Wuhan Jianheng Metal Technology Co., Ltd. |

|

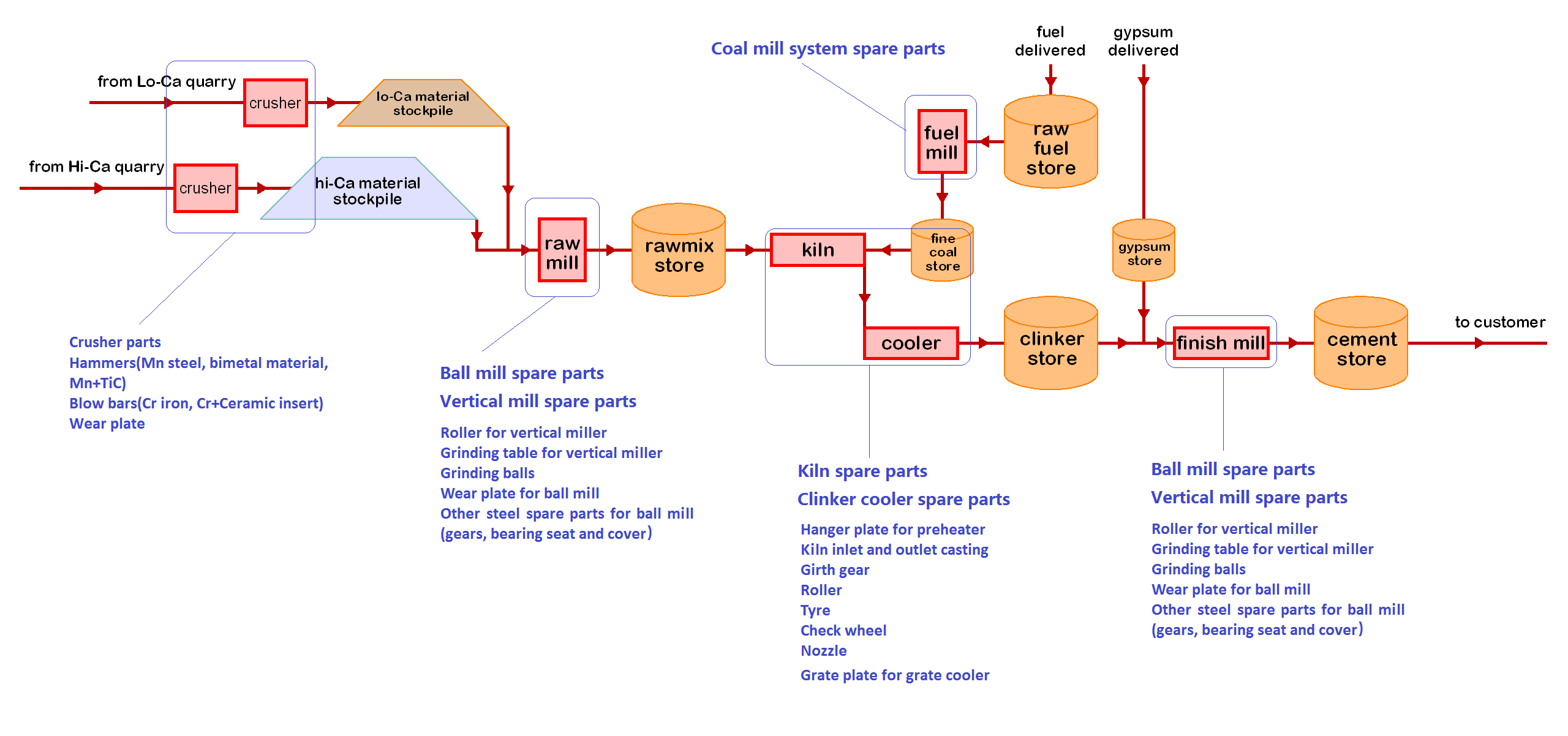

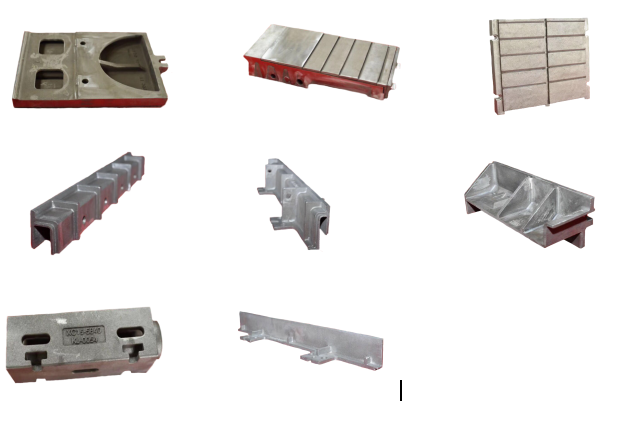

Kiln inlet and out let casting are very important spare parts for kiln in cement prodcution. During kiln working, the spare parts for kiln are under high temperature. The kiln out let and inlet plate are indispensable thermal engineering auxiliary equipment of the rotary kiln system. Under normal production conditions of the kiln system, the clinker temperature is generally between 1300 ℃ and 1400 ℃. The guard plate is washed by high temperature clinker particles, plus Casting materials fall off and other reasons are easily deformed and burned, which leads to serious deformation of the kiln shell.

Material requirement as follow:

| C% | Mn% | Si% | P% | S% | Cr% | Ni% | Mo% |

| 0.3-0.45 | 1-1.5 | 1.0-2.0 | ≤0.03 | ≤0.03 | 24-26 | 19-21 | 0.4-0.6 |

| σb (MPa) | σ0.2 (MPa) | δ5 (%) | ψ (%) | HBW |

| ≥515 | ≥205 | ≥35 | ≥50 | ≤182 |

For cement prodcution line, we also supplying lot of orther castings.

1.Castings for crushers:

Hammers (manganese, bimetal hammers or manganese with insert)

Blow bars (with or without ceramic)

2.Castings for miller:

Roller for vertical miller

Grinding table for vertical miller

Grinding balls

Wear plate for ball mill

Other steel spare parts for ball mill (gears, bearing seat and

cover)

3.Castings for preheater:

Hanger plate

4.Castings for kiln

Kiln inlet and outlet casting

Girth gear

Roller

Tyre

Check wheel

Nozzle

5.Grate cooler

Grate plate

We are supplying many different kind of heat resistant steel castings to our customers and we use both investment casting process and sand casting process for different size or different structure casting. For suitable castings, we also choose lost foam process which have better cost and quality performance.

There have lot of different specifications for such castings, usually we produce according to customers drawings and specific requirement, following are the common materials which we usually supply: ZG35Cr24Ni7SiNRe, ZG40Cr25Ni20Si2, 1Cr18Ni9, ZGCr25Ni35Nb, ZGCr28Ni48W5 HK40, HT, HU, HH, 22H, 304, super 22H, HP-Nb, More1, More2, 1.4848, 1.4855, 1.4852, 2.4879, 1.4460, 1.4462, S32205, S32750, etc.

Our products are been widely use in cement plants, electric generate plant, melting industry, and other industries. In recent years, there are more and more professional municipal waste incineration stations, and we have developed a lot of heat-resistant casting products specially supplied to such factories.