Guangzhou Chuangyi Packing Technology Co., Ltd |

|

Verified Suppliers

|

|

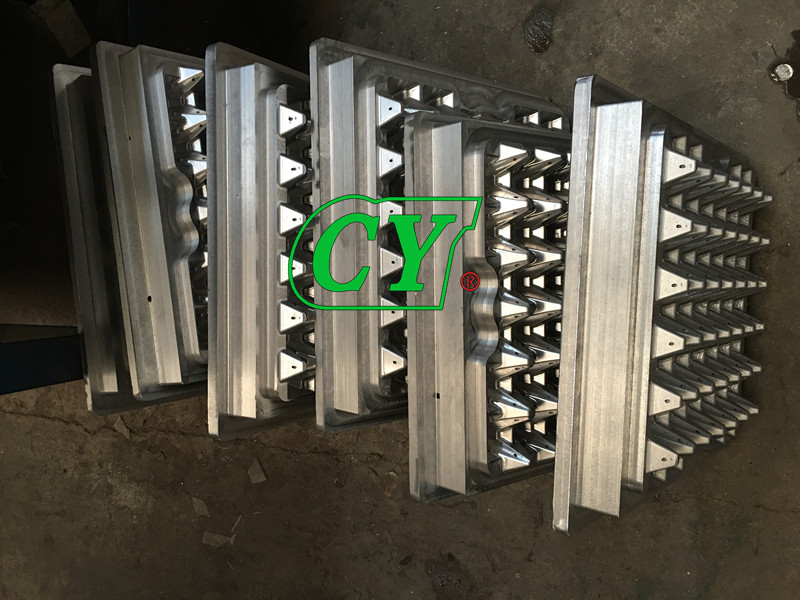

Die Casting Paper Pulp Mold 30 Cavity Paper Pulp Moulded Trays

30 Packed Egg Tray Mold Specifications:

1. It is 30 packed(30 Cavity) egg tray/ egg carton mold for making egg trays and egg cartons.

2. The molds will be installed on the forming machine for produce egg trays. By using vacuum, the forming mold of mahcine sucks the paper pulp, and close the mold to form the egg tray shape, then transfer mold transfers the egg tray on the drying machine or the net plate.

3. The raw material of mold is aluminum, it is corrosion resisitant. and we also have the copper and plastic for your choice.

4. The lifetime of egg tray mold is at lease 5 years.

5. The key of manufacturing paper tray products lies in the design and production of the corresponding moulds.

6. Our company has years of experience in moulds-making and large number of professional technicians as well as the advance CAD computerized design system and CNC mould processing equipment.

7. In a short time, we can offer a draft design of the moulds which we can make according to your requirement.

30 Packed Egg Tray Mold Specifications:

Product name | Egg tray mold |

Raw Material | Aluminum, Copper, Plastic |

Color | Original Color/ Colors |

Use | For Holding Eggs |

Delivery Time | 30 Days |

Size | Support Customize |

Shipping Way | By Sea, By Air |

1. Our mold is durable and easy for maintenance and replacement.

2. The price of our mold is reasonable comparable to its high

quality.

3. We make lineation before drilling holes to ensure all holes

distributed evenly. The holes size and spacing of holes of our

suction molds are better for high efficiency. We use stainless

steel mesh and use pre-forming technology when making them, this

make the molds looks better and increase the efficiency, and the

products produced are with better looking.

30 Packed Egg Tray Mold Drawings:

30 Packed Egg Tray Mold Applications: