Jiangyin Dingbo Technology CO., Ltd. |

|

Crash Barrier Roll Forming Machine Highway Guardrail with Hydraulic Post Cutting System

Main feature

Metal road guardrails is made from hot rolled steel strips, and straightened, holes punched, roll formed, and cut to length by WLGR series guardrail roll forming machine. The finished products are of many features, such as high efficience, high automatization, less labor, and etc. This machine integrates the technologies of cold roll forming, punching, automatic stack, and automatic controlling.

Working flow

Technical parameters

| Material specification | Galvanized steel, cold rolled steel, and carbon steel. | ||

| Thickness | 2.5 mm to 4.0mm. | ||

| Main motor power | 37 kw. | ||

| Dimension | 30m*4.5m*4.5m (length*width*height) | ||

| Feeding width | 500mm. | ||

| Cover width | 311mm. | ||

| Roll forming Speed | 10-15 m/minute. | ||

| Manual Uncoiler | Max. Capacity: 5000kgs. | ||

| Voltage | As customer's request. | ||

| Numbers of stands | 14-16 stands/stations/pairs. | ||

| Roller Material | Roller Material | ||

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 100mm. | ||

| Electric Elements | PLC control console, touch screen and transducer, from Mitsubishi, Japan.Other elements, from famous suppliers of China. | ||

| Cutter blades | Cr12MoV steel with quenched treatment, hardness HRC58~61,wear-resistance, good steel structure, long life. | ||

Components

| No. | Name | Qty |

| 1 | Uncoiler | 1 |

| 2 | Hydraulic Punching | 1 |

| 3 | Main roll forming machine | 1 |

| 4 | Hydraulic Cutting | 1 |

| 5 | PLC Control box | 1 |

| 6 | Hydraulic station | 1 |

| 7 | Output tables | 2 |

Machine pic

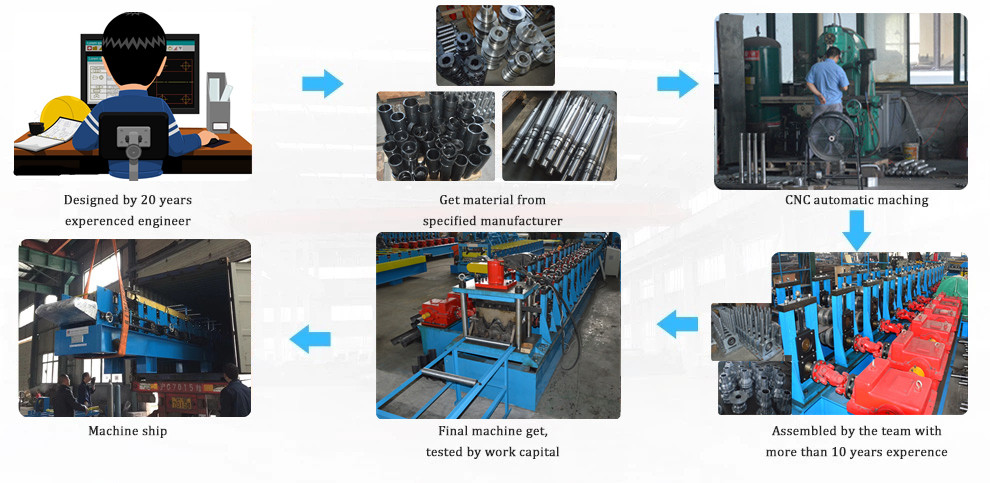

Working process

After-sales service

1.Installation of the plant:

One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100/per day and visa fee, air tickets fee, accommodation and food, necessary communication and insurance, etc.

2.Quality Guarantee:

2 years warranty, Starting from the date of the successful installation and commissioning of the equipment.

Installation

(1) If installation is needed, we will dispatch technician to the buyer's factory abroad to assist regulating the machine with charge free. The buyer should assist Liming to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.

(2) If installation is needed, the buyer shall make the following preparation before arrival of technicians.

a) Position the machine in the buyer's factory.

b) Prepare necessary electric wiring.

c) Prepare material of trial running.

d) Provide labors for assistance and installation during installation.