BLOOM(suzhou) Materials Co.,Ltd |

|

Verified Suppliers

|

|

1 . Description

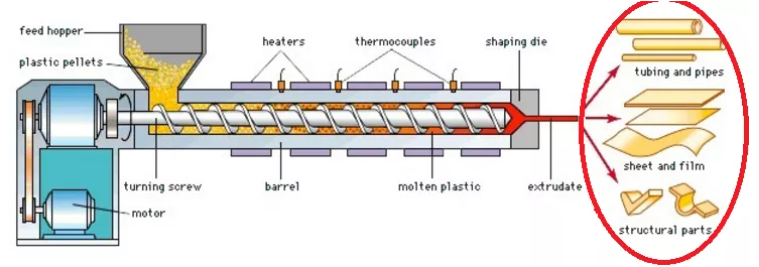

Since the food extruder and the pharmaceutical extruder are both powdery solid materials or granular solid materials to be fed, compared with the extrusion of ordinary polymer materials, they bear more severe shear wear and matching wear; and because these materials often still contain a certain amount of water or even a certain amount of salt, the barrel and screw are in alkaline corrosion conditions. Therefore, the barrel and screw of food extruder and pharmaceutical extruder need to be resistant to both wear and corrosion specially. Martensitic stainless steel with high corrosion resistance and high hardness has become our first choice for manufacturing the food barrel and screw.

The hardness of the 440C series stainless steel after quenching can reach HRC58~62, and it has excellent wear and corrosion resistance. It can be suitable for manufacturing that needs to withstand high wear resistance, high load, high torque, and under the action of acid and salt corrosive media, can be made the barrel, screw and die for the food extruder.

| Base Material | 1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JISSKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy2)Ni-based alloy/Deloroalloy 3)Co-based alloy4)NiCo-based alloy 5)Tungsten carbide/Wolframcarbide |

| Double-alloylevel | Level A - containing Tungsten of40% Level B - containing tungsten of 25% Level C - containing tungsten of15% |

| Surface Treatment | Heat Treatment High FrequencyTreatment Nitriding treatment(120Hours): Depth of Nitrided Layer: 0.5-0.8mm Hardness of Nitrided Layer: 900-1020Hv(HRC56°-65°) HardChrome Plating treatment: Thickness of Hard Chrome Plating Layer:0.05-0.10mm Hardness ofHard Chrome Plating Layer: ≥950HV Nickel alloyplating.treatment: Bimetallic barrel / Cylinder: Centrifugal Casting(Inlay Alloy) BimetallicScrew: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55°-72° Spraying corrosion wear-resisting dual metallayers |

3 . Comparsion of the output (LDPE)

Pressure is generated if resin passes over the barrier, forcing any air in the melted resin back to the feed side and effectively preventing the intrusion of air bubbles on the sub flight side. This is highly effective with resins that generate bubbles such as PS, PA, PET and EVOH.

4 . Parallel twin screw and barrel application

1)PP

2)PE

3)PVC

4)WPC

5)SHEET/PIPE/PROFILE/ FOAM BOARD

6)CRANULAR TWIN SCREWS EXTRUDERS

5 . As per customer's demand,we can also supply below:

PVC/PE Film Blowing Screw;

Blow Molding Screw;

PS/PE/PP/ABS Sheet Extrusion Screw;

PE Aluminum Plate;

PPR Pipe Screw;

EVA Extrusion Screw;

HDPE High efficiency Screw;

PET Straps Screw;

XPS/EPE Foamed Screw;

Granulation Screw,Vented single screw etc.