Xi 'an Dongmeng Steel Co., Ltd |

|

316 316l 430 Metal Stainless Steel Sheet Coil Astm JIS stainless steel sheet metal 4x8

The difference between stainless steel hot rolling and cold rolling is that cold rolling is rolled on the basis of hot rolling.

Cold rolling: is in hot rolled stainless steel plate rolled out on the basis of processing, generally speaking, hot rolling, pickling, cold rolling such a process. It is called cold rolling even though the steel plate is heated by rolling in the process. Due to the cold rolling after continuous cold rolling, the mechanical properties are poor and the hardness is too high. Must undergo annealing to restore its mechanical properties, no annealing is called rolling hard coil. Hard roll is generally used to make products without bending or stretching.

Its features:

1. Cold rolled steel plate has a certain degree of work hardening, low toughness, the price is more expensive;

2. Cold rolling processing surface without oxide, good quality;

3. Products made of cold deformation have high dimensional accuracy and good surface quality;

4. Due to its production process, cold rolling is widely used in all walks of life, such as all kinds of cold stamping parts, cold rolling cold extrusion profiles, cold coil springs, cold drawn wire, cold heading bolts and so on.

Hot rolling: is relative to cold rolling, cold rolling is rolling below the recrystallization temperature, and hot rolling is rolling above the recrystallization temperature.

Its features:

1. Poor toughness and surface smoothness, low price;

2. The temperature of hot rolling is similar to that of forging;

3. Hot plate using hot tie processing surface with oxide skin, plate thickness is lower;

4. Because of its production technology, it is widely used in civil use, such as kitchen utensils, general household appliances, etc.

5. Hot rolled steel plate, mechanical properties are far less than cold processing, also inferior to forging processing, but has good toughness and ductility.

Stainless steel plate specification

| Name | Thickness | Width | Length |

| Thin plate | 0.2mm-4mm | 1000mm 1219mm 1500mm 1800 mm 2000mm | 2000mm 2438mm 3000mm 6000mm-12000mm |

| Medium plate | 4mm-20mm | 1000mm 1219mm 1500mm 1800 mm 2000mm

| 2000mm 2438mm 3000mm 6000mm-12000mm

|

| thick plate | 20mm-115mm | 1000mm 1219mm 1500mm 1800 mm 2000mm

| 2000mm 2438mm 3000mm 6000mm-12000mm

|

| Common materials:201,202,301,304,309(S),310(S),316(L),321,409,410,430,etc. | |||

| If the customer's demand is large, we can cut it according to the customer's size Another can do wire drawing plate, anti - slide plate, electroplating plate. | |||

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel plates meet the requirements, the steel plates must undergo heat treatment such as annealing, solution treatment and aging treatment before delivery. It is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy and other industries, as well as various parts of buildings, kitchenware, tableware, vehicles and household appliances. | |||

Stainless steel plates are classified according to surface smoothness

| Surface | Features | Summary of manufacturing methods | Purpose |

| NO.1 | Silver white matte | Hot rolled to specified thickness | Use without surface gloss |

| NO.2D | silvery white | Heat treatment and pickling after cold rolling | General material, deep drawing material |

| NO.2B | Gloss stronger than No.2D | After No.2D treatment, the final light cold rolling is carried out through the polishing roller | General material |

| BA | Bright as a mirror | Bright annealed surface processing, high surface reflectance. | Building materials, kitchen utensils |

| NO.3 | Rough grinding | Grind with 100 ~ 200# (unit) abrasive belt | Building materials, kitchen utensils |

| NO.4 | Intermediate grinding | A polished surface obtained by grinding with 150~180# abrasive tape | Building materials, kitchen utensils |

| NO.240 | Fine grinding | Grinding with 240# abrasive belt | kitchen utensils |

| NO.320 | Very fine grinding | Grinding with 320# abrasive belt | kitchen utensils |

| NO.400 | Gloss close to ba | Grind with 400# polishing wheel | General materials, building materials, kitchen utensils |

| HL | Hair lines | There are a lot of grinding particles in hair line grinding (150 ~ 240#) with appropriate particle materials. | Building materials |

| NO.7 | Close to mirror | Grinding with 600# rotary polishing wheel | For art and decoration |

| NO.8 | Mirror | The mirror is ground with a polishing wheel | Reflector, decorative |

