Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

10-816G-M3 Gearbox Reducer Stepper Motor With Adjustable M3 Lead

Screw Shaft

Description:

This is a 10mm diameter stepper motor attached with a 10*12mm

gearbox.

Output shaft is standard M3 lead screw shaft, and we can also

change it into D shaft.

Lead screw length is adjustable, based on customer’s own need.

We have multiple gear ratio for option, from 2:1 to 1000:1.

With a bigger gear ratio, output torque is bigger, and output speed

is slower.

Customer need to choose a suitable gear ratio first.

We have two different coil resistance: 20Ω/ 40Ω

With higher resistance, motor will have higher rated voltage.

Motor Parameters:

| Model No. | 10-816G-M3 |

| Motor type | 10mm stepper motor |

| Output shaft | M3*0.5P |

| Coil resistance | 20Ω/40Ω |

| Step angle | 18°/step angle |

| Rated voltage | 3.3~5V DC |

| Phase No. | 2 phases (4 wires) |

Gearbox Parameters:

| Gear ratio | 2:1 | 5:1 | 10:1 | 15:1 | 20:1 | 30:1 | 36:1 | 50:1 | 63:1 | 67:1 | 89:1 | 100:1 |

| Precise ratio | 2.002 | 4.995 | 9.677 | 14.754 | 20.501 | 29.120 | 36.122 | 51.103 | 63.071 | 66.801 | 89.227 | 99.002 |

| Tooth number | 23 | 20 | 13 | 18 | 15 | 12 | 20 | 20 | 14 | 17 | 14 | 13 |

| Gear levels | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 |

| Efficiency | 80% | 80% | 80% | 72% | 72% | 72% | 65% | 65% | 65% | 65% | 65% | 65% |

| Gear ratio | 110:1 | 150:1 | 172:1 | 210:1 | 250:1 | 275:1 | 298:1 | 380:1 | 420:1 | 500:1 | 600:1 | 1000:1 |

| Precise ratio | 110.407 | 150.948 | 171.883 | 210.591 | 250.111 | 274.403 | 297.924 | 387.689 | 421.296 | 506.155 | 599.394 | 986.406 |

| Tooth number | 12 | 18 | 13 | 12 | 13 | 12 | 12 | 12 | 12 | 18 | 16 | 12 |

| Gear levels | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 7 | 7 | 7 |

| Efficiency | 59% | 59% | 59% | 59% | 59% | 59% | 59% | 59% | 59% | 47% | 47% | 47% |

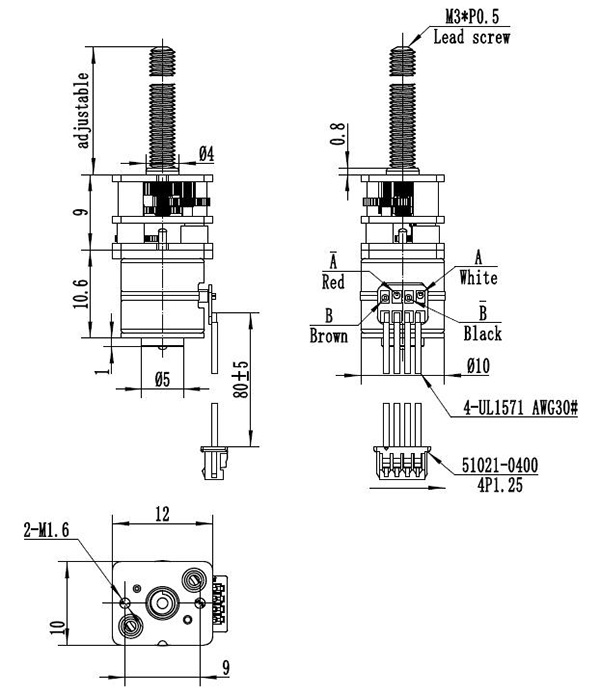

Design drawing:

Product display:

Application of stepper motors:

Stepper motors are used for precise control, widely used on medical

equipment, 3D printer, industrial precise control, automation

equipment, etc.

Stepper motors can be used in any mechanisms requirement precise

conrtol and rotational/linear movement.

Advantage of stepper motors:

Stepper motor can reach precise control even without close-loop

encoders / without feed back system, also they do not have

electrical brushed. Thus there is no electromagnetic interference

and electrical sparks issues. In some cases, they can replace DC

brushed motors/ brushless motors.

Stepper motors are easy to control with drivers, and this feature

establish its important position in the field of precise control.

1. Precise control achievable, programmable

2. Without electromagnetic interference & electrical sparks

3. Small size

4. Reasonable price

5. Low noise

6. Long service life

Stepper motors are widely used among all industries.