Suzhou Makeit Technology Co.,Ltd. |

|

Verified Suppliers

|

|

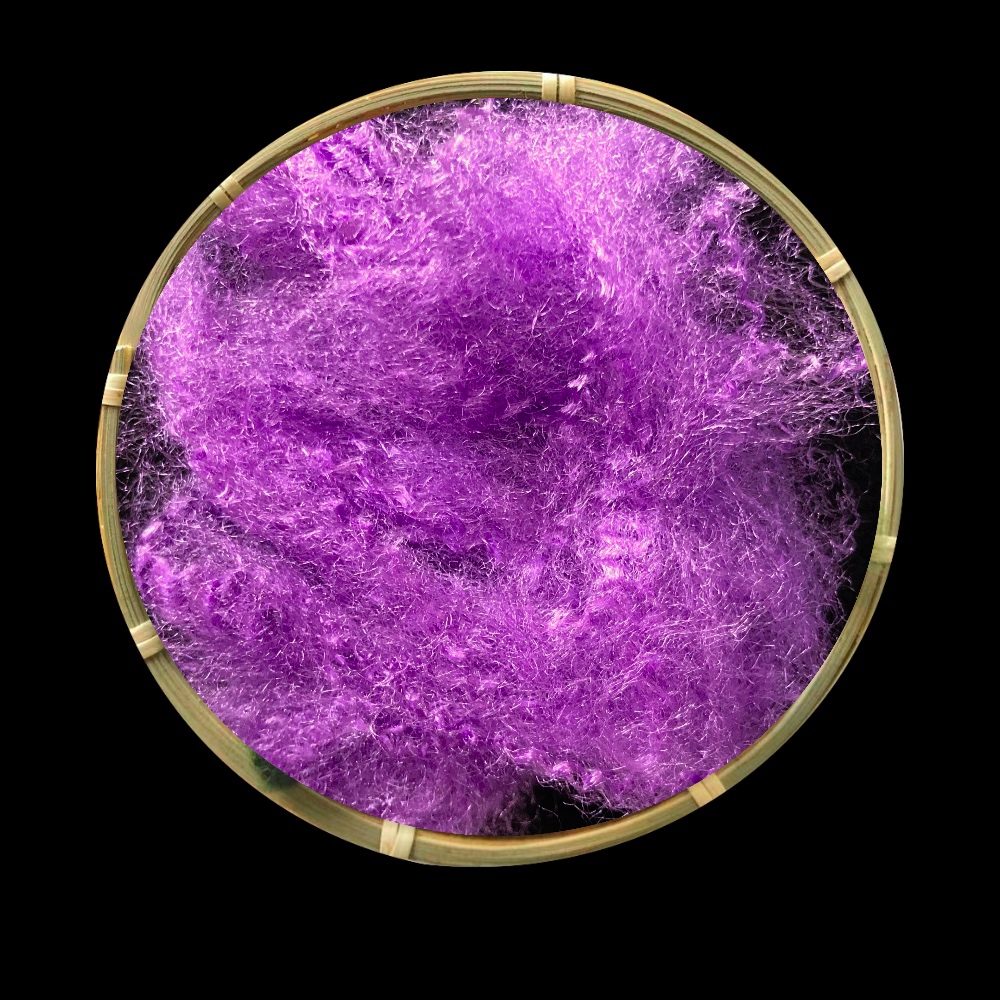

Full Dull Triangle Dope Dyed Polyester Staple Fiber With High Air Permeability

1.99detx*38mm Full Dull Purple Triangle Dope Dyed polyester satple fiber

1. Introduce

Triangle fiber is produced using good quality raw materials, import agent, special spinneret and improvement of technology, the cross section of this is an equilateral triangle.

Dope dyed fiber are “naturally beautiful”, without the need to be dyed afterwards, not only reducing the steps in printing and dyeing, saving energy, and reducing emission, but also delivering bright-colored textiles, uniform in color, endurable and not easy to fade in color during the consumption and use of its fiber products. Currently, compliance with environmental protection means following the trend, progressing with times.

Dope dyed refer to the colored fibers obtained via spinning process by adding coloring pigment in spinning solution ormelt. As known as non-dyed fibers or pro-spinning dyed fibers.

To process dope dyed fibers to textile products can omit the coloring procedure, with prominent features of reducing large amount of wastewater and carbon dioxide emission, save energy consumption and protecting environment. In this regard, the outstanding problems confronted by traditional printing and dyeing industry, such as high energy consumption, high water consumption and high COD emission, can be effectively solved from the source. Affectively solved form the source. According to statistics, compared with conventional polyester fibers, the dope dyed can save 89% of water consumption, 63% of energy consumption, 63% of chemical produce usage. 62% carbon dioxide emission and 67% COD emission.

At present, the dope dyed fiber shave a wide range of applications in industrial, clothing and household textiles, with most usage in automotive interiors, outdoor goods and embroidery threads, and increasingly wide usage in curtains, work clothes, leisure clothing and sportwear.

2. Specifications

| Name | Full Dull Triangle Dope Dyed Polyester Satple Fiber |

| Material | 100% polyester |

| Denier | 1.99Dtex |

| Length | 38MM |

| Color | Purple Water Grey, Royal blue, luxury silver, red, yellow etc. |

| Feature | Three lens formed by triangle polyester staple fiber cross section increase the refraction and reflection of light. The fiber has excellent flash and refraction properties, its blended fabric has the section like silk, elegant luster, the fouling resistance, abrasion resistance, good air permeability and good fluffy. |

3. Application

Equilateral triangle polyester staple fiber has larger surface area, faster dying, larger coloring quantity and better dyeing effect than normal fiber. The fouling resistance of fabric can be improved because of the increased amount of light reflex and small light transmittance for profiled section. Pilling phenomenon greatly reduces because of the large holding force of triangle fiber fluff. Triangle fiber has wear-resisting, good feeling and durable property. It also has good hygroscopicity, permeability, soft and elastic stiffness, can be made into bright triangle and cationic easy-dying (ECDP) triangle.

4. More pictures