Wuxi MAZS Machinery Science & Technology Co.,Ltd. |

|

Verified Suppliers

|

|

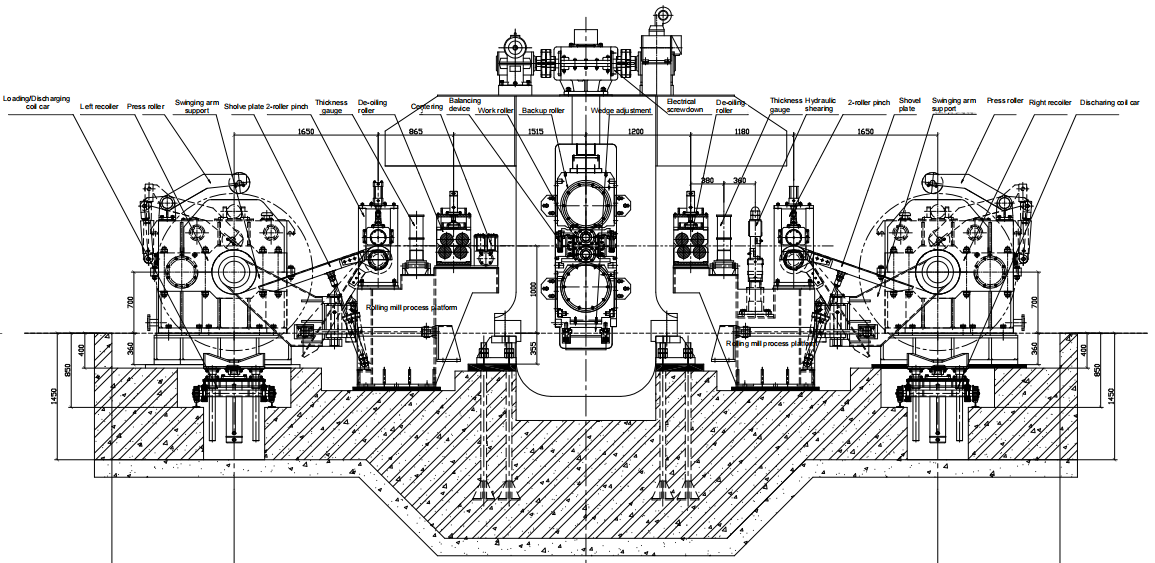

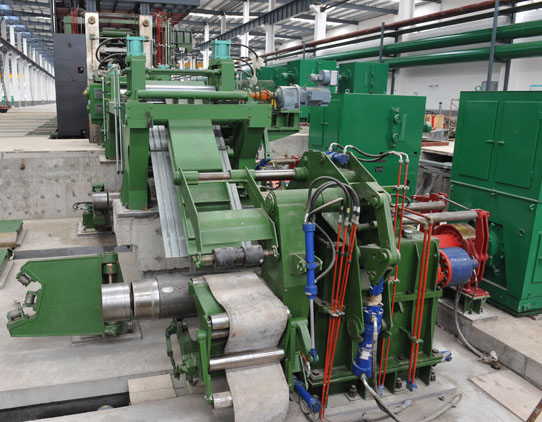

MA Φ385×1450/Φ450×1400/Φ1250×1350mm 6-Hi Stainless Steel Coil Reversing Cold Rolling Mill

1. Product description

A reversing mill is a rolling mill in which the workpiece is passed forward and backward through a pair of rolls. The reversing mill is so named because the steel runs back and forth between the rollers, reducing the thickness incrementally with each pass. A reversing mill can be used to reduce material to gauge.

2. Introduction

This rolling mill is 6-hi rolling mill. Drive middle roller, hydraulic AGC press-down.

3. Process flow: (for reference)

Decoiler with coil loading car → Coil end straightener → Left recoiler with coil discharging car → Work platform before rolling mill → 6-hi cold rolling mill → Work platform after rolling mill → Right recoiler with coil discharging car

4. Characteristics:

5. Technical Parameters (options):

| Type | Φ150/Φ175/Φ460×450 | Φ150/Φ175/Φ500×500 | Φ165/Φ200/Φ630×650 | Φ165/Φ250/Φ680×800 | ||||

| Input thickness(mm) | 1.0-2.5 | 1.0-2.5 | 1.0-3.5 | 1.0-3.5 | ||||

| Finished thickness(mm) | 0.15-1.2 | 0.15-1.5 | 0.18-2.0 | 0.2-2.0 | ||||

| Coil (mm) | 250-350 | 300-400 | 400-500 | 550-700 | ||||

| Drive | Work roller | Work roller | Work roller | Work roller | ||||

| Rolling force(KN) | 2800 | 3500 | 5000 | 5500 | ||||

| Press-down | motor | hydraulic | motor | hydraulic | motor | hydraulic | motor | hydraulic |

| Rolling speed(m/s) | 3.5 | 4-6.5 | 3.5 | 4-8 | 3.5 | 4-5 | 3.5 | 4-5 |

| Rolling material | Normal carbon steel | Normal carbon steel | Stainless steel or carbon steel | Stainless steel | ||||

| Type | Φ170/Φ300/Φ800×900 | Φ300/Φ370/Φ950×1050 | Φ330/Φ370/Φ1050×1250 | Φ400/Φ450/Φ1250×1450 | |

| Input thickness(mm) | 2.0-4.0 | 2.0-4.0 | 2.0-4.0 | 2.0-4.0 | |

| Finished thickness(mm) | 0.2-2.0 | 0.2-2.0 | 0.2-2.0 | 0.2-2.0 | |

| Coil (mm) | 700-900 | 650-950 | 700-1100 | 900-1250 | |

| Drive | Work roller | Work roller | Work roller | Work roller | |

| Rolling force(KN) | 6500 | 10000 | 12000 | 15000 | |

| Press-down | motor | hydraulic | hydraulic | hydraulic | hydraulic |

| Rolling speed(m/s) | 3.5 | 4-5 | 10 | 8-12 | 8-16 |

| Rolling material | carbon steel or stainless steel | Normal carbon steel | Normal carbon steel | Normal carbon steel | |

Note: The above parameters are for reference only, it could be manufactured according to customer's requirements.

6. Packaging

Machine will be fixed inside container by steel wire and special PET strap, in order to make sure all parts will not move during transportation and avoid any kinds of damage of machine and container.

7. Warranty term: 12 months (excluding easy-broken parts)

8. Our service and features:

8.1 Design: We have a matured technical team with rich experience to develop

and deisng the machines according to customer's demand and

requirements.

8.2 This is a very perfect and durable equipment. We have more than 10

years experiences.

8.3 This kind of machine has the best quality and the best price. It has accurate measurement and easy operating.

8.4 We provide technical support (both before, during and after sales),

production, installation, commissioning and maintenance service to

all customers.

8.5 Our product has been exported to many regions and won high

reputation because of the high quality and reasonable price.