Shenzhen Johnhalm PDTec.,Ltd |

|

Available Drawings Format | stp, step, igs, iges, x t, sat, stl, sldxml, prt, ipt, dxf, dwg,

pdf, jpg, jpeg, png, etc |

Raw Material | Aluminum Alloy: ADC12, ADC10, A360, A380, A356, 6061, 6063 |

Manufacturing Service | CNC machining,milling,turning,grinding, wire EDM cutting,cnc

prototype/jig/fixture,laser cutting,other metal fabrication,likeStamping,Bending,Casting.etc. |

Tolerance | highest +/-0.005mm or +/-0.0002 inch |

Surface Roughness | Ra0.4 (milled or turned without polishing or grinding) |

Finish | polishing,mirror polishing,brushing, sandblasting, heat treatment

etc |

Surface Treatment | anodizing,blackening,electroplating(zinc,nickel,chrome),electrophoresis,

painting,powder coating,passivate,carburize etc. |

Logo | Laser engravina, CNC engraving, screen-printing etc. |

Commitment to quality

1. Continually maintaining and improving the effectiveness of our quality management system.

2. Periodic review of current quality policy and objectives to ensure its effectiveness and suitability.

3. Quality First and Service First is our pledge. In order to serve and support our clients better, we would establish a special team called Technology and Cost Team. So Best Practice ( top quality and competitive price ) will be submitted to you in the shortest time. We sincerely welcomes you and hopes to be the most suitable and steadiest partner of you.

4. We promise, and we do !

Advantages

1. Competitive Price

2. Quick Delivery time (2-4 weeks)

3. ISO Certificated with the strictest quality control system

4. Many Years OEM Mould-making and Plastic processing experience

5. Advanced equipment and Skilled workers

Product

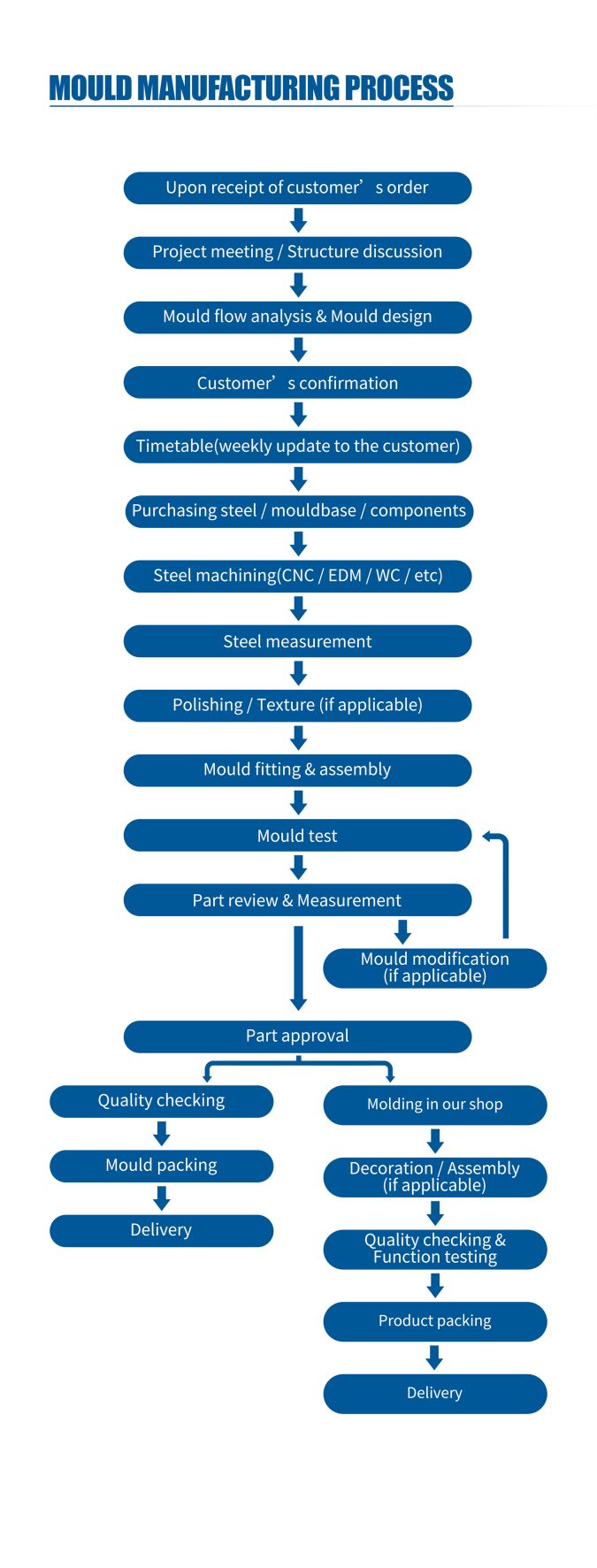

Mould Manufacturing Process

FAQ

1. How to ensure customers' drawings will not be disclosed to any third party?

We have the responsibility and obligation to not disclose the client's design and drawings to any third party without the customer's consent. So if necessary, the NDA (non-disclosure agreement) shall be signed for the good of mutual parties prior to the design or drawings issued.

2. What will you need from customer to come out with an offer or get into production?

The four Key elements as follows are the necessary document & information we need to get from customers prior to conclude a price or production.

- Drawings( 2D and 3D of IGES / STEP / PRT / X-T ,Solidworks ,etc )

- Raw Material ( a substituted material shall be adopted if the requested material is not available on the market.

- Surface finish or hot treatment

- Demand quantity. ( the quantity has very much to do with the price or even the processing methods could be different)

3. What is your MOQ (minimum order quantity)?

The Minimum order quantity is 1 piece. In principle, any small or mixed order is acceptable for us.