Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

Application Of 99.97% High Purity Molybdenum Electrode In Opal Glass Furnace

1. Profile Of Molybdenum Electrode In Glass Furnace:

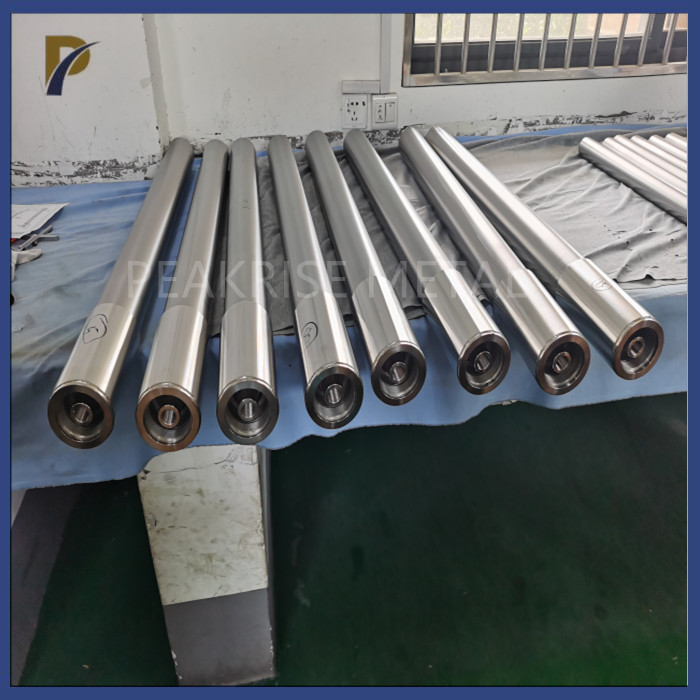

Molybdenum electrode for glass melting furnace is an electrode used in the glass industry and is widely used in the melting process of glass. Molybdenum electrode for glass melting furnace is usually made of high-purity molybdenum material, and its surface treatment adopts special technical process. The size and shape of molybdenum electrodes can be customized according to different furnace types and glass production process requirements. Molybdenum electrodes are mainly used in the melting process of electroslag melting glass and sodium glass, and have the advantages of high temperature corrosion resistance and long life.

2. The Size Of Molybdenum Electrode In Glass Furnace:

| Diameter | 10~100mm |

| Length | 150~3000mm |

| Purity | 99.97% |

| Density | 10.2g/cm3 |

| Straightness | Forging rod ≤1% Sintered rod ≤2% |

| Elongation | ≥10% |

| Melting Point | 2620℃ |

3. Tolerance Of Molybdenum Electrode In Glass Furnace:

| Diameter and Tolerance (mm) | ||

Forged or Sintered molybdenum rod | <10 | ±0.1 |

| 10~30 | ±0.1 | |

| 30~60 | ±0.1 | |

| 60~100 | ±0.2 | |

| 100~200 | ±0.2 | |

| >200 | custom as per customer request | |

4. The influence of the molybdenum electrode of the glass melting furnace on the glass solution mainly has the following aspects:

The influence of electrode material on glass composition: Molybdenum electrodes are easily oxidized at high temperature and release molybdenum oxide, which may affect the glass composition. Therefore, during the manufacture and use of molybdenum electrodes, special treatment of the electrodes is required to avoid negative effects on the glass composition.

Effect of electrode surface on glass quality: The surface treatment of molybdenum electrodes directly affects the contact quality between electrodes and glass, which may affect the quality of glass. Therefore, during the manufacture and use of molybdenum electrodes, special attention should be paid to the process and quality of surface treatment.

The influence of electrode material on glass production efficiency: molybdenum electrode has excellent high temperature corrosion resistance, making it one of the important materials in glass production. The use of molybdenum electrodes can increase the temperature of glass melting, speed up the melting speed and improve production efficiency.

Influence of electrode shape on glass flow: The shape of molybdenum electrode will also have certain influence on glass flow. Different shapes of electrodes will affect the flow speed and direction of glass. Therefore, in the furnace design and production process, it is necessary to choose the appropriate electrode shape according to different requirements and processes.

In general, molybdenum electrode, as an important electrode material for glass melting furnace, has an important influence on the composition, quality and production efficiency of glass. In the process of using molybdenum electrodes, it is necessary to pay attention to the material, surface treatment, shape and other aspects of the electrodes to ensure the quality and efficiency of glass production.

Why Choose Us:

Shaanxi Peakrise Metal Co.,Ltd is a manufacturer specializing in the production of molybdenum products. Our molybdenum electrodes are currently exported to Iran, India, Kuwait, Italy and other countries, and are well received by customers.

1. Our Puirty is more than 99.97%,high-purity molybdenum powder plays a key role in the coloring of glass because there are few impurities.

2. We will do 2~3 times flaw detection in the production process,guaranteed to deliver high quality products to customers. Many suppliers will say to do flaw detection, but few will actually do it.

3. Very fast delivery time, usually 10~15 work days. Individual large quantity orders will be extended.

4. Rich experience, we have more than 15 years of production experience and export experience in the field of tungsten and molybdenum products.

5. Good after-sales service.

Do you want to know more about our products?