Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd |

|

Professional Rotary Manure industrial dryer machine for Organic Fertilizer Production

Professional Rotary Manure Dryer for Organic Fertilizer Production

Introduction to Rotary Manure Dryer:

Due to high-humidity and sticky nature of poultry manure. Our

rotary dryers are optimized on the basis of regular rotary dryers,

making it more efficient to deal with high moisture and sticky

materials. the dryer was designed with higher Diameter/Length

ratio, unique flight distribution &shape and effective internal

breaking mechanism.

manure is rich in nutrients and trace elements that is a kind of

good organic fertilizer. Development of manure as compound organic

fertilizer, it is not only turning waste into wealth, but also

reducing environmental pollution and preventing spread of the

disease. It has good economic and social benefits. Our company

produces manure dryers which belong to compound organic fertilizer

production line equipment.

Structure and Working Principle of Rotary Manure Dryer:

Rotary manure dryer can reduce the water content (70% -80%) to safe

storage state(water content 13%). The whole process happens in a

closed system, thereby reducing pollution of the environment the

environment. Equipment mainly composed of screw dewatering machine,

hot air stove, feeder, feeding machine, rotary drum, discharging

machine, material crushing unit, fan, discharge and power cabinet;

after dehydration, the wet material entered the drying machine,

both in the drum cloth turning device copy board, the material

dispersed in the dryer full contact with the hot air to speed up

the drying heat and mass transfer . During the drying process, with

a gradient of copy material in the hot plate and under the effect

of temperament, to another section of the dryer exhaust discharge

valve star products.

Main Features of Rotary Manure Dryer:

1. With high degree of mechanization, it has a large production

capacity and continuous operation feature.

2. With Well-organized and convenient operating, materials are

running smoothly through the cylinder resistance.

3. Good quality, low power consumption and low maintenance costs.

4. Wide range of application; good uniformity of drying.

5. While drying the material, dryer can also achieve the purpose of

sterilization and deodorization.

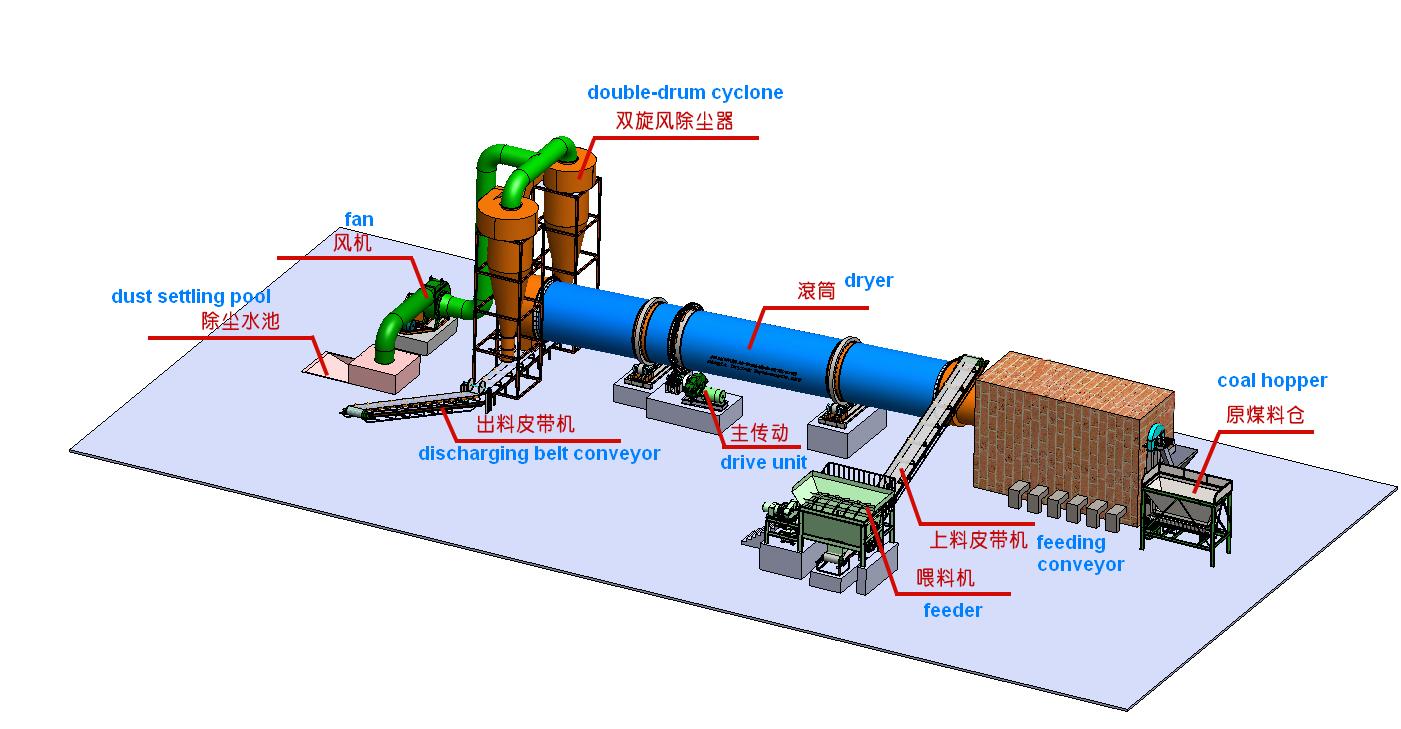

Typical Flowchart of Drying System:

Lipu workshop: