Weifang Bright Master Importing and Exporting Co.,Ltd |

|

Verified Suppliers

|

|

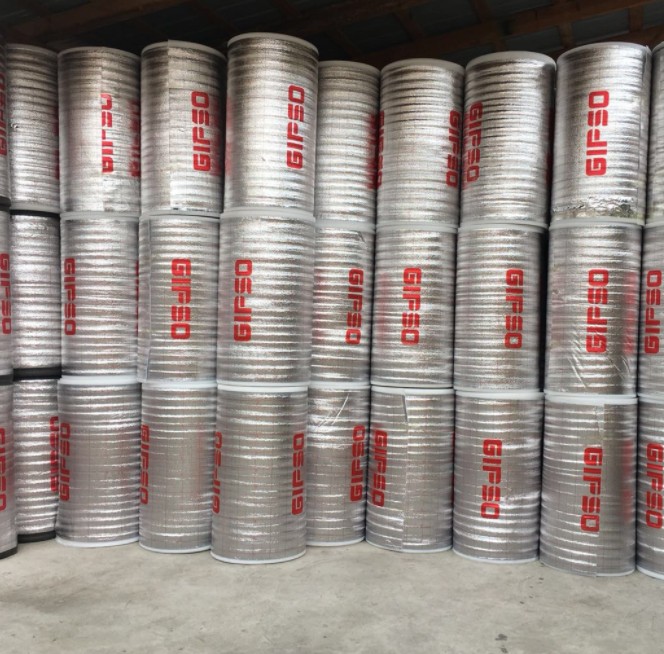

6mic Metallized PET Coated 3mic PE Flexible Printed Film for Packaging

Product structure: PET aluminized film 6um+PE2g

PET aluminized film 7um+PE3g

PET aluminized film 8um+PE4g

PET aluminized film 12um+PE10g

(The material thickness and width can be customized according to the actual needs of customers)

Core inner diameter: 24mm(1”) 76mm(3”) 152mm(6”)

Features of PET Metalized Film

• Metallized PET/BOPP/PVC and LDPE are bonded by extrusion equipment.

• Widely used for laminating with EPE, paper, aluminium foil, woven fabric, non-woven fabric, etc.

• Strong toughness, Not easy to be deformed or broken

• Bright color and not easy to fade

• Good resistant to acids, alkalis and salts corrision

• Different colors are workable.

• Highly glossy, highly printability, puncture resistance, antifriction, chemically resistant, static free, non-toxic, smooth and clear surface, excellent strength food grade, providing protection against moisture, light and gasses, etc.

Features: Aluminized film has good reflection ability to ultraviolet and infrared rays, and achieves the effect of blocking ultraviolet rays. At the same time, it can improve the film's oxygen barrier, moisture barrier, and metallic luster.

Our company has two compound methods:

1. Extrusion compounding method (film compounding) This is the most

commonly used method in compound processing. The extruder is used

to extrude pp, pe, eva ion-type resins into a film, and coat them

with various processing agents The film is compounded, then cooled

and solidified.

2. Dry compounding method This method is to coat the adhesive on the surface of the substrate through a laminating machine and press it on other films with a heated roller to form a compounding method.