Sichuan Vacorda Instruments Manufacturing Co., Ltd |

|

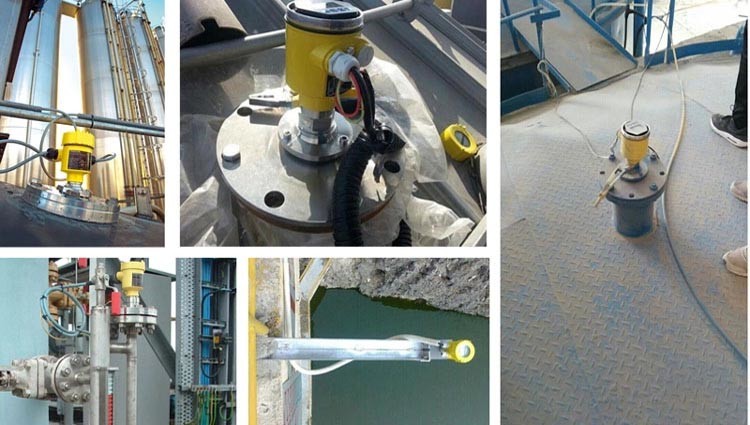

Explosion Proof Powder Granule Block 20m Radar Level Transmitter

Product Description

Radar liquid level sensor technology transmits a high frequency electromagnetic wave pulse typically in the microwave spectrum, and receives the wave reflected off a liquid surface. The time taken for the microwave pulse to traverse the distance between the transmitting antenna and target surface, and back again to the receiving antenna is measured.

The distance (d) between the radar liquid level sensor and the liquid surface can be calculated by dividing the time taken (t) by two, and multiplying that by the speed of light (c), i.e. d = c ∙ t / 2. The liquid level in a tank (LT) can then be determined by subtracting distance (d) from the height of the radar level sensor (HT), i.e. LT = HT – d.

Unlike ultrasonic sensors, the performance of a radar level sensor is not easily affected by temperature changes, humidity or vapour between the sensor and the liquid surface. This is because changes in air density only have a very small effect on the speed of electromagnetic waves. Also radar liquid level sensors can work in a vacuum, high pressures and high temperatures without any noticeable difference on measured transit time, so it can be used in applications where it is not possible to use ultrasonic based sensors.

Features:

1. No media contact for vertically mounted type, so flexibility for

use on different corrosive media, thick fluids, slurries,

wastewater

2. High temperature fluid compatibility for vertically mounted

types, since no sensitive components make contact with the fluid

3. High accuracy due to high frequency pulse wave and precise

transit time time measurement

4. Sealed pressurised vessel will not affect performance

5. Longer range than ultrasonics

6. Not affected by surface changes such as air temperature, which

cause problems with ultrasonics

♦903

| Suitable for Medium | Solid material, Strong dust,easy to crystallize, condensation occasion |

| Measuring Range | 70m | |

| Frequency | 26GHz | |

| Accuracy | ±15mm | |

| Process Temperature | -40℃~130℃(Standard type) -40℃~250℃(High temperature type) | |

| Process pressure | -0.1~4.0 MPa (Flat flange) -0.1~0.3MPa (Universal flange) | |

| Signal output | 4~20mA /HART (2-wire / 4-wire) RS485/ Modbus | |

| Power Source | Two-wire (DC24V) Four-wire(DC24V/AC220V) | |

| Connection | Universal Flange | |

| Protection Grade | IP67 | |

| Explosion-proof Grade | Exia IIC T6 Ga/Exd IIC T6 Gb |

♦904

| Suitable for Medium | Solid material, Strong dust,easy to crystallize, condensation occasion |

| Measuring Range | 80m | |

| Frequency | 26GHz | |

| Accuracy | ±15mm | |

| Process Temperature | -40℃~130℃(Standard type) -40℃~250℃(High temperature type) | |

| Process pressure | -0.1~0.3MPa | |

| Signal output | 4~20mA /HART (2-wire / 4-wire) RS485/ Modbus | |

| Power Source | Two-wire (DC24V) Four-wire(DC24V/AC220V) | |

| Connection | Thread, Universal Flange | |

| Protection Grade | IP67 | |

| Explosion-proof Grade | Exia IIC T6 Ga/Exd IIC T6 Gb |

♦906

| Suitable for Medium | Hygienic liquid storage, Corrosive container |

| Measuring Range | 20m | |

| Frequency | 26GHz | |

| Accuracy | ±3mm | |

| Process Temperature | -40℃ ~ 130℃ | |

| Process pressure | -0.1~4.0MPa | |

| Signal output | 4~20mA /HART (2-wire / 4-wire) RS485/ Modbus | |

| Power Source | Two-wire (DC24V) Four-wire(DC24V/AC220V) | |

| Connection | Flange | |

| Protection Grade | IP67 | |

| Explosion-proof Grade | Exia IIC T6 Ga/Exd IIC T6 Gb |

The sound wave is a mechanical wave with a density of 40; gas, liquid and solid 41; propagation depends on the influence of the medium, temperature and pressure on the measurement. Need temperature compensation. Temperature and pressure measurement are generally not applicable. First of all, the ultrasonic level gauge has a temperature limit. Generally speaking, the temperature of the probe cannot exceed 80 degrees, and the propagation speed of sound waves is greatly affected by temperature. Secondly, the ultrasonic level gauge is greatly affected by the pressure, generally within 0.3MPa, because the ultrasonic wave is emitted by the vibration of the piezoelectric material. When the pressure is too high, the sound part will be affected. Third, when the fog or dust in the measurement environment is large, the measurement effect is not good. The radar level gauge emits high-frequency pulses and propagates along the cable. When the pulse is in contact with the material surface, it is reflected by the receiver inside the instrument and the distance signal is converted into a material level signal. The electromagnetic wave is used as the detection signal, which is reflected to the interface as the dielectric constant changes. Electromagnetic waves can propagate in vacuum without being affected by changes in temperature and pressure. Therefore, it can be used in a high temperature and high pressure environment. The measurement of very low dielectric constant media is not applicable. The radar tube uses electromagnetic waves and is not affected by the degree of vacuum. It has a wide range of applications in terms of medium temperature and pressure. The emergence of high-frequency radar tubes makes the application range of radar tubes wider. Therefore, the radar tube is an

ideal choice for level measurement.

1.How to choose radar level measurement range

Due to the large blind area for measuring solid-state radars, the appropriate range of each radar is generally selected as follows (except for special media):

| model | Antenna size | Powder | Granules | Block |

| HKD905 | 121mm horn | 8-15m | 8-20m | 8-20m |

| 96mm horn | 3-12m | 3-15m | 3-15m | |

| 76mm horn | 3-8m | 3-10m | 3-10m | |

| The 76mm horn antenna has a weak signal. It is best to start with the 96mm horn antenna. | ||||

The measurement of solid-state lightning reaches, and the stronger the transmitting power (signal), the larger the corresponding upper blind zone. Therefore, when the range is small, the candidate high-frequency solid-state radar must verify the good range to avoid the pursuit of a large signal and a large blind zone. Impact measurement

2.Purge interface, the thread specification of solid-state radar purge interface is 1 / 8NPT, 8mm diameter fast purge connector on the interface

High-frequency radar level gauge parameters

| temperature: | Solid standard type: -40 ~ 130 ℃ High temperature type: -40 ~ 240 ℃ "; |

| application: | Measurement of powder, granules, blocks and other solids; |

| output signal: | RS485 output signal with single selection |

| Explosion proof: | Single-cavity intrinsically safe explosion-proof type: Exia IIC T6 Ga, when using on-site in explosion-proof occasions, it is required to install a safety barrier in the control room;Double-chamber flameproof type: Exd IIC T6, no need for central control and no safety barrier when used in explosion-proof occasions. When on-site power is 220V, only dual-chamber radar can be selected. |