Jiangyin Dingbo Technology CO., Ltd. |

|

Panasonic PLC Cut To Length Machine With Cutting Automatically

Brief descriptions

Cut-To-Length Lines are purposed for Uncoiling, Leveling and Straighting as well as Cross Cutting metal strip to produce sheets for proper Stacking; every these functions are accomplished by our machines which are designed to cope with an impressive variety of material features ranging from the thinner softer aluminum to the thicker – tougher stainless and high strength carbon steel.

Application:It is suitable for cut the metal coils to sheets/plates.

Advantages:Easy to operate, cut to length quality is high, excellent material utilization, Stepless shearing speed regulation, etc.

Structure:It consist of uncoiler, feeding and positioning, cutting unit, stack, etc.

Applicable Materials:Tinplate, silicon steel, aluminum, copper, stainless steel and galvanized steel, etc.

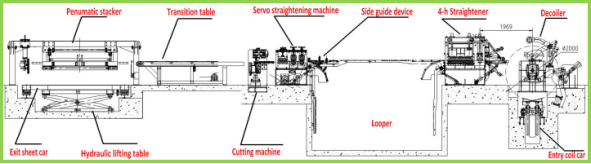

Working flow

Main components

Product list

| Model | Thickness (mm) | Width (mm) | Tolerance (mm) | Speed (m/min) | Weight(t) |

| DBCTL-1x650 | 0.3-1 | 150-650 | ±0.5 | 0-40 | 5,10 |

| DBCTL-2x850 | 0.3-2 | 300-850 | ±0.5 | 0-40 | 5,10 |

| DBCTL-3x1300 | 0.4-3 | 400-1300 | ±0.5 | 0-60 | 10,15 |

| DBCTL-3x1600 | 0.4-3 | 500-1600 | ±0.5 | 0-60 | 15,20 |

| DBCTL-4x1300 | 0.5-4 | 500-1300 | ±0.5 | 0-50 | 15,20 |

| DBCTL-4x1600 | 0.5-4 | 600-1600 | ±0.5 | 0-50 | 15-25 |

| DBCTL-6x1300 | 1-6 | 800-1300 | ±0.5 | 0-40 | 20-25 |

| DBCTL-8x1600 | 2-8 | 800-1600 | ±0.5 | 0-30 | 25-30 |

| DBCTL-10x1950 | 3-10 | 800-1950 | ±0.5 | 0-30 | 30-35 |

If you need detailed parameters of the machine, please tell me the specifications of the sheet you need to process, I will provide you with the data, to give you the technical solutions you need.

Such as:

1,coil .I.D (mm)

2,coil .O.D (mm)

3,MAX coil weight (Ton)

4,main material

5,max coil thickness (mm)

6,max coil width (mm)

7,voltage/ HZ

and so on

Machine picture

Our services

1.Advanced machinery, well trained workers.

2.More than 20 years experience in roll forming machine

industry.

3.Unique designed, good Germany quality,

competitive China price.

4.Full process of roll forming machine solution.

5.Shipment arrangement avaiable.

6.After-sales services for overseas installation and commissioning.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine

overseas to customers’ workshop if

needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in

hurry, we can make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to

the requirement and profile drawing you provide. Our

engineers can offer the best professional solution to our worldwide

clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi

Dong station), half an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful installation and commissioning of the equipments at the Buyer’s Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246