Coloured stainless steel plate

n recent years, color stainless steel plate has been used more and more widely because of its uniqueness. Now, a large number of colored stainless steel products are used abroad to decorate the building, and colored stainless steel plate has become all the rage. Chinese colored stainless steel not only has the unique luster and strength of metal, but also has a colorful, long-lasting color. Color stainless steel plate it not only maintains the physical, chemical and mechanical properties of primary stainless steel, but also has stronger corrosion resistance than primary stainless steel. Therefore, when it came out from the 1970s, it has been widely used in building materials, chemical industry, automobile, electronic industry and arts and crafts.

Austenitic stainless steel is the most suitable coloring material in common primary stainless steel, which can obtain a satisfactory color appearance. Ferritic stainless steel will increase the possibility of corrosion in the coloring solution, the color is not as bright as the former. And low chromium high carbon martensitic stainless steel, because of its worse corrosion resistance, can only get dark color or black surface. It is reported that austenitic stainless steel after being colored by low temperature surface oxidation treatment coloring method, exposed in the industrial atmosphere for 6 years, exposed in the Marine atmosphere for 1 and a half years, soaked in boiling water for 28 days, or heated to 300℃ or so, its color luster has no change. In addition, it can also withstand general molding, drawing and bending processing and work hardening. WiQ Industrial Design. At present, in China, colored stainless steel can be used in many other fields besides building walls and window frame decoration. For example, black stainless steel panels can be used to make solar panels, which can be selected to achieve a heat absorption rate of 91% to 93%. In the arts and crafts, the combination of color stainless steel and printing, can use etching and grinding and mesh point method with the process, the production of fadeless three-dimensional relief fresco, hanging screen. Additional, make household electric appliance, cooker, kitchen equipment, toilet appliance with color stainless steel, will be loved by consumer.

Corrosion resistance:The corrosion resistance of stainless steel plate mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and internal structure. Chromium plays a major role. Chromium has high chemical stability, can form a passive film on the steel surface, isolate the metal from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

High temperature oxidation resistance:Stainless steel plates have high-temperature oxidation resistance, but the oxidation rate will be affected by inherent factors such as exposure environment and product form.

Physical property:High strength stainless steel plate with excellent toughness has processing properties such as bending, welding and stamping.

Element function

The corrosion resistance of stainless steels decreases with increasing carbon content. Therefore, most stainless steels have low carbon content of up to 1.2%, and some have ω C (carbon content) even lower than 0.03% (e.g. 00Cr12). The main alloying element in stainless steel is Cr (Chromium), and only when Cr content reaches a certain value, the steel has corrosion resistance. Therefore, stainless steel Cr (chromium) content is generally at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

Carbon (C) : 1. Improve the deformation resistance and tensile strength of the blade; 2. Enhance hardness and improve wear resistance.

Chromium (Cr) : 1. Enhanced hardness, tensile strength and toughness; 2. Prevent wear and corrosion.

Cobalt (Co) : 1. Increase the hardness and strength, so that it can withstand high temperature quenching; 2. Used in more complex alloys to enhance certain individual properties of other elements.

Copper (Cu) : 1. Enhance corrosion resistance; 2. Enhance wear resistance.

Manganese (Mn) : 1. Increase quenchability, wear resistance and tensile strength; 2. Removal of oxygen from molten metal by separate oxidation and separate vaporization; 3. When added in large quantities, the hardness is enhanced, but the brittleness is improved.

Molybdenum (Mo) : 1. Enhanced strength, hardness, hardenability and toughness; 2. Improve machinability and corrosion resistance.

Nickel (Ni) : 1. Enhance strength, hardness and corrosion resistance.

