Qingdao Florescence Marine Supply Co., LTD. |

|

Verified Suppliers

|

|

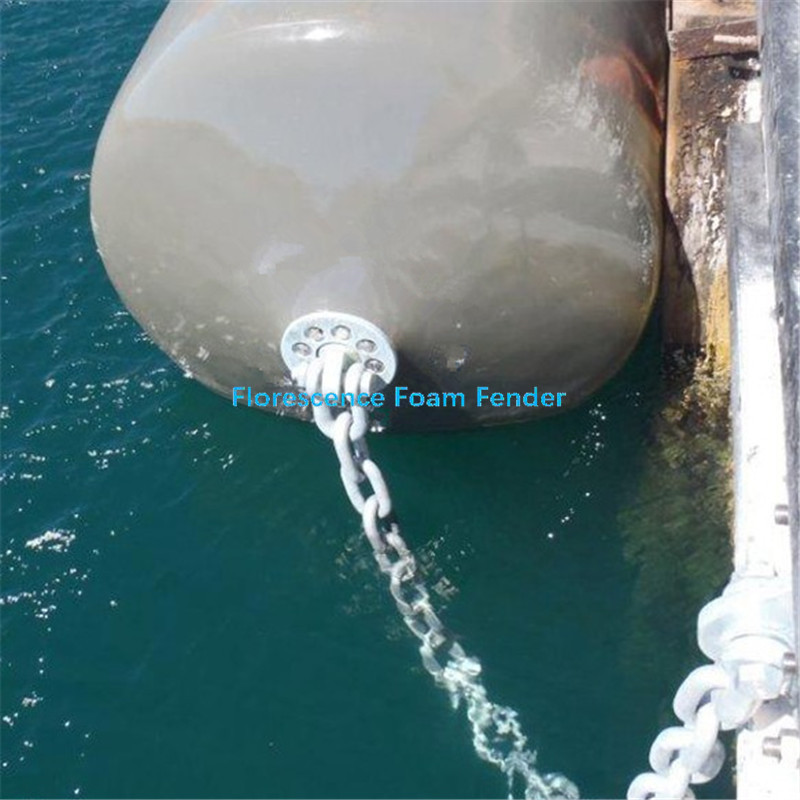

Qingdao Florescence foam fenders share a construction technology centred on a closed cell polyethylene foam core and an outer skin of reinforced polyurethane elastomer. The closed cell foam structure makes punctures a thing of the past. Every cell is separate and so water can't migrate into the foam. Even after many years of active service, the foam core can be returned to the factory, re-skinned and made ready for a new lease of life. No matter how badly abused, foam fenders will not burst or explode. Damage is rare, but if the worst should happen our foam fenders will still function until repairs are possible.

Structure of foam fender

The EVA foam fenders are constructed of three parts each providing

an important function in the construction and lifespan of the

fender. The three parts are (1) The closed cell polyurethane foam.

(2) Outer nylon cord fabrics. (3) Polyurea spraying coat.

(1) Foam Core

The closed cell polyurethane foam core used inside offers un-sink

ability during operation.

(2) Outer Nylon Cord Fabrics

The outer nylon cord fabrics is specifically designed to seal

polyurethane foam inside ability during operation.

(3) Polyurea Spraying Coating

Polyurea coating is permanent spray on coatings that protect the

surface of fender body. It is more durable than rubber and flexible

in all weather conditions: no softening in heat or becoming brittle

in cold. Dent, scratch and chemical resistant.

Foam filled fender main applications:

· Yacht and Navy

· Container ships and Cruise ships

· Ferries

· Oil and gas tankers

· General cargo vessels

Specifications:

| Foam Fender Size(mm) | Reaction Force(KN) | Energy Absorption(KJ) | Weight(±3%)(KG) |

| 300x500 | 43 | 5 | 5 |

| 400x800 | 54 | 7 | 13 |

| 500x1000 | 89 | 32 | 26 |

| 700x1500 | 129 | 24 | 75 |

| 1000x1500 | 190 | 62 | 154 |

| 1000x2000 | 298 | 80 | 205 |

| 1200x2000 | 335 | 110 | 295 |

| 1350x2500 | 460 | 173 | 466 |

| 1500x3000 | 615 | 263 | 691 |

| 1700x3000 | 678 | 330 | 888 |

| 2000x3500 | 940 | 535 | 1433 |

| 2000x4000 | 1095 | 630 | 1638 |

| 2000x4500 | 1250 | 690 | 1843 |

| 2300x4000 | 1380 | 735 | 2166 |

| 2300x5500 | 1860 | 1133 | 2979 |

| 2500x4000 | 1455 | 980 | 2559 |

| 2500x5500 | 1960 | 1230 | 3519 |

| 3000x5000 | 2180 | 1755 | 4607 |

| 3000x6000 | 2455 | 1960 | 5528 |

| 3300x4500 | 1960 | 1760 | 5017 |

| 3300x6500 | 3075 | 2830 | 7247 |

| 3500x7000 | 3975 | 3162 | 8779 |

Features of foam fender

1.Reinforced elastomer skin

EVA foam filled fenders have a nylon filament reinforced

polyurethane skin which has excellent resistance to water,

oil, ice, strong sunlight and abrasive surface. It remains flexible

even at -40°C (-40°F) making it suitable for Tropical or Arctic

operations.

2.Energy absorbing

The EVA foam filled fender absorbs impact energy so colliding

vessels will not damage the buoy or themselves.

3.Unsinkable foam

Only closed-cell foams are used in EVA foam filled fenders. The

micro-bubble matrix of the foam means it does not absorb water even

if cut or damaged. This makes EVA foam filled fenders impossible to

sink.

4.Permanent colors

The poly urea skin is pigmented through its entire thickness, so

colors will not wear off and will never need repainting. A wide

choice of bright colors can help improve safety and identification.

Advantages of foam fender

1. Good float-ability makes the installation site not affected by

tidal range.

2. Non-pneumatic operation, free from scratch and fiction,seawater

corrosion resistance and high salt-alkalia tolerance, longer

service life up to 15 years without regular maintenance.

3. Higher safety factor, free from explosion risk.