PingYang DEM Auto Parts Factory |

|

Verified Suppliers

|

|

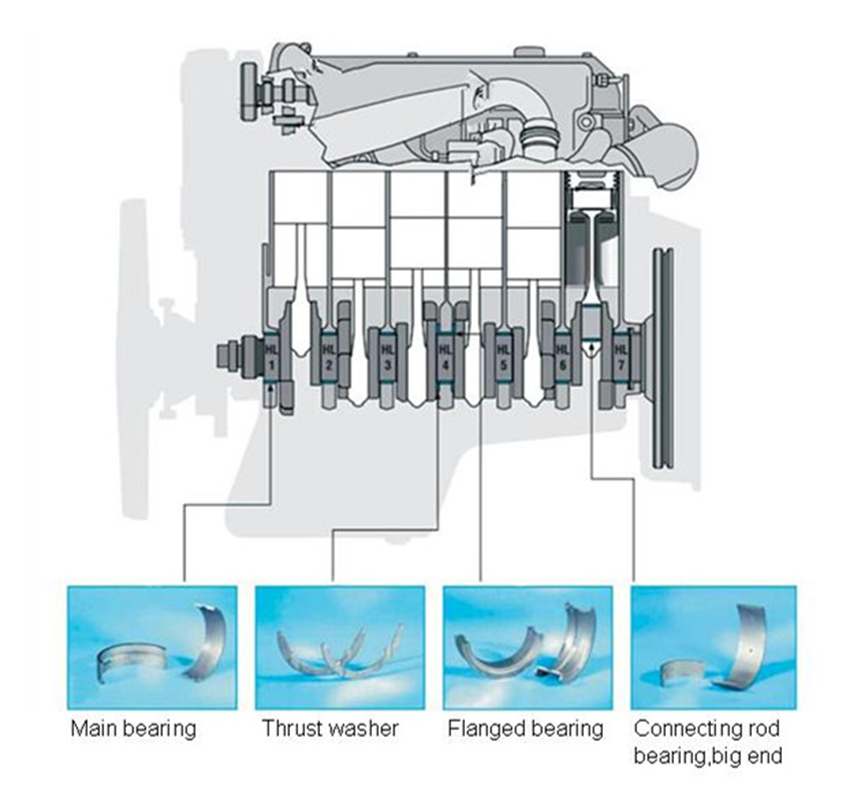

1Y/1Z - Engine Main Bearing For Audi 20-479/5A 1.9L Scratch-Resistant

Product Specification

| Model | 1Y/1Z - Engine Main Bearing For Audi 20-479/5A 1.9L Scratch-Resistant |

| Specification | STD 0.25 0.50 0.75 1.00 |

| Brand | TAJHO |

| Weight | 1.26kg/PC |

| Material | Aluminum-based |

| SIZE | Standard |

| Application | Machinery parts/Automobile Parts |

| Quality | ISO 9001:2008 ISO/TS16949 standard |

| Precision | 0.013mm |

| Service | OEM available |

Operation Method

Regular monitoring and maintenance of bearing shells is necessary. This can be achieved through the following steps:

Temperature monitoring: Use a suitable thermometer to regularly measure the working temperature of the bearing shells. Abnormal heating may indicate poor friction or insufficient lubrication.

Maintenance: According to the equipment manufacturer's maintenance manual, carry out regular maintenance work, such as lubricating oil replacement, inspection and tightening of fasteners, etc.

Temperature monitoring: Use a suitable thermometer to regularly measure the working temperature of the bearing shells. Abnormal heating may indicate poor friction or insufficient lubrication.

Maintenance: According to the equipment manufacturer's maintenance manual, carry out regular maintenance work, such as lubricating oil replacement, inspection and tightening of fasteners, etc

Observation: Regularly inspect the surface of the bearing pads for abnormal wear, cracks, or deformation.

Lubrication status monitoring: By analyzing grease or lubricating oil, determine the lubrication status of bearing shells, and promptly identify and solve problems.

Product Technology

After the production of the bearing pads is completed, they are assembled and installed. Install the bearing shells correctly into the equipment and make necessary connections and fastening. After assembly, verify whether the quality and performance of the bearing pads meet the requirements through corresponding testing and trial operation. If problems are found, adjustments and corrections need to be made.

As an indispensable and critical component of mechanical equipment, in the transmission system of railway vehicles, bearing pads are used to support and guide wheel axles, ensuring smooth train operation and reducing wear and tear on wheels and tracks.