Wuxi Zhongborui Machinery Co. Ltd. |

|

4Kw Metal Cold Roll Forming Machine / Rolling Shutter Making Machine With Cycloidal Reducer

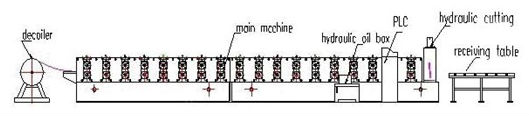

Work flow:

Uncoiling→Feeding material into machine→Roll forming→Measuring

length→ Auto cutting→Products receiving

| Suitable material | Color steel sheet , galvanized steel sheet, |

| Main motor power | 4KW with Cycloidal reducer |

| Hydraulic station power | 3KW |

| Hydraulic oil | 40# |

| Thickness of material | 0.3mm~0.8mm |

| Diameter of principal axis | Φ70mm |

| Material expand width | 1000mm-1250mm |

| Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| Material of roller | High grade 45# forged steel (plated chrome plating on surface) |

| Rolling galvanization thickness | 0.05mm |

| Processing speed | 0-12m/min |

| Processing precision within | 10m+/-1.00mm |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Kind of drive | 1 inch chain link bearing model 6210 |

| Roller station | 11/15 Roller Statio |

Components and Technical Specification

1. Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a

turnable way. The steel coil is uncoiled by hand. Loading

capacity:1.2T

Inner diameter: 500-508mm

2. Feeding Table

Put the raw material(steel plate) through the beach to manufacture

and process, it can guarantee that the products are neat, parallel

and everything is uniformity. Please refer to the equipment

regulation to know the function of locate angle iron.

3. Hydraulic System

Power:4kw,Hydraulic oil: 40#hydraulic oil into the hydraulic oil tank ,the pump drive the

cutter machine to begin the cutting job.

4.Computer Control Cabinet

The target piece`s length is adjustable and digit of it can be

adjusted. Computed mode has two modes: automatic and manual one.

The system is easy to operate and use.

PLC:EURA

5.Cutting System:

It adopts the hydraulic drive and automatic location to decide the

dimension and cut the target products.

Material of blades: Cr12,quenching treatment

6.Output Table

It adopts welded steel and supported roller to transmit the

products,which is used to collect the finished products.

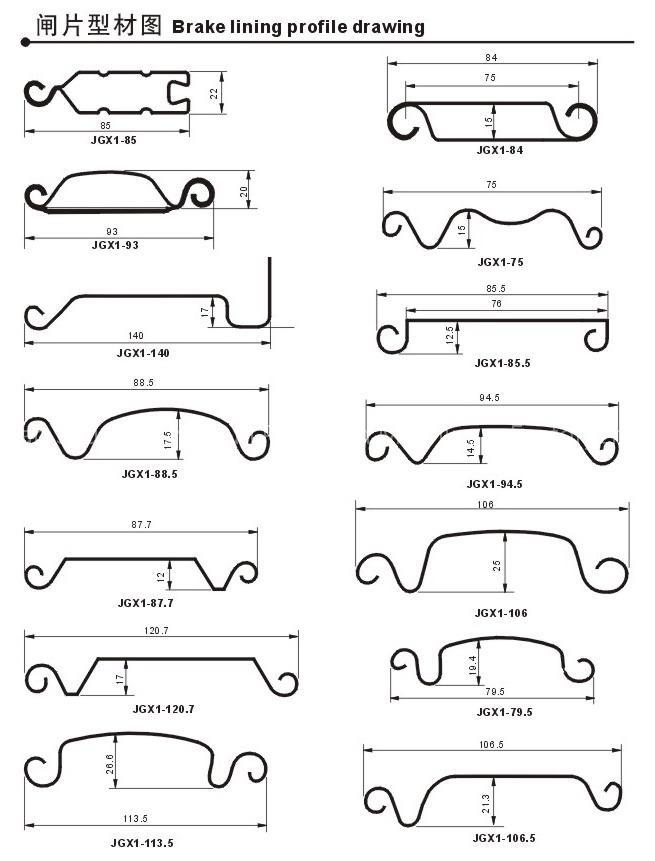

Profile Drawing