Ningbo WeiWo Electromechanical Tech Co.,Ltd. |

|

OEM Brass Stainless Steel Aluminum Turning Service CNC Machining Parts

Specification:

| Quality Assurance | ISO9001:2008 Certified |

| Machining Equipment | CNC Machining Center /Composite CNC Machine / CNC Lathes / Grinding Machines / Milling Machines / Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines / etc. |

| Materials | Aluminum Alloy: |

| 6061/ 6063 / 7075 /5052 ADC12/518 etc. | |

| Brass Alloy: | |

| H59 / H62 / H64/ 3602 / 2604 / etc. | |

| Stainless Steel Alloy: | |

| 316L / 304 / 316 / 412 / etc. | |

| Steel Alloy: | |

| Carbon Steel / Die Steel / Spring Steel etc. | |

| Other Special Materials: | |

| Titanium/ Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK etc. | |

| We handle many other type of materials. Please contact us if your required material is not listed above. | |

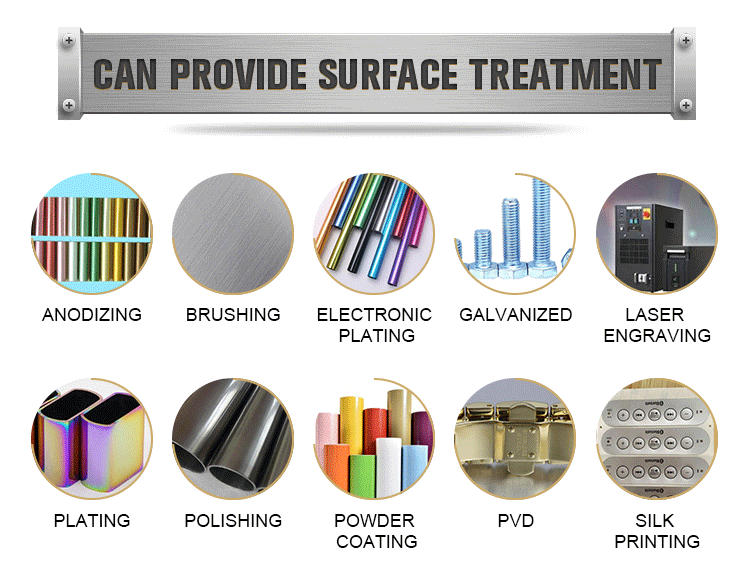

| Surface Treatment | Plating, Brushing,Polishing,Sandblasting,Anodizing,Pickling&Passivation, Vibration,PVD, Nickel Plating,tinting etc. |

| Inspection | three-coordinate measuring machine /Mitutoyo Tool Microscope can measure up to 300mmX x 175mmY x 220mmZ |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,IGS , STP etc. |

Our CNC maching services:

CNC equipments we have as below:

CNC Machining Center /Composite CNC Machine / CNC Lathes / Grinding

Machines / Milling Machines / Wire-cuts / Laser Cuts / CNC ,

Shearing Machines / CNC Bending Machines / etc.

Various materails as below:

Aluminum Alloy: 6061/ 6063 / 7075 /5052 ADC12/518 etc.

Brass Alloy: H59 / H62 / H64/ 3602 / 2604 / etc.

Stainless Steel Alloy: 316L / 304 / 316 / 412 /1.4435 etc.

Steel Alloy: AISI 1020, Carbon Steel / Die Steel / Spring Steel ,

(15Cr,20Cr,42CrMo) etc.

Surface treatment:

we can do anodizing,blackening,electroplating,painting,powder coating,passivate,carburize etc. polished,mirror polished,brushed, sandblasted, heat treatment etc.silver/tin/chromium/oxide blace (or customed)

Description:

We are a professional custom metal parts manufacturer in machining parts with many years. We specialize in machining die and mould design, manufacturing and processing with many years. We can offer the most cost-effective way to the project according to customer's order quantity, we can use laser cutting, CNC punching and CNC bending automatic production, these products can be used in different areas such as industry and automotive spare parts.

Finish for machining parts

Different fittings different finishs request, suitable

finish can make washer keep nice surface and anti-rust.

1) Zinc

this is the most popular treatment, the usual color cover black,

silver, yellow and white or others

2) Nickel

this is more good finish than zinc and is sole color, many parts

are plated also in this finish

3) Oxidization

this finish is used for part stainless steel pieces, and the most

aluminum parts

4) Polish

the parts will be more bright after polished, especially for

stainless steel parts

5) Paint

the color of paint is more abundant, it is more paint in different

colors

6) bronze

this finish is very few used just for some special pieces

|

Equipment:

| Equipment | Laser Cutting Machines | CNC Flame cutting machine |

| CNC Shearing Machines | CNC Turret Punching Machines | |

| Air Pressure Squeeze Riveter | Welding Robot | |

| Argon Arc Welding Machine | Swinging Arm Spot-welding Machine | |

| Horizontal Metal Band Sawing Machine | Aluminum Profile Super Efficient Automatic End Milling | |

| CNC bending machine | single column vertical lathe | |

| Radial drilling machine | EDM CNC wire cutting machine | |

| Metal band sawing machine | Open type fixed table press ( 40T-400T) |

QUALITY CONTROL

1) Checking the raw materials after all materials reach our

factory------- Incoming quality control ( IQC)

2) Checking the all details before the production line operated.

3) Have full inspection and routing inspection during mass

production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality

control(FQC)&Outgoing quality control(OQC)

Our Factory Production Process

1) First Our Designer Making the drawing for OEM products CAD 3D file, such as STP, DWG,PRO, SolidWords, customer also can send the drawing to let us confirm the sizes datas.

2)Our skill workers will use the CNC machine to make the CNC

samples maching parts to let the customer test well, then we will

contiue to do mass production for the customer

3) Our Engineer will do the test on the samples , after test well, we will delivery the samples to the customer, then our customer will test it and any issue, will reply us

Our factory using the stainless steel material to produce the CNC maching parts

|  |

Our factory using the brass material to produce the CNC maching parts

|  |

Our factory using the Aluminum material to produce the CNC maching parts

|  |

Application Area

(1)Auto Area Application

Engine: Cylinder Heads,Turbochargers,Connecting Rods,

Crankshafts,Pistons,Bearing Caps

Front suspension: Steering Knuckles,CV Joints, Brake Calipers,Brake

Discs,Real differential:Differential Housings,Gears,Axle Shafts

(2)Energy Application

Oil and Gas: Drill Pipes and Casting,Pipe Control Valves,Wellhead

Equipment,Mud Pumps, Frac Pumps and Frac Tools

Power Generation: Rotor Shafts and

Discs,Castings,Impellers,Generator Shafts,Blades and Blade Roots

(3)Consumer Electronics: Smart Phones,Semiconductors,Laptop computers,Vacuum Chambers,Monitors,Desk Top Computers,Large Flat Panel Displays (sports and music events)

Competitive Advantage:

Safety:

100% inspection before shipping

Cost:

Factory price to save your cost

Quality:

Quality of each part can be traced from material to delivery

Choice:

More than ten kinds of colors processing can be provided

Picture show:

|