Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

Molybdenum Electrode Bar For Fiberglass Furnace

1. Description of Molybdenum Electrode Bar For Fiberglass Furnace:

Molybdenum electrode bar has a high melting point, good thermal conductivity and low thermal expansion properties. At high temperatures, it is anti-oxidation and has high strength so in many areas are widely used. Its production processing steps are as follows: molding, sintering, drape forging and machining.

2. Physical property of Molybdenum Electrode Bar For Fiberglass Furnace:

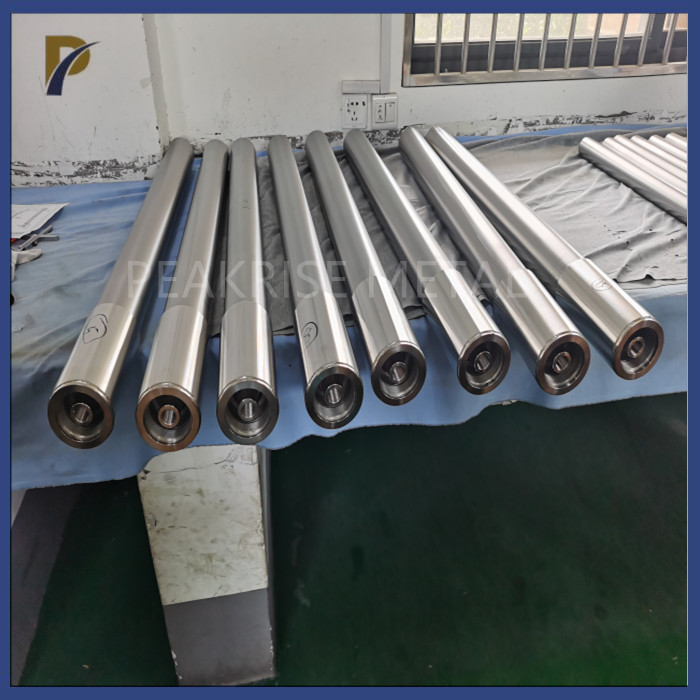

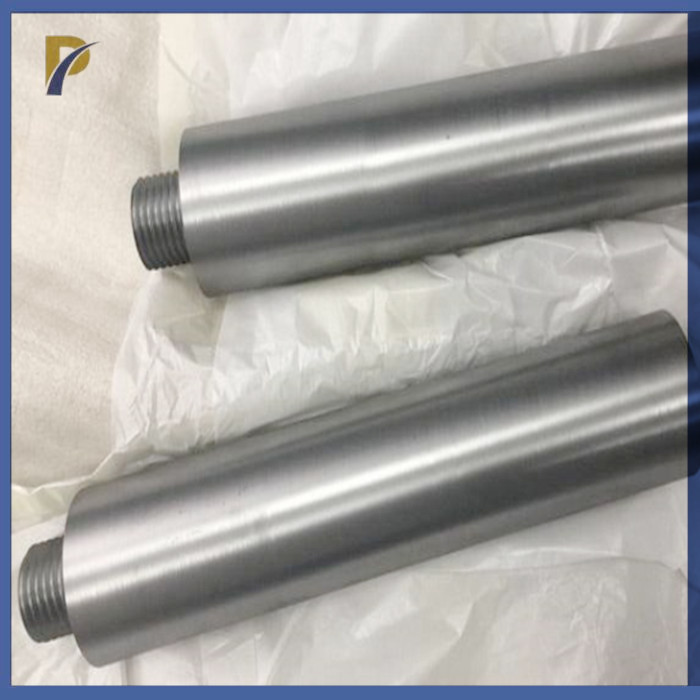

Molybdenum electrode bars appearance: silver gray metallic luster

and no off side angle, delamination, cracks or other defects,

according to user needs can be bent and straightened.

Density:≥9.8cm3

Purity: Mo≥99.953%

Specification: (14-20)×(14-20)×L≤1000mm

Uses: mainly used for electric melting furnaces or electric

boosting glass furnaces and glass furnace heating devices.

3. Classification of Molybdenum Electrode Bar For Fiberglass Furnace:

Molybdenum electrode bar can be divided according to material:

molybdenum electrode bar, high temperature electrode bar, forging

electrode bar, forging electrode bar and TZM electrode bar, their

content and appearance characteristics are as follows:

Molybdenum electrode bar: molybdenum content greater than 99.95%.

Remove the impurities from the high temperature electrode bar of lanthanum (contains 0.4–1.2% of it), and the remaining material is molybdenum.

TZM electrode bar: Mo-0.5, Ti-0.07~0.12, Zr-0.01~0.04

Sub-forging electrode bar: slight surface oxide film, hammer marks

polish electrode bar: surface showing metallic luster, no oxidation

4. Molybdenum electrode bar for fiberglass furnace surface oxide removal methods:

Molybdenum Electrode bar has a characteristic which is easily oxidized, if necessary to remove heavy oxides can take acid treatment, such as fluorine acid nitric acid or hydrochloric acid and other. But during the operation pay attention to safety and taking certain safety measures. Remove light oxides can add an abrasive cleaning agent and wipe with a soft cloth or sponge, and finally wash with warm water, but cleaned molybdenum electrode bar will lose metallic luster.

5. Application of Molybdenum Electrode Bar For Fiberglass Furnace: