Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd |

|

Textile Chemical Sludge Dewatering Equipment , Staniless Steel Rotating Rotary Drying Machine

Ideal For: clay, DDGS, sewage sludge, textile chemical sludge,

painting sludge, animal feed, food waste, coal, oil sludge, farm

waste, coconut copra, fruit pomace, carob pulp, industrial waste,

etc.

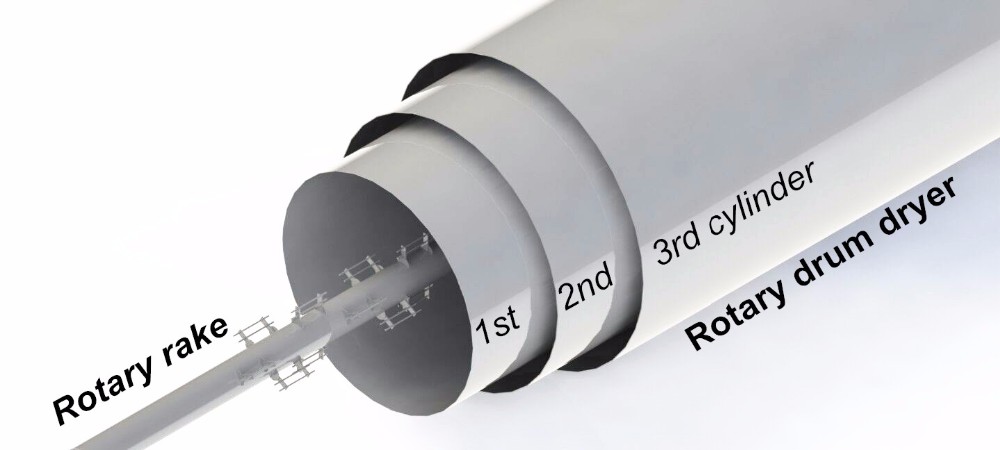

By analyzing the characteristics of sludge (includes moisture,

viscosity, water molecular structure, particle size, PH,

hygroscopicity, etc.), we adopt “Rotary Rake, triple-pass and large

volume hot air supply” drying technology in this sluge drying

equipment.

Based on the traditional structure of the rotary drum dryer, it adds scatter device along the axis of the cylinder. When

sludge material enter the cylinder: Firstly, the material is hit,

broken by the device in the process of falling, and then, it is

repeatedly grabbed, lift, fallen and beaten throughly. The surface

area of the shattered materials increased rapidly, and contact with

hot air sufficiently to transfer heat and mass. After multiple

level drying within three cylincer drum, it eventually meets the

drying requirements.

The drying effect is superior when compared with its previous

generation single-stage drum dryer.

A. Large capacity, continuous and stable operation;

B. High flexibility in operation, fast, efficient drying results;

C. Rotary speed and scattering device speed can be adjusted, and

can meet the requirements of different materials;

D. It can meet the drying requirement by choosing different

structure forms the copy board;

E. Because of the crushing effect on material scattering device,

the heat efficiency is improved;

F. Triple drum, triple energy efficiency.

Textile Chemical sludge dewatering Sludge Dryer Rotary Parameters:

| Product Name | Sludge Dryer |

| Producer | Shanghai Lipu Heavy Industry Co., Ltd |

| Voltage(v) | 380V or customized |

| Total motor power(kw) | According to Material’s Moisture |

| Early moisture(%) | 80±5% (Sludge before drying) |

| Final moisture(%) | 10%(adjusting) |

| Capacity(t/d) | 10t-200t |

| Suitable materials | All kinds of sludge |

| Application | Sludge drying |

| Usage | Reduce Material's Moisture |

| Weight(ton) | 50t |

| Matching Products | heat source, feeding machines, feeder, rotary drum, discharging machine, draft fan, discharge and power distribution cabinet. |