Luoyang Zhongtai Industrial Co., Ltd. |

|

Verified Suppliers

|

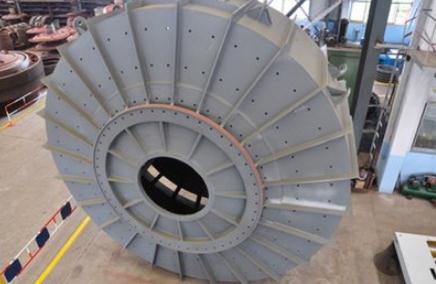

Mining Machine Mill MZ64×33 AG Mill And SAG Milll Ore Grinding Mill

1. Luo mine AG Mill | SAG Mill of ore grinding mill products is introduced

Luo mine AG Mill | semi autogenous grinding machine typical products: complete cooperation with Fuller company to make 1992 Ф 5.5 x 8.5 m the overflow type ball mill; With the diameter of 5.03×6.4m export ball mill completed in 1993; In 2001, the diameter of 4.27×6.1m export large mine mill was developed. In 2004, we cooperated with Metso to manufacture the largest semi-autogenous mill with Φ8.53×3.96. In August 2005, it was contracted by Jinchuan Group with the diameter of 5.5×8.5m overflow ball mill. In May 2006, the company contracted a Φ5.49×8.8m overflow ball mill for Anshan Steel Group. In 2006, it cooperated with Meizuo to manufacture Kunsteel Dahongshan autogenous mill. In July 2006 for Ling Steel Group contracted Φ8.0 ×2.8 m automill.

2. Luo mine AG Mill | SAG Mill advantage of ore grinding mill features:

Since the mill | semi autogenous grinding machine is the core of iron ore, non-ferrous metal ore dressing process equipment. Compared with the traditional crushing grinding equipment, Luo mine AG Mill | half since the grinding machine has the technological process is simple, save for two period of crusher and screening equipment), saving investment, short construction period, the advantages of simple operation, has been more and more recognition and use of the related enterprises at home and abroad, has a very broad prospects for development. The biggest feature of autogenous mill is that it can feed raw ore from stope or coarse crushed ore directly into the mill. Usually minerals are fed into the mill rod according to a certain proportion of grain size. The self-grinding machine can grind the material to -0.074mm at a time, the content of which accounts for more than 20% ~ 50% of the total product. The crushing ratio can reach 4000 ~ 5000, more than ten times higher than the ball and rod mill. Autogenous mill is a new type of grinding equipment which has both crushing and grinding functions. It uses the grinding material itself as the medium, through the mutual impact and grinding effect to achieve grinding, automill hence the name. Autogenous mill is also called no media mill.

3. Product parameters of ore grinding mil

Technical parameters of Luomine semi-autogenous mill

| Model |

Diameter of cylinder |

Length of cylinder | Effective volume (m3) | Mill speed (r/min) |

End cover structure form |

Drive mode | Motor | spec (Length × width × height) (m) | Approx weight (t) | Note | |

| Power (kW) | Rotate speed (r/min) | ||||||||||

| MZ24×10 | 2400 | 1000 | 4.5 | 22 | weld | edge | 55 | 740 | 7.8×3.5×3.3 | 18.5 | |

| MZ32×12 | 3200 | 1200 | 9.2 | 18.2 | weld | 160 | 740 | 8×4.1×3.7 | 32.8 | ||

| MZ40×14 | 4000 | 1400 | 16.6 | 17.6 | weld | 250 | 735 | 11.5×5×4.7 | 63 | ||

| MZ55×18 | 5500 | 1800 | 34.6 | 15 | cast | 800 | 167 | 14.1×7×6.3 | 178 | ||

| MZ64×33 | 6400 | 3300 | 107 | 12.8 | cast | 2000 | 200 | 23×10.3×9 | 306 | ||

| MZ75×25 | 7500 | 2500 | 107 | 11.4 | cast | 2000 | 200 | 23×10.5×10 | 355 | ||

| MZ85×40 | 8500 | 4000 | 225 | 102 | cast | 4850 | 200 | 27×14.2×12.9 | |||