Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

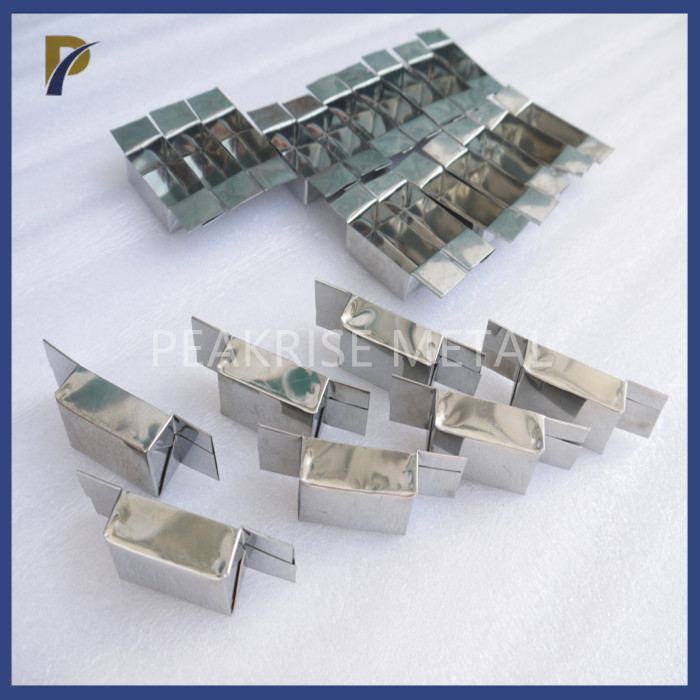

99.95% Foldable Tungsten Boat For Coating

1. Description of 99.95% Foldable Tungsten Boat For Coating:

The folding tungsten boat is made by repeatedly folding and forging the tungsten plate, and then folding the two ends of the tungsten plate for processing, and finally forming the shape of the boat. The permeability of the folded tungsten boat is strong. The folded ends are generally small rounded or branched. The difference from other types of tungsten boats is that this type of tungsten boat is generally composed of a tungsten boat cover and a tungsten boat body. The general tungsten boat cover is provided with an evaporation hole, the evaporation hole is a circular hole, the diameter of the circular hole is 1mm, and the hole spacing can be set to 2mm.

2. Size and Chemical of 99.95% Foldable Tungsten Boat For Coating:

| Quality Standard (99.95% W) | |||

| Element | Value (<ppm) | Element | Value (<ppm) |

| Fe | 5 | Mo | 10 |

| Ni | 3 | P | 1 |

| Al | 2 | C | 5 |

| Si | 3 | O | 5 |

| Ca | 3 | N | 3 |

| Mg | 2 | ||

The size according to customer's drawing.

3. Process craft of 99.95% Foldable Tungsten Boat For Coating:

When folding, the folded part should be in the same direction as the surrounding metal streamline. The starting position of the fold is related to the corner radius of the blank before forging. If the corner radius is too small, the formed fold may enter the inside of the tungsten boat, otherwise, it will not be able to fit the same fold. First, the tungsten plate is punched into a thin plate that meets the size and thickness, and then the thin plate is bent into a certain angle by heating at a high temperature. It is finally processed into the size required by the customer.

4. Advantage of 99.95% Foldable Tungsten Boat For Coating:

1). Foldable tungsten boats are reinforced because the two ends of the tungsten boat are folded for many times, which improves the quality of this type and has a more beautiful appearance.

2). The stable structure also makes it last longer. The tungsten

boat prepared by folding and forging has high hardness and

toughness, and the effect of repeated use is better.

3). Since the interface of the materials used in the coating

process is larger than 1mm, the evaporation holes on the tungsten

boat cover can effectively prevent the raw materials from splashing

out of the tungsten boat, saving raw materials.

5. Defect of 99.95% Foldable Tungsten Boat For Coating:

Folded tungsten boats are prone to cracking after quenching or become a source of fatigue during use.