Shaanxi Peakrise Metal Co.,Ltd |

|

Verified Suppliers

|

|

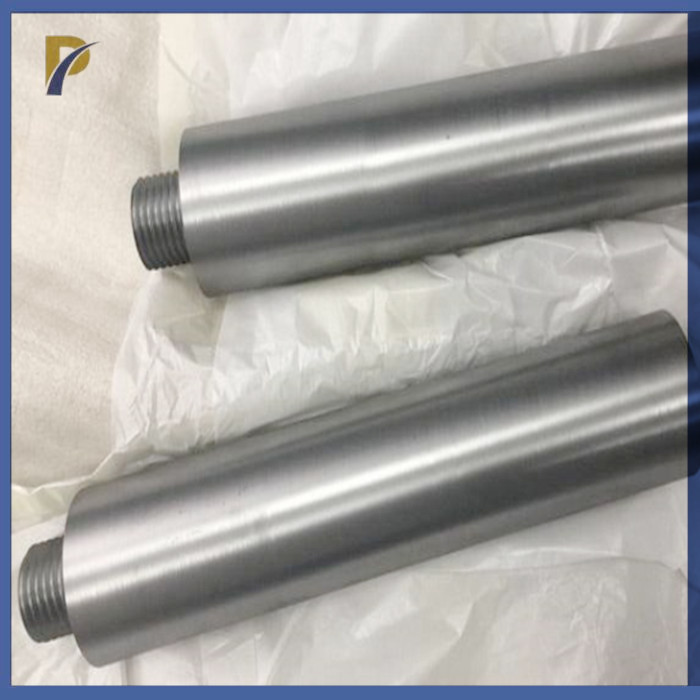

Diameter 63mm Molybdenum Electrode With Two End Male And Female Thread Of Glass Melting Furnace

1.Introduction Of dia63mm Molybdenum Electrode With Two End Male And Female Thread:

Molybdenum electrodes are currently used in many all-electric glass melting furnaces and flame-glass melting furnaces. The main reason is that the molybdenum electrode is a commonly used electrode for melting soda-lime glass, which has a high service temperature and surface current intensity, and the service temperature can reach 2000°C. In addition, the correct use and performance of molybdenum electrodes are important factors affecting glass manufacturing and prolonging the service life of glass melting furnaces.

After research, it is found that the greater the surface current density of the molybdenum electrode, the faster the loss. In the glass melting furnace, the surface current density of the molybdenum electrode is moderate at 1.0-0.7A/cm2, but when the melting furnace needs higher quality glass and longer electrode service life, a lower surface current density should be used. Among them, the highest surface current density of the molybdenum electrode should not be greater than 2A/cm2.

2. The Size Of dia63mm Molybdenum Electrode With Two End Male And Female Thread:

| Common diameter(mm) | 32mm,50mm,50.8mm,63mm,80mm |

| End thread size dia32mm | M20,thread length 40~45mm |

| End thread size dia63mm | M32, thread length 40~45mm |

| Tolerance of diameter | ±0.2mm |

| Tolerance of length | +0.5mm |

We also can process as per customer's drawing and reuqest.

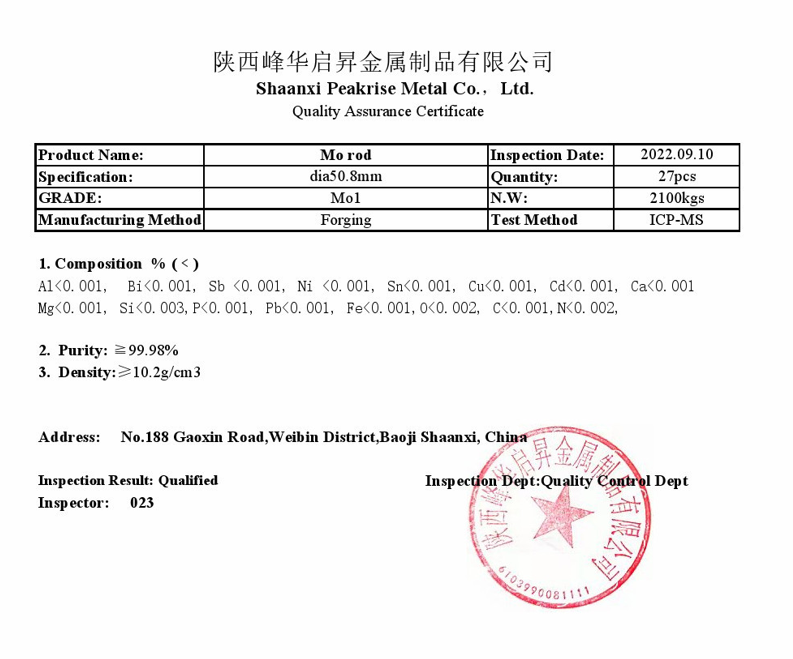

3. Effect of Molybdenum Electrode Purity on Glass Preparation:

The impurity content ratio of molybdenum electrode, the level of forging density and density uniformity are the most important indicators of its quality, and its impurity and density will also affect the preparation of glass. First of all, impurities mainly affect the transparency of the glass, the service life of the glass melting furnace and the molybdenum electrode. The melting point of metal compounds such as iron and nickel in the impurities is much lower than that of molybdenum and glass, so these impurities will melt into the glass, making the glass corrode the molybdenum electrode prematurely, so the glass produced has poor transparency and will cause The melting furnace failed and the molybdenum electrodes were easily broken.

Our purity can achieve 99.98%,and Our electrodes are highly recognized by customers and the quality is very good.

Glass electrode,polished molybdenum rod, end thread

Company profile:

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten and molybdenum non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tungsten alloy, molybdenum alloy and other items in excess of 100 different types. We started concentrating on foreign trade export business in 2010, providing high-quality non-ferrous metal products for the global market as a result of the industry's sharp increase in export sales. A comprehensive non-ferrous metal production enterprise that integrates manufacturing and processing, material research and development, product testing, and stock management has evolved throughout the years. Nearly ten years of growth serve as a reminder to us that providing high-quality goods and services will always be our first priority. At the same time, we are continuing to expand into new markets and serve more domestic and international clients while maintaining our high-quality standards. Exports of goods to Taiwan, the Ukraine, South Korea, the United States, Australia, Germany, Iran, and other nations have resulted in the development of long-lasting, positive cooperative relationships.

In addition to a variety of rolling mills, wire drawing machines, plasma welding rooms, lathes, milling machines, sawing machines, drilling machines, shears, stamping equipment, cutting equipment, grinders, straightening machines, CNC, etc., Peakrise Metal also has a variety of other production tools.

In order to ensure the traceability of each batch of products, we will establish documents for each batch of products to record the entire situation from production, delivery to customer feedback, thereby improving product quality and customer satisfaction.

Do you want to know more about our products?