Jiangyin Dingbo Technology CO., Ltd. |

|

Automatic Double-layer Roof Panel Roll Forming Machine with PLC Control

Product Introduction

The profile drawing

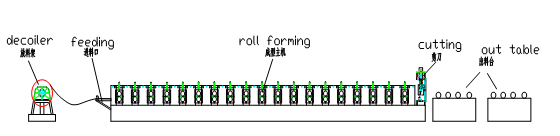

Working flow

Decoiler---feeding---roll forming---hydraulic cut to length---output table

Product Data

| 1. Double layer roof sheets roll former | |

| Main Motor Power: | 5.5kw |

| Raw material | GI steel 0.3-0.8mm |

| Coder | omron |

| Working Hours Per Day | 8 to 16 |

| Roll Station | 14 steps for 840 roof, 16 steps for 900 trapezoidal |

Working Speed | 10m-13m/min |

| Type Of Forming Machine | wall board |

| Shipment Packing | one 40 FT containe |

| Forming Speed | 20mtr./min(Not include shear) |

| Line Direction | Left to Right While Facing Operator Panel |

| Length Tolerance | ±1.5mm |

| Computer Operating Panel | toching screen |

2. Manual decoiler | |

| Capacity | 5ton |

| Feed Width | max 1250mm |

| Expanding Range | 480-520mm |

| 3. passive output table | |

| Valid length | max 4m |

| Capacity | 10ton |

| Max loading height | 100mm |

| Transport | by roller passively |

Photo for refrence

Passive output table

5ton manual decoiler

Certificates

After Service

1.Engineer will give free training lessons to labors in buyer’s factory.

2.The Buyer will buy the round-trip air ticket for Engineer if visa

application is approved. The buyer is also

responsible to bear expenses generated, e.g. visa formalities,

meals, accommodation and

allowance of USD50 per day for engineer.

3.During this guarantee period, we will provide spare parts without

any charge in case of quality

discrepancy caused by us. If the

malfunctions are caused by incorrect operations, we will

provide

the buyer spare parts at cost price.

4.We will charge the buyer cost price of spare parts beyond one

year and provide long-term technical guide.