BLOOM(suzhou) Materials Co.,Ltd |

|

Verified Suppliers

|

|

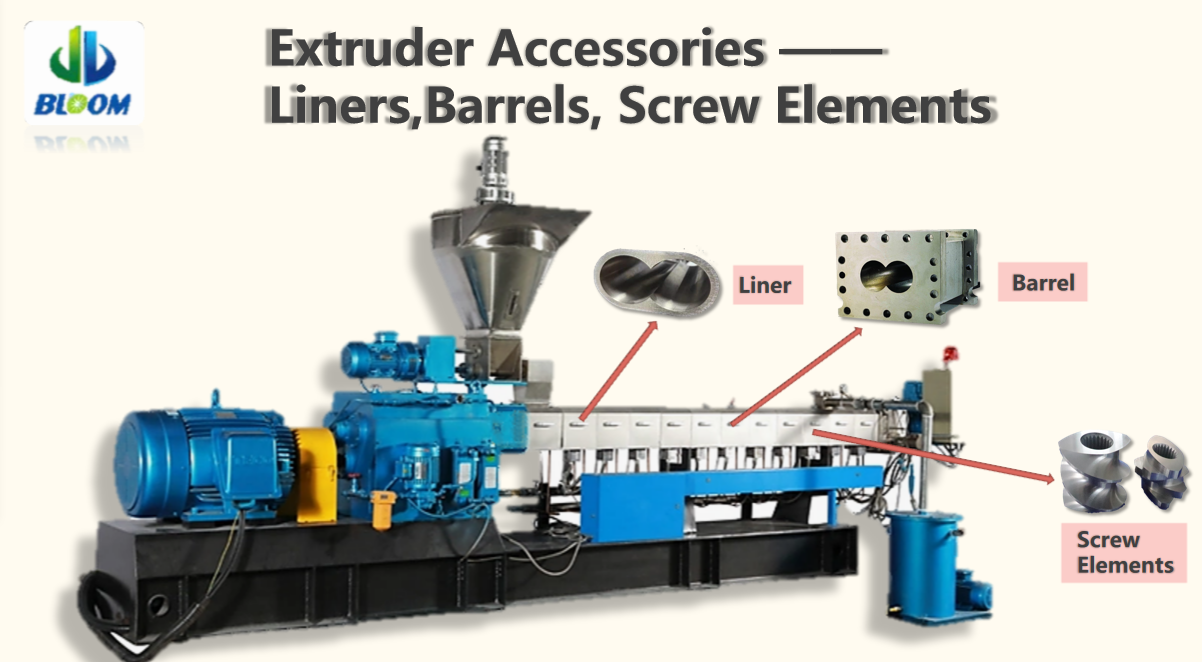

High Plastic Recycling Extruder Replacement Spare Parts Double Screw Extruder

1 . Factory introduction

We are a professional manufacturer of nickel base alloy, Hastelloy alloy, tungsten carbide alloy, cobalt base alloy and H.I.P liner sleeve.

We have provided super wear-resistant high corrosion resistance bushing for many domestic and foreign parallel twin-screw extruder customers and modification enterprises, and can be developed according to customer needs, combined with the actual conditions of high quality non-standard products, Oze product performance is excellent, stable quality, reasonable price, timely delivery, perfect after-sales.

Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element are used in the plastic extrusion industry, specifically in twin screw extruders. Twin screw extruders use two screws rotating in the same direction to mix, melt, and transport plastic materials through the extruder barrel.

The Extruder Barrel Screw Element is responsible for compressing, melting, and homogenizing the plastic material as it moves through the extruder. The corrosion-resistant material of the barrel and screw elements can withstand the high temperatures and corrosive chemicals used in the extrusion process, ensuring they remain durable and long-lasting even under harsh conditions.

These spare parts are designed to replace worn out or damaged barrel and screw elements in twin screw extruders, allowing the machine to continue operating at optimal efficiency. They can also be used to upgrade older equipment with new, more advanced components, improving performance and increasing productivity.

