Changzhou Vic-Tech Motor Technology Co., Ltd. |

|

Verified Suppliers

|

|

SM0818 motor is a 8 mm diameter stepper motor with M2*0.4P lead screw on top.

This is M2 standard lead screw, customers are free to customize lead screw’s type and length.

For example, lead screw could be replaced with M3 lead screw.

Other parameters such as cable length and resistance are all customizable.

The application fields of 8mm miniature stepping motors include but are not limited to:

Smart security products: 8mm stepping motors are widely used in security cameras, CCTV cameras and intelligent locks for their high torque and precision. They can achieve precise rotation and positioning needed by these devices.

Camera lenses: Thanks to their compact size and stable performance, 8mm stepping motors can precisely rotate and adjust camera lenses to achieve auto-focus functions. They are key components inside DSLR lenses, lens modules and lens turrets.

Wearable devices: As wearable technology develops, there is an increasing demand for small size and low power motors. The 8mm stepping motor, with its miniature size and efficiency, can power rotating parts in wearable gadgets like smartwatches, AR glasses, robotic limbs, etc.

Door locks: The high torque performance of 8mm stepping motors enables them to repeatedly drive locking mechanisms of smart door locks at a precise angle. This ensures smooth and accurate locking and unlocking operations.

due to their small size, low power consumption and precise positioning capability, 8mm stepping motors have found wide use in various applications requiring compact motors with stable performance, especially in the fields of smart home, IoT, robotics and automation.

| Model No. | SM0818 |

| Motor type | 8mm linear stepper motor |

| Rated voltage | 5V DC |

| Coil resistance | 6Ω(customizable) |

| Lead screw type | M2*0.4P |

| Lead screw length | 12.5mm(customizable) |

| Drive mode | 2-2 phase excitation |

| Step angle | 18° |

| Pull-out torque | >3.5g*cm at 500 PPS |

| Drive mode | 2-2 phase excitation |

Competitive Advantage

Small size: At only 8mm in diameter, these motors are remarkably compact compared to standard sized motors. Their small size makes them suitable for applications where space is limited.

Low power consumption: Due to their simple and miniaturized structure, 8mm stepping motors consume very little power, This low power draw enables longer battery life in portable devices.

Precise positioning: Stepping motors achieve positioning by receiving stepping pulses. The 8mm motors can offer high stepping angles from 0.9 to 1.8 degrees, realizing precise rotation and accurate positioning.

Easy to control: These motors are driven by open-loop control, meaning they can be easily controlled with a simple logic signal from a microcontroller. No feedback mechanism is required. This makes their control simple and cost-effective.

Stable performance: Due to their sturdy and robust construction,

8mm stepping motors can deliver consistent performance over long

usage times and under various conditions.

the key benefits of 8mm stepping motors lie in their ability to offer high torque and precise positioning within an extremely compact package. Their low power consumption, easy controllability and stable performance further enhance their suitability for miniaturized applications where space and efficiency are at a premium. These features make them ideal choices for industries focusing on size reduction and integration.

Motor input method with Pin type, FPC, PCB, Lead wire etc.

These can be customized according to customer needs.

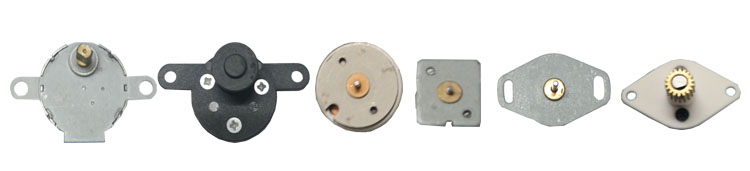

The regular models are shown in the figure, and the special sizes can be customized.

Lead Time and Packaging Information:

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of

customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by

express

Mass production, motors are packed in corrugated cartons with

transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets