state). |

Check weigher: Used for check weight, and remove the unqualified products, classification, and statistics of products. |

Horizontal metal detector: Used to detect both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detecting after packaging. |

Dropped metal detector: Used for detecting both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detecting before packaging, and fixed between the bottom of the weigher and the top of VFFS feeding funnel, save space, but increase the hight of system. |

Combined check weigher and a metal detector: Used to check the weight of products and detect the metal which mixed in the products, remove the unqualified products. It Combines check weigher and metal detector, save cost, and the time of debugging and maintenance. |

Finished product conveyor: Used to convey the product to the next process. |

13 years of experience in product customization and practical industry application. Special program technical team with rapid response. Tailored products and solutions with high pertinence and applicability are delivered after the comprehensive planning and evaluation based on the customer’s actual production situation and usage.

Adopting well-known Japanese and German brand load cells. Key components such as hoppers, linear pans, waterproof cover are made by high-precision molds, which contributes to high consistency and interchange-ability. The circuit board design adopts the industrial-grade design scheme, the industrial-grade material, and the manufacturing technology from the chip selection to the PCB design and the protection. The standard touch screens use an LCD screen of 50,000-hours-life, which adopts the immunity standard higher than the EC general standard industrial environment, and achieves a high-level design of 4kV.