Overall, the use of Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element can contribute to the production of high-quality plastic products, while reducing downtime, maintenance costs, and the need for frequent replacement of extruder parts.

Alloy sleeve with eight holes, integral sleeve. Super corrosion resistant, wear resistant alloy sleeve for special materials. The barrel produced by our company is mainly made of the following two materials: (1) Bimetal bushing +45# steel housing This kind of cylinder produced by our company is made of domestic alloy bushing. It is characterized by strong wear resistance. The advantage is easy to repair, so as to reduce the user's use cost. (2) 38CrMoAIA nitrided steel cylinder Mainly good corrosion resistance

2 . The usage of Extruder Screws and Barrels Converying Elements

Twin screw extruder screws and barrels conveying elements are critical components of a twin screw extruder that work together to convey, melt, mix, and shape raw materials into a final product. These parts are essential for achieving the desired processing result and performance of the extruder.

Here are some key uses of twin screw extruder screws and barrels conveying elements:

Conveying: Feed screws and conveying elements are used to transport raw materials along the length of the extruder barrel towards the die or downstream equipment.

Melting: Melting is achieved by using kneading blocks, mixing elements, and distributive mixing elements. These elements facilitate the melting process by applying high shear forces, heat, and pressure to the material.

Mixing: Mixing elements are designed to create dispersive and distributive mixing of different materials and additives in the extruder. They can deliver a homogeneous and uniform mixture of materials, ensuring consistent quality and performance of the end product.

Shaping: Shaping elements, such as compression sleeves, restrictors, and dies, are used to control the flow and pressure of the melted material. The shaping elements ensure that the extruded product has the desired shape, size, and texture.

3 . The advantages

The use of Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element offers several advantages in the plastic extrusion process, including:

a . Improved durability: The extruder barrel and screw elements are exposed to high temperatures, abrasive materials, and corrosive chemicals during the extrusion process. Using corrosion-resistant materials for these parts can help prolong their lifespan and reduce their need for maintenance or replacement.

b . Enhanced performance: By using corrosion-resistant materials, the extruder can operate at higher temperatures without risk of damage or degradation. This can lead to improved melt quality, higher throughput rates, and better product consistency.

c . Cost savings: By reducing the frequency of part replacement or repair, using corrosion-resistant spare parts can help reduce production downtime and minimize costs associated with maintenance or replacement of worn-out parts.

d . Compatibility with a wide range of materials: A corrision resistant extruder barrel and screw element can be used with various types of plastic materials, including those that contain corrosive additives or are highly abrasive.

Overall, the use of Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element can contribute to higher efficiency, reduced downtime, lower maintenance costs, and improved product quality in the plastic extrusion process.

4 . Applicatons

Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element are used in the plastic extrusion industry, specifically in twin screw extruders. Twin screw extruders use two screws rotating in the same direction to mix, melt, and transport plastic materials through the extruder barrel.

The Extruder Barrel Screw Element is responsible for compressing, melting, and homogenizing the plastic material as it moves through the extruder. The corrosion-resistant material of the barrel and screw elements can withstand the high temperatures and corrosive chemicals used in the extrusion process, ensuring they remain durable and long-lasting even under harsh conditions.

These spare parts are designed to replace worn out or damaged barrel and screw elements in twin screw extruders, allowing the machine to continue operating at optimal efficiency. They can also be used to upgrade older equipment with new, more advanced components, improving performance and increasing productivity.

Overall, the use of Twin Screw Extruder Spare Parts with Corrosion Resistance Extruder Barrel Screw Element can contribute to the production of high-quality plastic products, while reducing downtime, maintenance costs, and the need for frequent replacement of extruder parts.

5 . Our QC Control

Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

6 . Our detection

Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

7 . Our Advantage

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry:

BLOOM(suzhou) Materials Co.,Ltd

Contact Person: Ms. Miranda

Tel: 0086-15250395817

Email: sales1@ttxalloy.com

Fax: 86-512-89598069