Anping County Anhesheng Hardware Mesh Products Co., Ltd. |

The Fiber Bed Mist Eliminator has proven to be ideal for sulfuric, nitric, and thermal phosphoric acid plants; chlorine and other chemical plants; pulp and paper plants; textile plants; asphalt saturation towers; food processing; forming. Applications containing fluoride, high pH or steam can use special carbon fibers.

Structurally the mist eliminators consist of two coaxial cylindrical meshes welded to bottom and inlet flange branch. Frame material: stainless steel AISI 316L. The area between meshes is filled with fiber, the element bottom is equipped with a tube merged into water seal barrel out of which the trapped liquid flows to the unit case. Mist eliminators are attached to the base plate of the column through P.T.F.E. laying with the help of pins and nuts. From 1 to 50-70 elements may be arranged within one apparatus case depending on the unit performance capability. In existing sulfuric acid plants such elements are often installed in a separate case, and in new shops – in upper part of absorbers (with performance capability of up to 170 thousand м3/ч).

- low-velocity (ʊ ≤ 0,2 m/sec), equipped with fibers 5-20 mcm in diameter and intended for trapping of submicron particles with the help of Browning diffusion and catching effect; their efficiency increases as the filtration velocity, particles size and fiber diameter decrease;

- high-velocity (ʊ ≤ 0,5 + 1,2 m/sec) with the layer of coarse fibers 20-100 mcm in diameter that are used for separation of gas from particles 1 mcm and larger using the mechanism of inertial precipitation the efficiency of which increases with the increase of particles size and filtration velocity up to a specific (critical) point (usually 1-2.5 m/sec) at which the secondary carryover of trapped liquid drops takes place.

| Name | Conditional name | |||

| Low-speed high-efficiency | High-performance | High Speed | Mist eliminator | |

| Speed of filtration, m/s | 0,05 - 0,2 | 1,1 - 1,3 | 2 - 2,5 | 2,5 |

| Cleaning efficiency of particle,%: dc = 3 mcm dc = 1 ÷ 3 mcm dc ≤ 1 mcm |

100 |

100 |

100 |

100 |

| Resistance, kPa | 1 - 5,0 | 2 - 2,5 | 1,5 - 2,0 | 0,25 - 0,5 |

| Form of elements | Cylinder | Cylinder | Rectangular | Rectangular |

| Dimensions, mm: diameter (width) height |

216; 450; 605; |

650 |

470 |

470 |

| Thickness, mm | 50 - 60 | 50 - 60 | 25 - 30 | 25 - 30 |

| Fiber diameter, mcm | 6 - 15 | 18 - 20 | 10 - 30 | 30 - 80 |

Fiber bed mist eliminators can be used in a variety of applications including cold heading machines, EDM machines, hot forging, and parts washers. The unit exceeds OSHA standards and is able to comply even as OSHA updates standards.

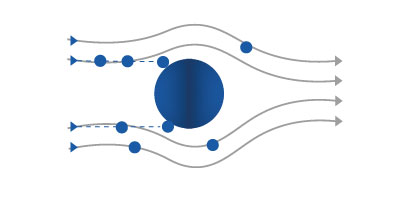

Particles of 3 microns or larger are collected when their moment

(kinetic energy) prevents them from following the gas streamlines

around a fiber. The moment the particle causes it to remain on its

path reaching the fiber where it is captured.

Particles of 3 microns or larger are collected when their moment

(kinetic energy) prevents them from following the gas streamlines

around a fiber. The moment the particle causes it to remain on its

path reaching the fiber where it is captured.

Since momentum is a function of the particle's mass and velocity,

it follows that large drops will be collected more efficiently than

small drops traveling at the same speed. This type of mechanism is

extremely dependent on the particle inertia and the viscosity of

the gas.

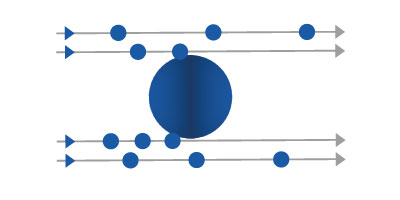

Some particles follow the path

of the gas, but due to their diameter, they end up“touching" the

fibers of the bed, where they are collected.

of the gas, but due to their diameter, they end up“touching" the

fibers of the bed, where they are collected.

Mechanisms are little dependent on inertia, particle, and gas viscosity.

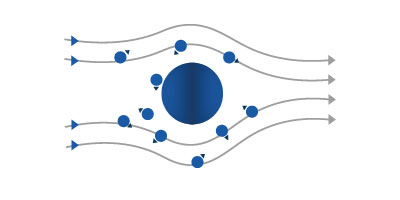

Sub-chromic particles are collected when their moment (kinetic

energy) prevents them from following the gas streamlines around a

fiber.

Sub-chromic particles are collected when their moment (kinetic

energy) prevents them from following the gas streamlines around a

fiber.

The moment of the particle causes it to remain on its path reaching

the fiber where it is captured.

Since momentum is a function of the particle's mass and velocity,

it follows that large drops will be collected more efficiently than

small

drops traveling at the same speed. This type of mechanism is

extremely dependent on the particle inertia and the viscosity of

the gas.

Anping County Hardware Mesh Products Co., Ltd. is located in Anping

County, Hebei Province, known as the "Hometown of Chinese Wire

Mesh". The company is a dedicated manufacturer of wire mesh

demisters. The company has more than 90 sets of knitted mesh

equipment.The wire mesh demister is the main product of our

company. Most of our employees are operation, maintenance, and

installation personnel with practical experience, who can provide

customers with the required engineering consultation and

installation of tank filtration. solution.Nearly 20 years of

experience in the production of mist eliminator mats, knitted wire

mesh, and other packaging materials.

We have ISO9001 certification and a strict quality control system

in the QC department of the enterprise.

We claim that all mist eliminator pads our customers receive are

qualified and perform perfectly. We have different specifications.

The filtration fineness can reach 3μm~5μm. In addition to standard

and popular sizes, we can also customize specific applications

according to customer needs.

During the company's development, through continuous on-the-spot

inspections, personal exchanges and cooperation with customers, and

comprehensive discounts and technical support, we have won strong

customer support and praise.

The company's performance has maintained an annual output value

growth rate of 30-40. Our employees pursue the policy of

"enterprising, truth-seeking, rigorous and united", continue to

develop and innovate, take technology as the core, and

wholeheartedly provide you with cost-effective products,

high-quality engineering design, and services.