BLOOM(suzhou) Materials Co.,Ltd |

|

Verified Suppliers

|

|

38crmoaia Material Nitrided And Bimetallic For PVC Sheet And PVC Plate Parallel Twin Screw Barrel

1 . Factory introduction

Our factcory is a professional manufacturer of nickel-based alloys, Hastelloy alloys, tungsten carbide alloys, cobalt-based alloys and H.I.P inner bushings.

We have provided super wear-resistant and high corrosion-resistant

bushings for many domestic and foreign parallel twin-screw extruder

customers and modification companies, and can develop high-quality

non-standard products according to customer needs and in

combination with actual working conditions. Ouzi products Excellent

performance, stable quality, reasonable price, prompt delivery and

perfect after-sales service.

At present, our factory's workshop area exceeds 3,000 square

meters, and another 3,000 square meters is in the planning and

design, covering the complete production process of material

research and development, main parts production and testing. The

company has 6 technicians, more than 40 employees, and many

production and testing equipment imported from Taiwan and Germany.

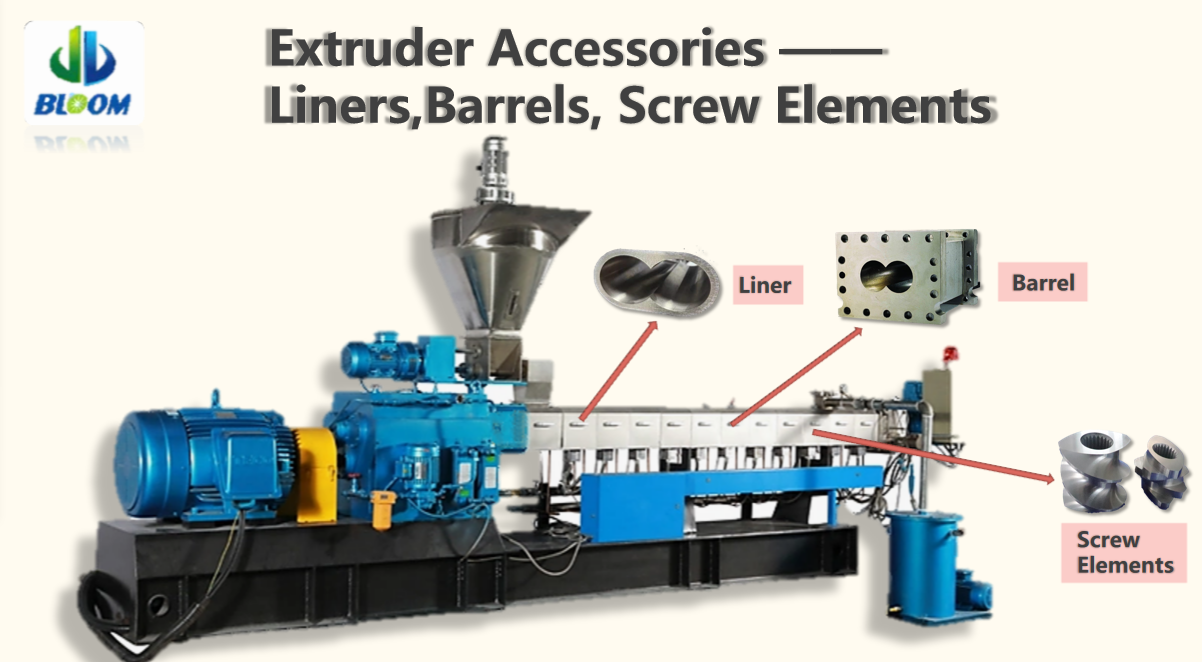

Twin-screw extruder screw elements, also known as screw segments or screw modules, are the individual components that make up the screw of a twin-screw extruder. These elements are designed to rotate within the barrel and work together to convey, mix, and melt the plastic material being processed. Each screw element has a specific function, such as conveying, mixing, or kneading, and can be customized to meet the specific processing requirements of different materials.

The screw barrel is the cylindrical housing that contains the screw elements and provides the necessary pressure and temperature for processing the plastic material. The screw barrel and elements work together to create the required shear forces and mixing action needed to properly process the material.

2 . 38CrMoAl Nitriding Material

38CrMoAlA steel is the most widely used nitrided steel. After

nitriding, the surface hardness can reach 1100~1200HV, and it has

high thermal stability. Its hardenability in oil can reach 50mm.

38CrMoAlA steel is used to manufacture nitrided parts with high

wear resistance, high fatigue strength and precise dimensions after

processing, such as screws and sleeves of injection molding

machines, boring bars of boring machines, worms, spindles of

grinders and automatic lathes, and cylinder sleeves , gears, valve

stems and imitations of steam turbines with operating temperatures

below 450°C.

