Dongguan Hilbo Magnesium Alloy Material Co.,Ltd |

|

Verified Suppliers

|

|

Low Density , Good Specific Performance Magnesium Alloy Rod AZ31

AZ61

Magnesium alloys are the lightest structural metallic materials,

which makes them ideal within the aerospace industry. Magnesium

alloys have about ¼ the density of steels which also aids to

improving energy efficiency often seen in today’s automobile

manufacturing. Along with strength and ductility, Magnesium alloys

have excellent corrosion resistance.

Magnesium alloys, the lightest metal structure material for engineering applications, have taken a great interest in the automotive, aerospace, weapons, electronic and other fields, because of their low density, high specific strength and stiffness, good damping characteristics, as well as excellent castability. Especially in the field of automobile industry, magnesium alloys have replaced the steel, cast iron and even aluminum alloys (Magnesium is the lightest of all structural metals, aluminum being 1.5 times heavier and steel being 4 times heavier), because they can reduce the weight of vehicles, so that significantly contribute to fuel economy and reducing CO2 emissions.

Our main products and capacities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width:

3000mm; Max. Length: 6000mm

2. Magnesium alloy slab: Max. Size: 400 x 1000 x 2500mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm;

Max. Length: 2000mm

4. Magnesium cast bar: Min. Diameter 90mm; Max. Diameter: 600mm;

Max. Length: 6000mm

5. Magnesium extrusions:

Round tube: Max. OD 600mmx thickness 125mm Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm Rectangular: 700 x 200mm

6. Magnesium alloy machined part according to customer’s design

7. Magnesium anode as per customer’s design

Magnesium Alloy functions

1. High mechanical stability

2. High damping capacity

3. Low internal stresses and distortions

4. Good heat conductivity

5. Good machining properties

What is round bar magnesium used for?

Round Bar Magnesium Magnesium is the third-most-commonly-used

structural metal, following iron and aluminum. The main

applications of magnesium are, in order: component of aluminum

alloys, in die-casting (alloyed with zinc), to remove sulfur in the

production of iron and steel, and the production of titanium in the

Kroll process.

| Hilbo magnesium alloy material Co., Ltd. | ||||||||||||||

| Quality Inspection Report | ||||||||||||||

| NO:JB/MS03-151-1236 | ||||||||||||||

| Model | Specifications | Process | Furnace No. | Chemical Composition (%) | Low power test | |||||||||

| Al | Zn | Mn | Fe | Si | Cu | Ni | Mg | Low power | Surface quality | Size | ||||

| Ø80*1000 | Extrussion | 9850 | 8.5 | 0.60 | 0.3 | 0.005 | 0.1 | 0.05 | 0.005 | Balance | OK | OK | OK | |

| AZ80A H112 | ||||||||||||||

| Magnesium alloy bar | ||||||||||||||

| Tensile strength Rm /Mpa | Yield strength 0.2% Mpa | Elongation at break % | ||||||||||||

| 295 | 190 | 5 | ||||||||||||

| Conclusion :Passed inspection | ||||||||||||||

Feature:

Low density, good specific performance, good shock absorption performance, good electrical and thermal conductivity, good process performance, poor corrosion resistance, easy to oxidize and burn, and poor heat resistance. Its processing and corrosion and mechanical properties have many characteristics: fast heat dissipation, light weight, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recycling; in addition, there are high Features of thermal and electrical conductivity, non-magnetic, good shielding and non-toxic.

Performance test data:

| No. | Model | Test condition | Dissolution rate mg/(cm2*h)) | Strength of extension(MPa) | Yield strength(MPa) | Elongation (%) | Hardness (HB) |

