Hunan Shuanghuan Fiber Molding Machinery Co., Ltd |

|

Verified Suppliers

|

|

Pulp Molding Machine Manufacturers Molded Pulp Machinery For Tableware

SHM pulp molding tableware machine is an advanced production line

that can produce biodegradable molded pulp tableware. The machine

uses a pulp molding process to form, shape, and trim the pulp, and

the drying process is completed with thermoforming drying and

pressing. The automatic thermal forming machine ensures that the

process is completed efficiently and with high precision. The end

product is a molded pulp tableware of high quality with excellent

performance.

| Features | Details |

|---|---|

| Forming Method | Automatic Reciprocating Vacuum Forming |

| Name | Biodegradable Molded Pulp Tableware Production Line |

| Warranty | 1 Year After Installation |

| Molded Pulp Process | Pulping, Forming, Shaping, Trimming |

| Weight | 12000kg |

| Type | Molded Pulp Machinery |

| Control System | PLC, Touch Screen |

| Delivery Time | 120 Working Days After Received Deposit |

| Molded Pulp Technology | Automatic Thermal Forming Machine |

| Voltage | Tabeware Pulp Molding Machine |

Pulp molding machines are known for their eco-friendly and

sustainable production process because they utilize recycled

materials and produce biodegradable and compostable products. They

are commonly used in industries such as food service, agriculture

(e.g., for fruit and egg packaging), and more, where disposable and

environmentally friendly tableware and packaging are in demand.

These machines come in various sizes and capacities, depending on

the production requirements of the manufacturer, and can produce a

wide range of products beyond just tableware and packaging,

including industrial components, electronics packaging, and more.

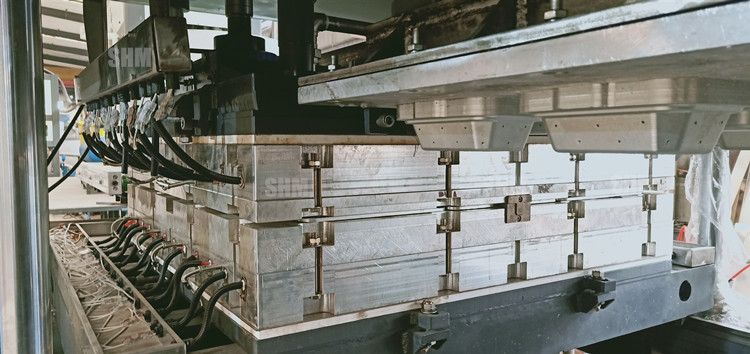

SHM has not only developed a variety of pulp molding machines but

has also dedicated itself to designing and manufacturing pulp

molding dies, hot pressing equipment, and hot press dies. We are

fully equipped to accommodate customized requests for pulp molding

production lines and molded pulp tray molds, including automatic

paper tray production lines, food tray molding machines, fruit tray

manufacturing machines, and more.

Packaging and Shipping of Pulp Molding Tableware Machine

What is a pulp molding tableware machine?

A pulp molding tableware machine is a type of industrial equipment

used to manufacture tableware and packaging products from

pulp-based materials. This process is often referred to as pulp

molding or pulp paper production. The machine takes raw materials

such as recycled paper, cardboard, or other cellulose-based

materials and converts them into various types of disposable or

biodegradable tableware items like plates, bowls, trays, and cups,

as well as packaging materials like egg cartons, fruit trays, and

more.

Here's a general overview of how a pulp molding tableware machine

works: