Shandong Chuangxin Building Materials Complete Equipments Co., Ltd |

|

Verified Suppliers

|

|

Full Automatic Construction Material Making Machinery Magesium Oxide Sheets Production

Product Description

The production line adopts the technology of double-drive double-roller extruding, and the product is formed once after sizing, material feeding, spreading no-woven cloth, compounding and repressing. fireproof mgo board production line runs stably with high automatic degree,the specification of its product can be adjusted arbitrarily.

The equipment actually realizes the industrial production line of

new model building wall board, and the boards have even and glazed

surface with high compactness.The equipment largely reduces the

labor intensity of worker and thoroughly changes many shortages of

the former casting forming with upright mould or flat mould, such

as large mould usage, low recycling rate, required electrical

heating or steam heating, single kind of product as well as the sound insulation and heat-preserving which don’t meet them

market requirements.

There is not any requirement about high temperature and high pressure during production processing. The board will be formed at one time after roller-extruding under the conditions of normal temperature and normal pressure.This is a green environmental-protection project, because that there is no waste water, waste materials and waste gas during its production processing. The finished board don’t need high temperature drying, air-drying and watering,and under the normal temperature, they will dry well indoor.

Advantages | ||

Number | Item | Content |

1 | Low cost | Low labour and raw materials costs |

2 | Long life | Up to 30 years |

3 | Recycling use | Reused for more than 8 times |

4 | Environment protection | Environment-friendly raw materials used |

5 | Flexible layout | adjusted according to your requirement |

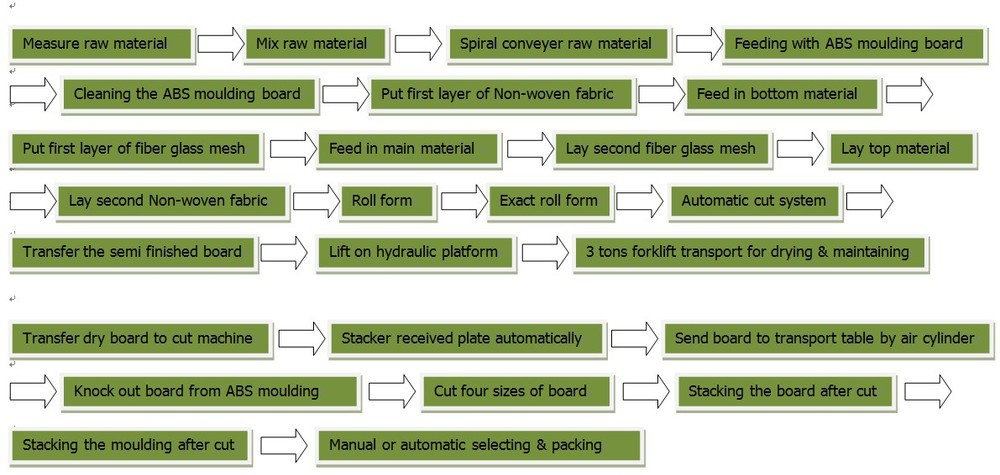

This automatic mgo board production line in China is made up of two parts, Board making machine line and Board four-sides cutting machine Line

The production line is composed of board-making

machine,glue-spreading and veneering-drying machine and

glazing machine.according to the production and the automatic

degree, this production line is divided into 6

models and three specifications ,such as large ,middle and small

specification.The production line for mgo board

has :production workshop ,finished product workshop and raw

material warehouse . workshop:100---1000m2,

worker:3---6person,water:ordinary

water,electricity:1.1—10KW(according to different scale)

Our company provides mgo board production line design ,cost

accounting,installation and operation,equipment maintenance and the

whole life cycle techincal support.

2) complete data specification

Provide production line equipment technical data and

instructions,and provide the mgo board production line formula.

3) quality commitment

The company regards product quality as the lives of enterprise,the

main components and wearing parts are made of high quality

wear-resistant materials and advanced processing technology,so that

the equipment endurable and wear

resisting ,wearing parts warranty for one year.

4) Trade service

We can help the customer to do the consignment and the relevant

procedure for import and export.

Q1.What’s your advantage? Why we choose you?

A:1)10 Years experience of test pen production and R&D.We have

the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to

customer requirements, We support the customized.

3)The project is envoronmental protection.The main raw materials

are from gricultural and industrial waste, such as crops straw,

sawdust, fly ash, sand and etc. The products are absolutely

ecological and low cost.

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients

from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty of your equipment?

A:1 Year.

Q5.Do you supply spare parts?

A:Excellent easy broken parts support for buyers. Easy broken parts

guarantee for one year.

Q6.Will you provide training?

A:The training is free of charge , and our engineer will be on duty

to train your worker.

Q7:How will you provide installation&commissioning?

A:Will provide 2~8persons(adjustable according to the degree of

automatic )for installation.

| capacity | 2000 sheets |

| power | 200kw |