Luoyang Zhongtai Industrial Co., Ltd. |

|

Verified Suppliers

|

|

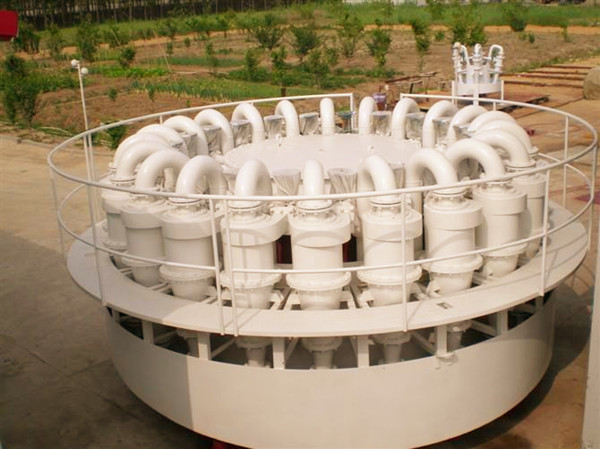

high efficiency low cost Hydrocyclone With Fine Particle Size Classification

Brief Introduction of hydrocyclone separator

1. Hydrocyclone is a kind of equipment used for grading the ore pulp by using centrifugal force. Lacking of motion and power unit, it needs to match with relevant slime pump. It is mainly used in ore dressing industries for grading, separating, concentrating and desliming.

2. Hydrocyclone shows the features such as low equipment cost, easy assembling and disassembling, convenient maintenance, less area covers and low cost of construction. In addition, there are some other advantages like large capacity of unit volume, treatment, fine separation size, high grading efficiency, the time and quantity of the ore pulp that staying in the cyclone is short and small. Therefore, it’s easy to operate when it stops working.

Usage of hydrocyclone :

A hydrocyclone is a device that separates mixture of uneven fluids, and it is a device that achieves the separation of two or multiple phases based on the density differential of two or multiple phases with the function of centrifugal force. Due to it that the strength of the centrifugal field is higher than that of the gravitational field, the separation efficiency of the hydrocyclone is higher than that of a gravity classifying device. Therefore, spiral classifiers applied frequently in the past have been replaced by hydrocyclones.

Features:

1.low equipment cost

2.easy mounting and dismantling

3.convenient maintenance

4.small floor space required

5.low capital expenditure

6.large processing capacity

7.a large fluctuation of process.

Technical parameters

| Standard | Inner diameter (mm) | Feeding caliber (mm) | Overflow pipe diameter (mm) | Sand setting caliber (mm) | Cone angle (.) | Maximum feeding granularity (mm) | Feeding pressure (Mpa) | Processing capacity (m3/h) | Separation size (μm) | Unit weight kg | |

| LKH-660 | 660 | 187,167 | 180,200, 220,240 | 80,110,150 | 20 | 16 | 0.03-0.4 | 250-360 | 74-220 | 950 | |

| LKH--500 | 500 | 130,120 | 130,140,160, 180,220 | 35,45,50,65, 70,80,90,100 | 25 | 10 | 0.03-0.4 | 140-220 | 74-200 | 416 | |

| 20 | 140-220 | 74-200 | 490 | ||||||||

| 10 | 74-150 | 556 | |||||||||

| LKH--350 | 350 | 80 | 80,90,105, 115,120 | 30,35,40,45, 50,60,70 | 25 | 6 | 0.03-0.4 | 60-105 | 50-150 | 135 | |

| 20 | 0.03-0.4 | 50-150 | 155 | ||||||||

| 15 | 0.03-0.4 | 50-120 | 230 | ||||||||

| LKH--300 | 300 | 64,75 | 65,80, 100,120 | 20,25,30, 35,40 | 20 | 5 | 0.03-0.4 | 45-90 | 50-150 | 88 | |

| 15 | 0.03-0.4 | 40-100 | 169 | ||||||||

| LKH--250 | 250 | 55,74,80 | 60,75,80, 100,120 | 16,18,20,25, 30,35,40 | 20 | 3 | 0.05-0.4 | 40-65 | 40-100 | 63 | |

| 15 | 40-100 | 120 | |||||||||

| 10 | 30-100 | 123 | |||||||||

| LKH--200 | 200 | 48 | 40,50, 55,65 | 16,20,24, 28,32 | 20 | 2 | 0.05-0.4 | 25-40 | 40-100 | 36 | |

| 15 | 30-100 | 64 | |||||||||

| LKH--150 | 150 | 36 | 30,35, 40,45 | 8,10,12,14, 16,18,20,22 | 20 | 1.5 | 0.05-0.4 | 11-20 | 30-74 | 22 | |

| 15 | 30-74 | 20 | |||||||||

| 8 | 20-74 | 60 | |||||||||

| LKH125 | 125 | 26 | 25,30, 35,40 | 8,10,12, 14,16,18 | 17 | 1 | 0.05-0.4 | 8-15 | 20-100 | 10 | |

| 8 | 20-74 | 12 | |||||||||

| LKH--100 | 100 | 23 | 20,25, 30,40 | 8,10,12, 14,16,18 | 20 | 1 | 0.05-0.4 | 5-12 | 20-100 | 8 | |

| 15 | 10-100 | 5 | |||||||||

| 8 | 10-74 | 6 | |||||||||

| LKH--75 | 75 | 13 | 15,17,20 | 6,7,8, 10,12 | 15 | 0.6 | 0.1-0.5 | 2-5 | 20-74 | 4 | |

| 7 | 0.1-0.5 | 5-40 | 7 | ||||||||

| LKH--50 | 50 | 9 | 11,13, 15,18 | 3,6,8, 10,12 | 15 | 0.3 | 0.1-0.5 | 1.5-3 | 10-74 | 2 | |

| 6 | 5-30 | 2.5 | |||||||||

| LKH--25 | 25 | 5 | 5,6, 7,8 | 2,3,4,5 | 5 | 0.2 | 0.1-0.5 | 0.3-0.1 | 3-10 | 0.8 | |

| 3 | 0.3-0.1 | 2-10 | 1.4 | ||||||||

| LKH--10 | 10 | 2 | 2,3,4 | 12 | 4 | 0.1 | 0.1-0.1 |