Guangdong Huabao Xingye Automation Technology Co., Ltd |

|

Verified Suppliers

|

|

Multipurpose Metal CNC Turned Components Tolerance 0.02mm P20 Material

Processing & Inspection Machine List.pdf

One of the typical parts often encountered in hardware accessories.

Shaft parts are one of the typical parts often encountered in

hardware accessories. It is mainly used to support transmission

parts, transmit torque and bear loads. According to the structure

of shaft parts, which can be divided into three types: optical

shaft, stepped shaft and special-shaped shaft; or divided into

solid shaft, hollow shaft, etc.

In industrial products, shaft parts are suitable for one or more

CNC machined parts maintenance operations. They are used in

machines to support transmission parts such as gears and pulleys to

transmit torque or motion. Shaft parts are rotating body parts,

whose length is greater than the diameter, and are generally

composed of the outer cylindrical surface, conical surface, inner

hole, thread and corresponding end surface of the concentric shaft.

| Manufacturer | Hua Bao |

| Product Name | Shaft Part Precision Turned Parts |

| Industry Standards | DIN, JIS, AISI, GB |

| Design Tools | UG, ProE, Auto CAD, Solidworks, etc |

| Surface Finishing | Nickel Plated |

| Quality Inspection Instrument | Micrometer Calipers, Concentricity Measuring Instrument |

| Processing Machines | NC Lathe Machine |

| Other Service | ODM and OEM, Customized Specification, One to One Communication |

| Order Process | Customer inquiries (provide 2D or 3D drawing) →Hua Bao provides quotes and lead time→ Orders released by customer→ 50% advanced payment→ Arrange production →QC pass→Packing and shipping after receiving balance payment. |

Hua Bao has a group of high-precision NC Lathes and turning-milling compound machines imported from Japan and Taiwan. Our NC Lathes have been highly appreciated by our customers for their stable quality and efficient productivity

| Hua Bao CNC Machining Centers | Hau Bao NC Lathes | ||||

| Brands | MAKINO, DHLIH, NXV, JINGDIAO | TAKISAWA, HARDING, MAZAK | |||

| Accuracy Class | ±10.002mm | ±0.005mm | |||

| Total Number | 17 | 14 | |||

| Features | 1. High accuracy on processing | 1. High processing stability | |||

| 2. The largest working width can reach 1020mm | 2. Has milling function | ||||

1. Best product quality and most competitive price.

2. Experienced technicians are in production.

3. High-end processing machines and inspection instruments.

4. Customized designs and production.

5. Excellent pre-sale and after-sale service.

Hua Bao is a professional manufacturer of machined parts and mold parts, established in 2009 with a total of 120 employees. We have established machined parts and mold parts two factories to meet the needs of various industries and product diversification in Shenzhen and Dongguan, China, respectively. Our products are exported to North America, Europe, Southeast Asia and other parts of the world. Meanwhile, our products are involved in various fields such as automation equipment industry, mold industry, automobile industry, medical industry, home appliance, military industry, communication industry and cosmetics industry, etc.

Business Philosophy:

1. Quality is the soul of an enterprise.

2. Competitive price is our advantage.

3. Enthusiastic service is our tenet.

4. Innovation is our eternal pursuit

Quality Objectives:

1. Sample acceptance rate reaches 100%.

2. The qualified rate of finished products reaches 100%

3. Punctual delivery rate reaches 100%

Our Mission:

1.Strengthen management and continuously enhance satisfaction for customers, investors, suppliers and employees.

2. Enhance innovation capacity and contribute to sustainable development.

1. Provide the detailed production schedule for each order.

2. Offering production status with video and photos for each component.

3. Manufacture the parts base on customers' drawings to meet the quality requirements and industry standard.

4. Over 99% orders can meet the lead time requirement.

5. Respond to the enquiry within 24 hours and offer the quotation within 48 hours.

6. Using the first-rank raw materials which also can be traced.

7. Provide the most competitive price with the high quality and service standard.

8. The most reasonable packing scheme for all products.

FAQ:

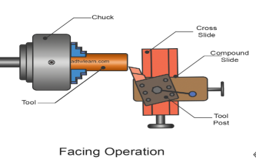

A: What is Turning? Turning is a machining process used to make cylindrical parts, where the cutting tool moves in a linear fashion while the workpiece rotates. Commonly performed with a lathe, turning reduces the diameter of a workpiece, typically to a specified dimension, and produces a smooth part finish.

Q2: What is step turning process?

A: Step turning is a turning process in which series of steps having different diameters is produced with the lathe machine. Procedure. Fix the cylindrical workpiece into the chuck and secure it properly.

Q3: What are the advantages of turning?

A: Advantages of the turning process:

All materials are compatible.

Very good tolerance.

Short lead time.

No high skilled operator required.

The material removal rate is flexible.

Q4: What are the three main movements of turning operations?

A: Therefore, there are three basic movements: Rotation movement: The part to be mechanized is placed on a rotating shaft, making it rotates around itself. Advanced movement: The tool moves parallel to the piece, making a straight movement that defines the machining contour.