Xiamen METS Industry & Trade Co., Ltd |

|

Verified Suppliers

|

|

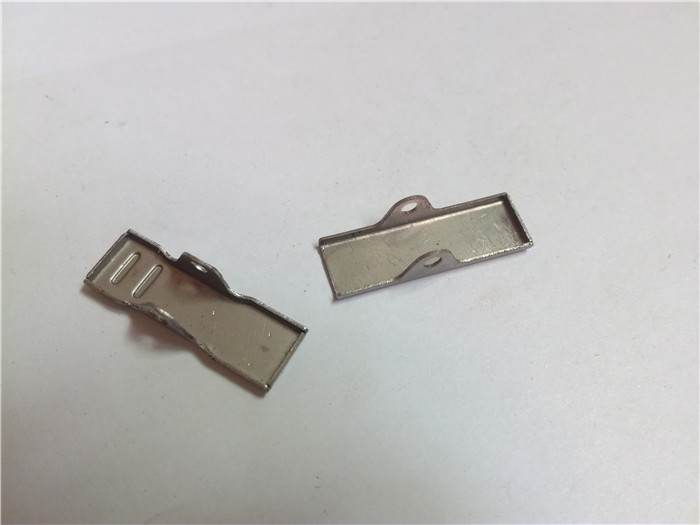

Hanger Clips Metal Bending Rivet Press Dies Sheet Betal Bracket Stamping

Metal Stamping Die Capability

· Die Insert Tolerence: +/-0.008mm

· Stamping Speed: 1000SPM/min

· Tooling Life: 50-300 million times

METS Precision-Tool uses a variety of 2D and 3D cad/cam Software to develop, design, and plan the layout of our dies. (see below for the full software list & details). We have the resources to build a die for any application. When high volumes of production are expected, we can build a dependable tool with longevity in mind. We can also produce low-cost tools for prototyping and sampling applications. Die protection is always on our mind, and DACO Precision-Tool can build in sensors that will help prevent costly damage to the die.

METS will continue to pursue the business philosophy of technological innovation, exquisite quality and service-oriented, and are committed to providing more perfect solutions for users'' needs.

We place great importance to use efficient tools, we widely used structure design software, automated software engineering and visual simulation software to significantly reduce design issues, avoid repeated modifications, shorten delivery time for cost saving, high efficiency and creating value for customers.

Introduce advanced management methods, constantly improve the comprehensive quality of employees, and make enterprise management standardized and scientific, so as to adapt to the development of society. Enable enterprises to develop faster, higher and more effective.

Tool&Die Profile

| Part thickness | 0.5-2mm | ||

| Spare parts for Dies and insets | Accept JIS, AISI, DIN standard. From MISUMI, PUNCH, Mold Master, LKM to DANLY, FIBRO, Dyton press and so on | ||

| Die type | Progressive deep drawing die ,progressive tool, stamping forming die,compound die, ect. | ||

| Die material | YG15,YG20,DC53, SKH-9, SKH51, SKD11,D2, | ||

| Die use | Auto,Building,Capital Equipment,Energy,instrumention,Medical Device,Telecommunications | ||

| Part material | Aluminum,Plastic,Copper,Brass,Galvinized,Steel,Stainless steel | ||

| Machinery Equipment | Milling, Grinding, CNC, EDM, WEDM, Forming Machine, Precision flat milling,Punching machine, | ||

| Die precision | High precision machining, minimum 0.003mm | ||

| Trial out press | 25~180T | ||

Meterial | Titanium Alloy, Brass, Bronze, Copper, Aluminum, Mild Steel, Stainless Steel, A366, Alloy, Carbon steel, ABS, PC, PEEK, PPS, PPS GF40, PPS GF30, POM, PET and so on. | ||

How to start a new mould business?

| 1. Quote | According to samples/picture/design, 2/3 D drawing and specification |

| ↓ | |

| 2. Discussion | Mould core/base material, cavity number, runner type, price, payment, etc |

| ↓ | |

| 3.PI | Approval for all terms |

| ↓ | |

| 4. Deposit | 50% by T/T |

| ↓ | |

| 5. Product Design | Our engineer will check product drawing, and pick up the unreasonable terms |

| ↓ | |

| 6. Mould Design | Our engineer will do DFM and send PPT to customers for approval |

| ↓ | |

| 7. Mould making | We start to make mould after customers confirmed the drawing |

| ↓ | |

| 8.Mold Testing | We will express trial samples to customers by DHL for confirmation |

| ↓ | |

| 9. Mould repair | We will modify the mould according to customer’s feedback |

| ↓ | |

| 10. Mould approval | Express trial samples by DHL again till products approval |

| ↓ | |

| 11. Balance payment | 50% by T/T before delivery |

| ↓ | |

| 12. Delivery | Delivery by sea or air, all documents as customer required |

We accept your any request on shipment.By air, by sea,and by Express are acceptable.

| By Express | By Air | By Sea | |

| West Europe | 3-5 days | 4-6 days | 22-30days |

| USA &Canada | 3-4days | 5-6 days | 16-27days |

| South Asia | 3-5 days | 3-7 days | 12-20 days |

| Japan&South Korea | 2-3 days | 3-4 days | 10-13 days |

| Russia | -------- | --------- | 30-40 days |

Commom packing are:

1, Carton

2, Pearl cotton + carton

3, Bubble bag kraft paper + carton

4, Wrapping film + wooden box

5, Wrapping film + pearl cotton + wooden box

6, Wrapping film + pearl cotton + wooden box + wooden pallet

our advantage

1, We have our own factory, and 80% of our employees have been working for more than 10 years.

Why choose us?

1) Best quality, resonable price

2) Main market is USA,quality is large.

3) We have technicist to open metal moulds at very fast speed.

4) We can offer one-stop solution and best services

5) We haveadvanced equipments which be examined at regular intervals.

6) Prompt delivery

7) The mainest reason is we are real manufacture with very competitive price ,direct business!

Q:Where is your company located? Can we visit it?

---A:We are inXiamen, China. You are welcome to visit us at any time.

Q:Where can I get product & price information?

---A:Send us inquiry e-mail, we will contact you as we receive your

mail.

Q:How can we make sure the quality from your company?

---A: We have our professional team and we have initial part

inspection, batch production inspection and finished products

inspection. We will test products quality before delivery.

Q:What's the package?

---A:In order to keep goods safe, The package will be customized

according to the products.

Q:How do you make our business long-term and good relationship?

---A:1. We keep good quality and competitive price to ensure our

customers benefit.

2. We respect every customer as our friend and we sincerely do

business and make friends with them, no matter where they come

from.

| Warm tips |

| 1.All our metal stamping parts are made to order.The pictures showed on the website are for your reference and to show you about our production capability . |

| 2.If you are interested in our products. Please kindly send us your brief inquiry with drawings&requirement by email.Our professional sales team will get back to you as soon as possible. |