| 1 | HB006 | 93℃/3%KCl | 50-70 | ≥370 | ≥260 | ≥2.5 | ≥90 |

| 2 | HB006A | 93℃/3%KCl | 50-70 | ≥310 | ≥220 | ≥6.0 | ≥75 |

| 3 | HB008 | 93℃/3%KCl | 40-60 | ≥400 | ≥300 | ≥4.0 | ≥100 |

| 4 | HB008B | 93℃/3%KCl | 40-60 | ≥370 | ≥270 | ≥5 | ≥100 |

| 5 | HB008C | 93℃/3%KCl | 40-60 | ≥310 | ≥220 | ≥15 | ≥85 |

| 6 | HB012 | 93℃/3%KCl | 40-60 | ≥400 | ≥300 | ≥3.0 | ≥100 |

| 7 | HB011 | 93℃/3%KCl | 15-35 | ≥420 | ≥300 | ≥3.0 | ≥100 |

| 8 | HB016 | 93℃/3%KCl | 35-55 | ≥280 | ≥180 | ≥15 | ≥60 |

| 9 | HB017 | 93℃/3%KCl | 40-50 | ≥200 | ≥140 | ≥17 | ≥55 |

| 10 | HB018K | 50℃/0.84KCl | 50-70 | ≥240 | ≥170 | ≥12 | ≥55 |

| 11 | HB018 | 50℃/0.84KCl | 30-50 | ≥230 | ≥170 | ≥12 | ≥55 |

| 12 | HB010 | 93℃/3%KCl | 15-35 | ≥190 | ≥120 | ≥30 | ≥45 |

| 13 | HB022 | 43℃/0.05%KCl | 50-60 | ≥300 | ≥200 | ≥5.0 | ≥75 |

| 14 | HB023 | 43℃/0.05%KCl | 20-40 | ≥280 | ≥200 | ≥7.5 | ≥65 |

| 15 | HB024 | 43℃/0.05%KCl | 50-70 | ≥260 | ≥220 | ≥5 | ≥60 |

| 16 | HB013A | 43℃/0.05%KCl | 80-100 | ≥260 | ≥230 | ≥3.5 | ≥75 |

| 17 | HB025 | 50℃/0.84%KCl | 90-110 | ≥275 | ≥200 | ≥12 | ≥65 |

| 18 | HB026 | 93℃/3%KCl | 20-40 | ≥450 | ≥350 | ≥3.0 | ≥110 |

| 19 | HB808 | 50℃/0.84%KCl | 50-70 | ≥370 | ≥260 | ≥3.0 | ≥100 |

| 20 | HB019 | 50℃/0.84KCl | 45-65 | ≥230 | ≥180 | ≥12.0 | ≥55 |

| 21 | HB055 | 93℃/3%KCl | 130-150 | ≥220 | ≥160 | ≥12.0 | ≥55 |

| 22 | HB035 | 93℃/3%KCl | 50-100 | ≥100 | ≥60 | ≥42.0 | ≥35 |

| 23 | HBMM6 | 50℃/0.84%KCl | 70-100 | ≥260 | ≥230 | ≥10.0 | ≥60 |

| 24 | HBMM7 | 50℃/0.84%KCl | 90-120 | ≥270 | ≥240 | ≥9.0 | ≥65 |

| 25 | HBMM8 | 93℃/3%KCl | 100-150 | ≥280 | ≥250 | ≥5.0 | ≥65 |

Advantage of Hilbo Company:

Full range of product types, Ensure production capacity

We ave advanced die-casting, extrusion, forging, rolling, casting processing production line and precision testing equipment. Can produce a variety of types of magnesium alloy and magnesium alloy products, and developed a high-strength magnesium alloy extruded sheet. Through the purification of ordinary magnesium, magnesium can be raised up to 99.99% of high purity.

Cost advantage

Magnesium alloy casting production can customized as your

requirement. the technical process is great, extrusion production

required for a variety of bar, no need to purchase from abroad,

extrusion molding products is easy molding, low energy consumption,

saving production costs.

Workshop:

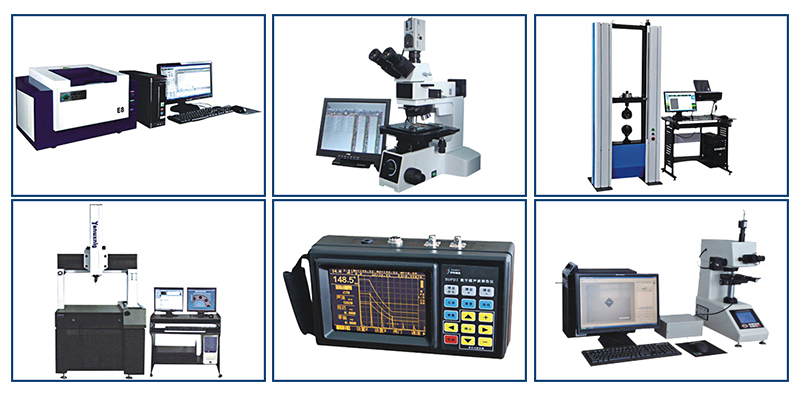

Testing Equipment

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

Certificate:

We have attained ISO9001 and ISO14001 certificates, Standardize and improve the enterprise quality management system.