Jiangyin Dingbo Technology CO., Ltd. |

|

Hydraulic Motor 40 M /Min Cutting Speed Steel Coil Slitting Machine Line

Brief introduction

The coil metal slitting line is used for coil with different specifications, through uncoiling--slitting--recoiling to any needed width coil for the application of all kinds of welded pip/tube making machine.

The line is reasonable in layout, easy operation, high level of automation, high productivity which could process coil,silicon coil, stainless coil, colored coil,aluminum coil,galvanize coil or painted coil.The line is broadly applying in metal plate processing industry,like car,container, household application, packing,construction material,etc. this line is composed of coil car,uncoiler,slitting machine, scrap recoiler, tension unit,recoiler and unloading coil car, hydraulic system,ec. This line can be adjusted to do recoiling or dividing work to meet customer's demand.

Flowing chart

From right to left are: Entry coil car→Hydraulic decoiler →Hydraulic press and pinch device→Hydraulic cutter→Looper 1→Side guide device→ Slitter→Scrap winder→Looper 2→Tension stand →Recoielr→Exit coil car

Main components

1. Coil car

2. Decoiler

3. Peeler entry table

4. Straightener.

5. Shearing machine

6. Loop table

7. Coil guide and pinch roll

8. Slitting machine

9. Scrap winder (both sides)

10. Loop table

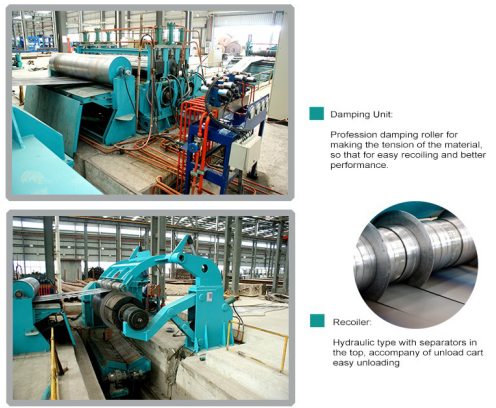

11. Separator and tension table

12. Deflector roll and exit threading table

13. Recoiler

14. Over arm separator in the recoiler.

15. Exit coil car for recoiler

16. Hydraulic system

17. Pneumatic system

18. Electrical control system

The main model you may select

| model | thickness(mm) | width(mm) | number PCS | accuracy(mm) | speed (m/min) | weight(t) |

| DBSL-1x650 | 0.2-1 | 150-650 | 30-8 | ±0.05 | 0-40 | 3,5 |

| DBSL-2x850 | 0.3-2 | 300-850 | 30-8 | ±0.05 | 0-40 | 10,15 |

| DBSL-3x1300 | 0.4-3 | 400-1300 | 30-8 | ±0.05 | 0-120 | 10,15 |

| DBSL-4x1600 | 0.5-4 | 400-1600 | 30-8 | ±0.05 | 0-120 | 15,20 |

| DBSL-5x1600 | 0.6-5 | 500-1600 | 30-6 | ±0.05 | 0-120 | 15,20 |

| DBSL-6x1300 | 1-6 | 600-1300 | 30-6 | ±0.05 | 0-120 | 10,15 |

| DBSL-8x1600 | 2-8 | 600-1600 | 30-6 | ±0.05 | 0-100 | 15,20 |

| DBSL-10x1950 | 3-10 | 800-1950 | 30-6 | ±0.05 | 0-100 | 20,35 |

Such as:

2,coil .O.D (mm)

4,main material

6,max coil width (mm)

and so on

Main machine process

After sale services

1.Engineer will give free training lessons to labors in buyer’s

factory.

2.The Buyer will buy the round-trip air ticket for Engineer if visa

application is approved. The buyer is also responsible to bear

expenses generated, e.g. visa formalities, meals, accommodation and

allowance of USD80 for engineer per day.

3.During this guarantee period, we will provide spare parts without

any charge in case of quality discrepancy caused by us. If the

malfunctions are caused by your incorrect operations, we will

provide the buyer spare parts at cost price.

4.We will charge the buyer cost price of spare parts beyond 2 years

and provide long-term technical guide.

FAQ

1. Does one machine can only produce one size?

Not exactly, it depends on which profile the customer want to

produce.

2.Do you have after-sales technical support?

Yes,we are happy to give advice and also have skilled technicians

available to maintain the machine overseas to customers’ workshop

if needed.

3. You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

4.How long the machine could be made?

Normally speaking, high precision roll forming machine could be

made out with 40 working days.If you need machines in hurry, we can

make it for you less than a month.

5. Do you provide customized?

Sure, we can design the machine according to the requirement and

profile drawing you provide. Our engineers can offer the best

professional solution to our worldwide clients.

6. May we visit your factory?

Sure,Warmly welcome to our factory at any time.

7.How to visit your factory?

By high speed train from Shanghai to East Wuxi (Wuxi Dong station),

half an hour.

8.What's the warranty period?

12 months warranty period, starting from the date of the successful

installation and commissioning of the equipments at the Buyer’s

Installation site.

9.Can we arrange shipment?

Yes, sure, we can arrange shipment for our customers and provide

door-to-door service.

Best Regards

Andy Yang

Director

Mobile/Wechat/Skype:0086 139 2126 2246