Foshan Maxsteel Trading Limited |

|

Verified Suppliers

|

|

A sandblast handrail, also known as sandblasted handrail or sandblasted railing, refers to a type of surface treatment applied to a handrail using a sandblasting technique.

Sandblasting is a process that involves forcibly propelling fine particles, such as sand or abrasive materials, at high speed onto a surface to remove contaminants, smooth rough surfaces, or create a desired texture or appearance. In the case of a handrail, sandblasting can be used to create a unique and textured finish.

To achieve a sandblast handrail, the handrail is typically made from a material such as metal (e.g., steel, aluminum, stainless steel) or wood. The handrail is first prepared by cleaning and preparing the surface to remove any dirt, rust, or previous coatings. Then, a sandblasting machine or apparatus is used to direct a stream of abrasive particles onto the handrail's surface. The force of the particles hitting the surface creates a textured or etched effect.

The specific pattern or appearance of the sandblast finish can vary depending on factors such as the type of abrasive material used, the pressure applied, and the distance and angle of the sandblasting nozzle to the handrail. It can range from a subtle, fine texture to a more pronounced and rougher surface.

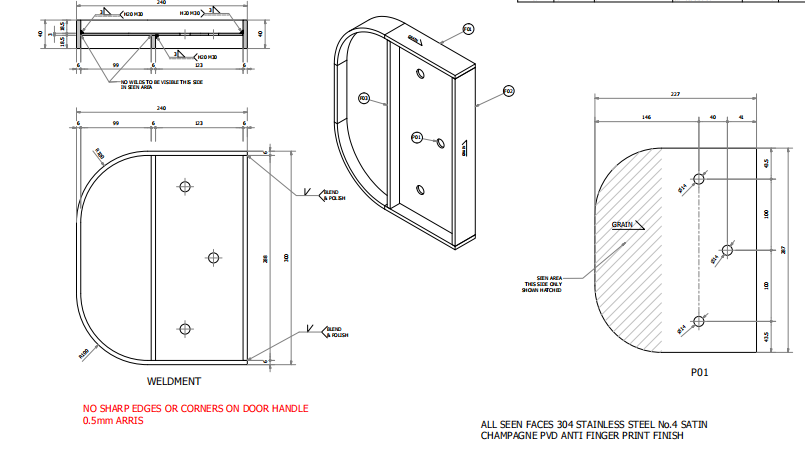

2.Product Parameters

| Material: | High quality stainless steel |

| Finish: | Polished into SSS/PSS/PVD |

| Application: | Suitable for glass fencing, handrail staircase or glass railing. |

| Feature: | Made by stainless steel 201/304/316, wood, crystal |

| Balustrade Height 850,870,950,1050,1200mm | |

| Side steel thickness: 6,8,10,12mm | |

| Clamp toughened glass with 8~12mm thickness | |

| with top round or flat saddle | |

| with square or round plate and cover | |

| Packing: | 1.Each type of product is packed in separate inner boxes. |

| 2.Each outer box will be properly closed and packed to eliminate damages and theft during transportation |

QUALIFIED LEADS AND POWERFUL INSIGHTS WHEN MANUFAC TURING

-Delivering World Class Solutions - We are Standard setter

-Accelerate the Confirmed of shop drawing - Drawing -deepening designer team in train

-Precise engineering save your time - Meet the requirement of Site Operation

3.Product Package