A . Principle of nitriding heat treatment

Nitriding heat treatment is to infiltrate nitrogen atoms into the

surface of the material at high temperature to form a nitride

layer, thereby improving the hardness, wear resistance and

corrosion resistance of the material. In 38CrMoAl steel, nitriding

treatment can significantly improve its surface hardness and wear

resistance, and prolong the service life of the material.

B . Steps of nitriding heat treatment

a . Pretreatment: Pretreatment of 38CrMoAl steel, including removal

of surface oxides, oil stains and other pollutants, to ensure the

effect of nitriding treatment.

b . Nitriding: Put the pretreated steel in a nitriding furnace,

heat it to an appropriate temperature, and pass in

ammonia-containing gas to make nitrogen atoms penetrate into the

surface of the steel.

c . Quenching: After nitriding, the steel is quenched to allow

rapid cooling to form a high-hardness nitrided layer.

d . Temperature tempering: Temperature tempering is performed on

the quenched steel to reduce internal stress and improve toughness

and strength.

C . Effect of nitriding heat treatment

Nitriding heat treatment can significantly improve the surface

hardness of 38CrMoAl steel, usually up to 1000-1200HV. At the same

time, the nitride layer has high wear resistance and corrosion

resistance, which can effectively prolong the service life of the

material. In addition, nitriding can improve the high temperature

performance and fatigue life of the material.

D . Technology advantages

38CrMoAl nitriding process has the following advantages:

(1) Improve hardness: The nitrided layer formed on the surface of

nitrided 38CrMoAl steel has a higher hardness, which can

significantly improve the hardness and strength of the material and

increase the service life of the material.

(2) Improve wear resistance: The nitrided layer has good wear

resistance and friction properties, which can reduce the wear and

friction coefficient of the material surface and extend the service

life of the material.

(3) Improve surface quality: Nitriding treatment can improve the

finish and flatness of the surface of 38CrMoAl steel, and improve

the surface quality and aesthetics of the material.

(4) Improve corrosion resistance: The nitrided layer has good

corrosion resistance and can effectively prevent corrosion and

oxidation on the surface of 38CrMoAl steel.

The 38CrMoAl nitriding process is a commonly used surface treatment process that improves the hardness and wear resistance of the material by forming a layer of nitrogen-rich compounds on the surface of the metal material.

Chemical composition of 38CrMoAlA steel

| C | 0.35-0.43% |

| Si | 0.20-0.45% |

| Mn | 0.30-0.60% |

| P | ≤0.035% |

| S | ≤0.035% |

| Cr | 1.35-1.65% |

| Mo | 0.15-0.25% |

| AI | 0.70-1.10% |

3 . The advantages

The use of 38CrMoAIA material, whether nitrided or in a bimetallic configuration, in parallel twin screw barrels for PVC sheet and PVC plate extrusion offers several advantages:

Wear Resistance: The 38CrMoAIA material, when nitrided or used in a bimetallic configuration, provides excellent wear resistance. PVC processing involves abrasive materials and high temperatures, which can lead to wear and reduce the lifespan of the screw barrel. The use of 38CrMoAIA helps to mitigate wear, ensuring a longer service life and reducing the need for frequent replacements.

Corrosion Resistance: PVC processing often involves the use of additives and plasticizers that can be corrosive to metal surfaces. The 38CrMoAIA material, when nitrided or used in a bimetallic configuration, enhances the corrosion resistance of the screw barrel, protecting it from degradation due to chemical exposure.

Improved Mixing and Dispersion: The parallel twin screw configuration is well-suited for PVC extrusion processes as it provides excellent mixing and dispersion capabilities. When combined with the advantages of 38CrMoAIA material, the screw barrel can effectively distribute additives, fillers, and other components uniformly throughout the PVC melt, ensuring consistent quality in the extruded sheet or plate.

Thermal Stability: PVC extrusion involves high processing temperatures, and the material used for the screw barrel must exhibit good thermal stability to withstand these conditions. The 38CrMoAIA material, either nitrided or in a bimetallic configuration, offers excellent heat resistance, maintaining its mechanical properties and shape even at elevated temperatures.

Precise Control and Product Quality: The design and surface properties of the screw barrel, combined with the use of 38CrMoAIA material, contribute to improved material flow and melt homogeneity. This allows for precise control over the extrusion process, ensuring consistent product quality, dimensional accuracy, and surface finish of the PVC sheet or plate.

Mechanical performance parameters:

Tensile strength (σb) | ≥980 MPa |

| Yield strength (σs) | ≥835 MPa |

| Elongation (δ) | ≥14% |

| Impact toughness (AKV) | ≥71J |

| Hardness (HB) | ≤229HB |

5 . Our QC Control

Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

6 . Our detection

Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

7 . Our Advantage

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry:

BLOOM(suzhou) Materials Co.,Ltd

Contact Person: Ms. Miranda

Tel: 0086-15250395817

Email: sales1@ttxalloy.com

Fax: 86-512-89598069