Phosphorus (P) : enhances strength, machinability and hardness.

2. It is easy to crack when the concentration is too high

Silicon (Si) : 1. Enhanced ductility; 2. Increase the tensile strength; 3. Removal of oxygen from molten metal by separate oxidation and separate vaporization.

Sulphur (S) : Use in small quantities to improve machinability.

Tungsten (W) : Increases strength, hardness and toughness.

Vanadium (V) : increases strength, hardness and seismic resistance.

| Elemental compositions and PREN values of four tested stainless steels | ||||||||||||

| steel | Cr | C | Ni | Mn | Si | P | S | Mo | N | Cu | Fe | PREN |

| 316 | 16.9 | 0.05 | 10.6 | 16.0 | 0.50 | 0.031 | 0.006 | 2.05 | - | - | Bal | 23.665 |

| 904L | 20.1 | 0.02 | 25.3 | 2.00 | 1.00 | 0.045 | 0.035 | 4.04 | - | 1.32 | Bal | 33.432 |

| 254sMo | 19.7 | 0.02 | 17.8 | 1.00 | 0.08 | 0.03 | 0.01 | 6.20 | 0.19 | 0.75 | Bal | 43.2 |

| 2507 | 25.4 | 0.03 | 7.01 | 1.00 | 0.08 | 0.035 | 0.02 | 4.20 | 0.27 | 0.50 | Bal | 43.58 |

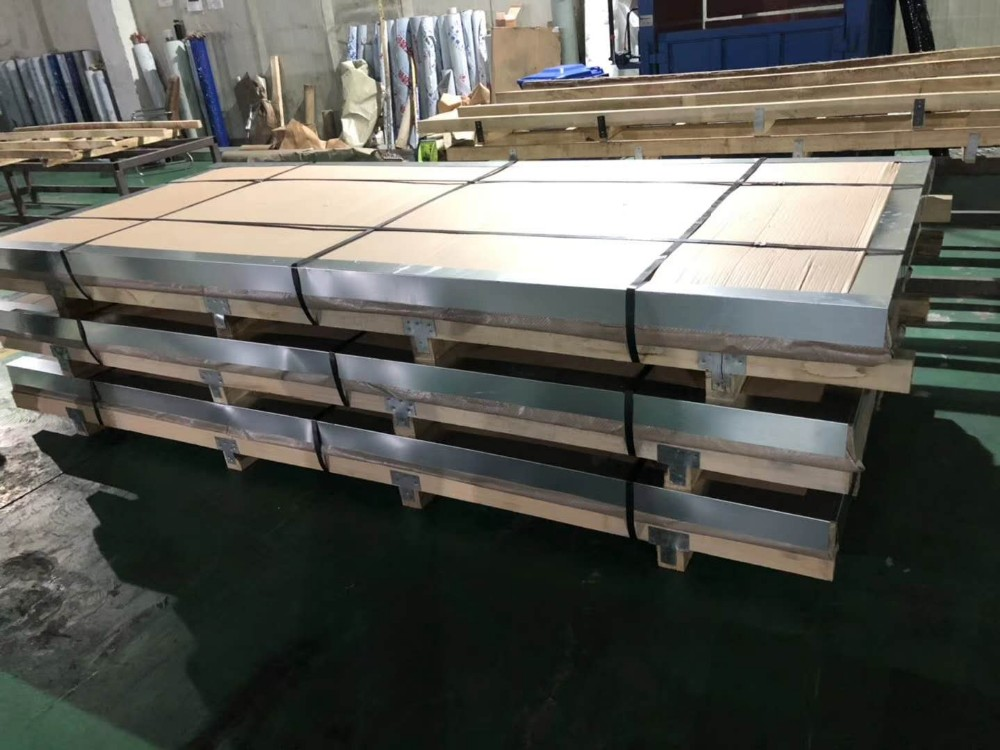

Packaging:

1 .Sheets covered with wooden plate for protection in transportation.