Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

VSM0613 mini 6mm diameter 9 teeth gear permanent magnet stepping motor

Description:

This is 6mm diameter permanent magnet stepper motor attached with a gear on shaft.

The modulus of gear is 0.2, and the motor is 9 teeth.

We can remove the move if customers do not need it.

The torque of 6mm motor is about 1 g*cm range, if customers need higher torque, please consider bigger size such as 10mm and 8mm motors.

The connector is Molex 51021-0400 (1.25mm pitch connector), we can replace it with other connector types if you want to.

Motor parameters:

| Model No. | VSM0613 |

| Motor type | Bipolar permanent magnet motor |

| Phase No. | 2 phases |

| Rated voltage | 3.3 V DC |

| Step angle | 18° |

| Resistance | 12Ω |

| Connector type | Molex 51021-0400 |

| Pull-out torque | 1g*cm (800PPS) |

Gear parameters:

| Modulus | 0.2 |

| Pressure angle | 20° |

| Teeth | 9 |

| Reference cir cutle | Φ1.8 |

| Modification coefficient | 0.1 |

| Precision | JGMA4 |

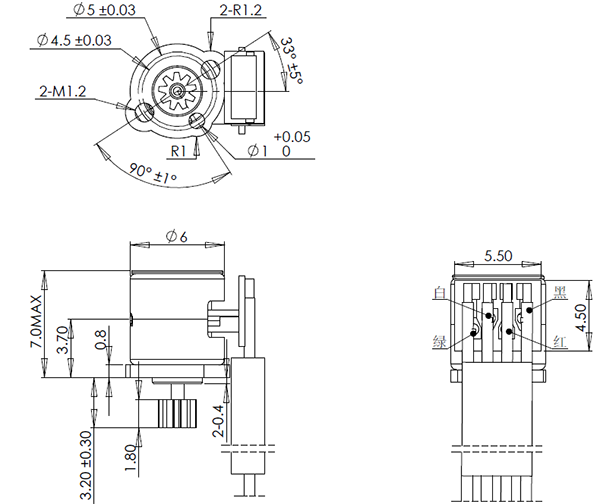

Design drawing:

Product display:

Application of stepper motors:

Stepper motors are used for precise control, widely used on medical equipment, 3D printer, industrial precise control, automation equipment, etc.

Stepper motors can be used in any mechanisms requirement precise conrtol and rotational/linear movement.

Advantage of stepper motors:

Stepper motor can reach precise control even without close-loop encoders / without feed back system, also they do not have electrical brushed. Thus there is no electromagnetic interference and electrical sparks issues. In some cases, they can replace DC brushed motors/ brushless motors.

Stepper motors are easy to control with drivers, and this feature establish its important position in the field of precise control.

1. Precise control achievable, programmable

2. Without electromagnetic interference & electrical sparks

3. Small size

4. Reasonable price

5. Low noise

6. Long service life