Customized Solid Small Cylindrical Brass Stud, Decorative Brass

Fastener

A solid brass stud typically refers to

a small cylindrical or disc-shaped fastener or embellishment made

entirely of solid brass. It is commonly used in various

applications, including fashion accessories, leathercraft,

upholstery, and woodworking. Here are some key points about solid

brass studs:

Material: Solid brass studs are made from

brass, an alloy primarily composed of copper and zinc. Brass is

chosen for its durability, corrosion resistance, and attractive

golden appearance. It is known for its strength and ability to

withstand wear and tear.

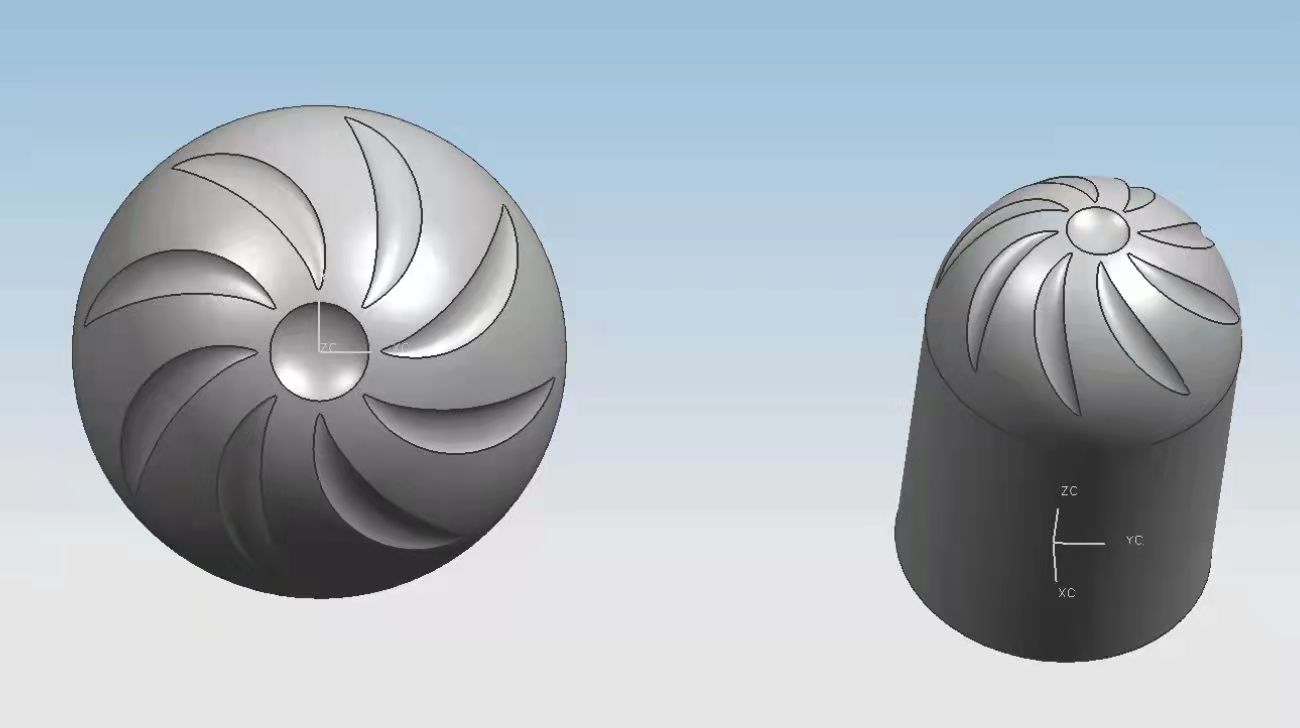

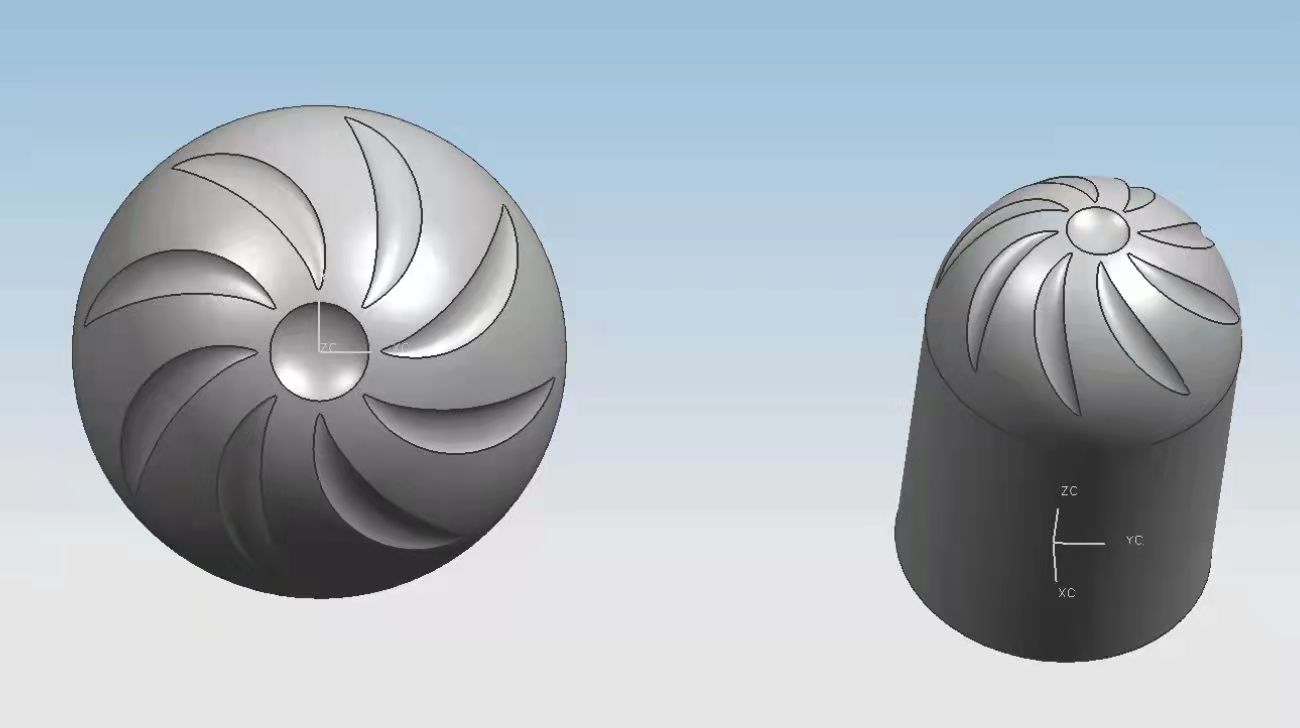

1,Design and Types: Solid brass studs come in various designs and

types to suit different purposes. Some common types include:

2,Flat-Head Studs: These have a flat top surface and are often used

for attaching leather or fabric to furniture, belts, bags, or

clothing items.

3,Dome-Head Studs: These have a rounded or domed top surface,

providing a decorative element. They are often used in

leathercraft, upholstery, or fashion accessories.

4,Screw-Back Studs: These have a threaded screw-like post at the

back, allowing them to be securely screwed into a material or

surface.

5,Pronged Studs: These have sharp prongs or spikes at the back,

which can be pressed into the material to hold the stud in place.

3.Working Procedure

-We get your CAD Design or your practical samples

-We will design the thenical craft of the mould

-Make Aluminum Mould and check the design details

-Brass Sample come out

-Go to Polishing

-Electro plating to get the antique style

- Advanced Production Equipment

- Strict Quality Control

- Skillful technology-Complete Surface

Processing Technology

- Multiply way of manufacturing-Produce

According to Customer's Requirement

- Completely Industrial Production

Process

- Large-scale Production Capacity-40000

Sqm Own Factory

- Provide SGS Test Report-Affirmed by

Global Customers

- Reliable & Trusted Since 1994(26

years history)