Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

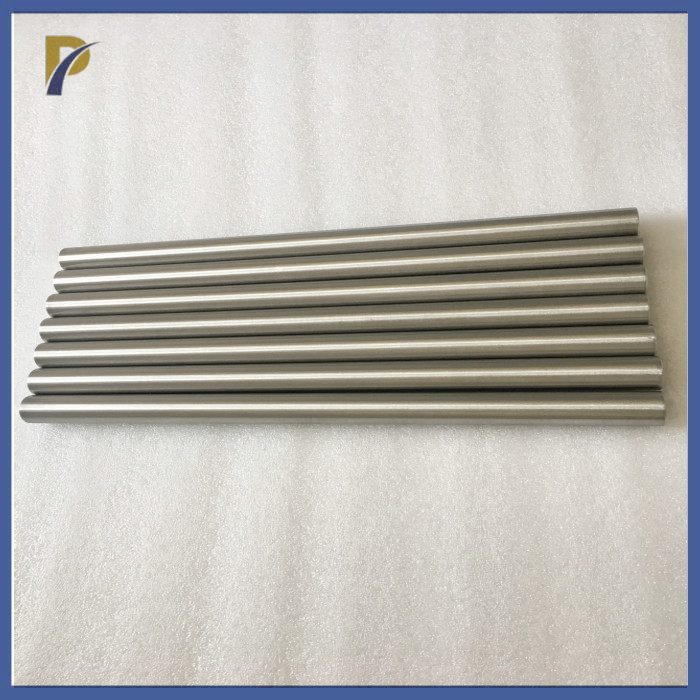

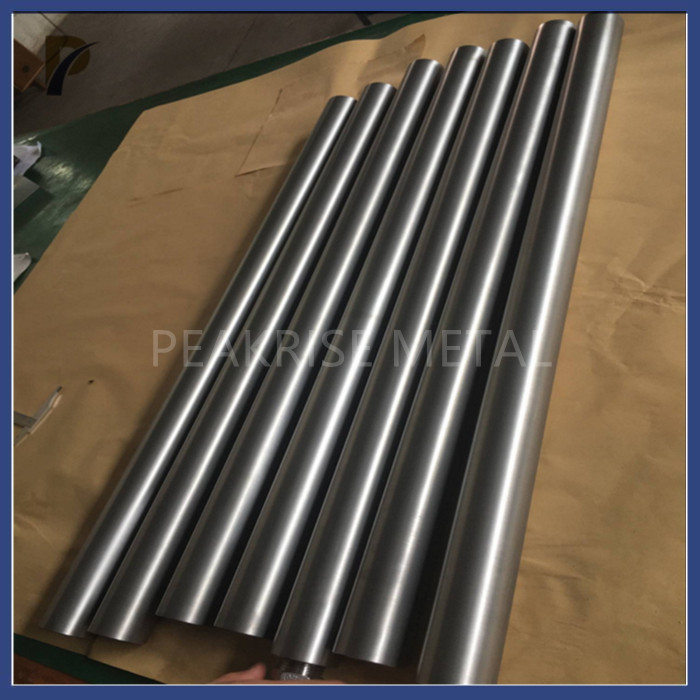

Molybdenum Lanthanum Alloy Bar

1. Description of Molybdenum Lanthanum Alloy Bar:

High-temperature molybdenum, grade MoLa, commonly known as molybdenum-lanthanum alloy, is made by doping molybdenum with a small proportion of lanthanum trioxide (La2O3) particles. This special microstructure remains stable at temperatures up to 2000°C. Consequently, even in operational settings, molybdenum-lanthanum oxide exhibits creep resistance. We mainly process these molybdenum alloys into high temperature furnace components such as vacuum furnace heat shields, heating body bars, sintering and annealing boats, stranded wires or evaporator coils.

2. Size and Tolerance of Molybdenum Lanthanum Alloy Bar:

| Name | Diameter | Tolerance of diameter |

| Forged MoLa rod | >80mm | +/-2.0mm |

| 25mm-80mm | +/-1.0mm | |

| swaging MoLa rod | 10mm-25mm | +/-0.2mm |

| 3.0mm-10mm | +/-0.1mm | |

| Bright MoLa rod | >20mm | +/-0.2mm |

| straighten MoLa rod | 0.5mm-3.0mm | +/-0.03mm |

| Polished MoLa rod | 0.8mm-50mm | +/-0.2mm |

3. Advantages of Molybdenum Lanthanum Alloy Bar:

1).The recrystallization temperature is higher 1400℃~1500℃;

2).Elongated particulate structure for improved ductility;

3).Antioxidant is stronger;

4).Higher creep resistance.

4. Resistivity of Molybdenum Lanthanum Alloy Bar:

| Temperture℃ | 20 | 600 | 1000 | 1200 | 1400 | 1700 | 1800 | 1900 | 2000 |

| Resistivity | 0.054 | 0.205 | 0.314 | 0.374 | 0.435 | 0.506 | 0.525 | 0.558 | 0.571 |

5. Chemical content of Molybdenum Lanthanum Alloy Bar:

| Grade | Main element% | Impurity components(less than%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remian | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remian | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remian | — | — | — | 0.4~0.7 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

Do you want to know more about our products?