Dongguan Hilbo Magnesium Alloy Material Co.,Ltd |

|

Verified Suppliers

|

|

Az31b Az61a Az91D Magnesium Alloy Rod / Bar For Auto Parts Or 3C Products

Details:

Product name | Magnesium Alloy bar |

Material grade | AZ31B/ZK60A/AZ91D/AZ61A/AZ80A/WE43 |

Lead Time | 3 to 25 working days |

Standard | ASTM B265,ASME SB265,AMS4911,ASTM F136,ASTM F67 |

Shape | bar, rod |

Package | Wooden pallet or according to customer's request |

Dimensions | Thickness:0.3mm-200mm |

Width:customized Max.width 3000mm | |

Length:Customized |

Magnesium Alloy Chemical Composition:

Model | Chemical Component(%): | ||||||

Type | Mg | Al | Zn | Mn | Si | Fe | Cu |

AZ31B | residual | 2.5-3.5 | 0.60-1.4 | 0.20-1.0 | ≤0.08 | ≤0.003 | ≤0.001 |

AZ61A | residual | 5.8-7.2 | 0.40-1.5 | 0.15-0.50 | ≤0.10 | ≤0.005 | ≤0.005 |

AZ80A | residual | 7.8-9.2 | 0.20-0.80 | 0.12-0.50 | ≤0.10 | ≤0.005 | ≤0.005 |

AZ91D | residual | 8.5-9.5 | 0.45-0.90 | 0.17-0.40 | ≤0.08 | ≤0.004 | ≤0.001 |

Magnesium Alloy | Mechanical Property | Application | ||

ASTM | tensile strength(N/MM2) | Yield strength(N/mm) | Elongation | -- |

AZ31B | 230~290 | 170~210 | 10~24 | Standard extrusion alloy |

AZ61A | 270~390 | 190~240 | 9~15 | High strength extrusion alloy |

AZ80A | 330~360 | 230~250 | 8~10 | High strength extrusion alloy |

Density: 1.8

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa

Poissons ratio: 0.35

Melting range: 566 - 632°C.

Performance test data:

| No. | Model | Test condition | Dissolution rate mg/(cm2*h)) | Strength of extension(MPa) | Yield strength(MPa) | Elongation (%) | Hardness (HB) |

| 1 | HB006 | 93℃/3%KCl | 50-70 | ≥370 | ≥260 | ≥2.5 | ≥90 |

| 2 | HB006A | 93℃/3%KCl | 50-70 | ≥310 | ≥220 | ≥6.0 | ≥75 |

| 3 | HB008 | 93℃/3%KCl | 40-60 | ≥400 | ≥300 | ≥4.0 | ≥100 |

| 4 | HB008B | 93℃/3%KCl | 40-60 | ≥370 | ≥270 | ≥5 | ≥100 |

| 5 | HB008C | 93℃/3%KCl | 40-60 | ≥310 | ≥220 | ≥15 | ≥85 |

| 6 | HB012 | 93℃/3%KCl | 40-60 | ≥400 | ≥300 | ≥3.0 | ≥100 |

| 7 | HB011 | 93℃/3%KCl | 15-35 | ≥420 | ≥300 | ≥3.0 | ≥100 |

| 8 | HB016 | 93℃/3%KCl | 35-55 | ≥280 | ≥180 | ≥15 | ≥60 |

| 9 | HB017 | 93℃/3%KCl | 40-50 | ≥200 | ≥140 | ≥17 | ≥55 |

| 10 | HB018K | 50℃/0.84KCl | 50-70 | ≥240 | ≥170 | ≥12 | ≥55 |

| 11 | HB018 | 50℃/0.84KCl | 30-50 | ≥230 | ≥170 | ≥12 | ≥55 |

| 12 | HB010 | 93℃/3%KCl | 15-35 | ≥190 | ≥120 | ≥30 | ≥45 |

| 13 | HB022 | 43℃/0.05%KCl | 50-60 | ≥300 | ≥200 | ≥5.0 | ≥75 |

| 14 | HB023 | 43℃/0.05%KCl | 20-40 | ≥280 | ≥200 | ≥7.5 | ≥65 |

| 15 | HB024 | 43℃/0.05%KCl | 50-70 | ≥260 | ≥220 | ≥5 | ≥60 |

| 16 | HB013A | 43℃/0.05%KCl | 80-100 | ≥260 | ≥230 | ≥3.5 | ≥75 |

| 17 | HB025 | 50℃/0.84%KCl | 90-110 | ≥275 | ≥200 | ≥12 | ≥65 |

| 18 | HB026 | 93℃/3%KCl | 20-40 | ≥450 | ≥350 | ≥3.0 | ≥110 |

| 19 | HB808 | 50℃/0.84%KCl | 50-70 | ≥370 | ≥260 | ≥3.0 | ≥100 |

| 20 | HB019 | 50℃/0.84KCl | 45-65 | ≥230 | ≥180 | ≥12.0 | ≥55 |

| 21 | HB055 | 93℃/3%KCl | 130-150 | ≥220 | ≥160 | ≥12.0 | ≥55 |

| 22 | HB035 | 93℃/3%KCl | 50-100 | ≥100 | ≥60 | ≥42.0 | ≥35 |

| 23 | HBMM6 | 50℃/0.84%KCl | 70-100 | ≥260 | ≥230 | ≥10.0 | ≥60 |

| 24 | HBMM7 | 50℃/0.84%KCl | 90-120 | ≥270 | ≥240 | ≥9.0 | ≥65 |

| 25 | HBMM8 | 93℃/3%KCl | 100-150 | ≥280 | ≥250 | ≥5.0 | ≥65 |

Advantage of Hilbo Company:

Full range of product types, Ensure production capacity

We ave advanced die-casting, extrusion, forging, rolling, casting processing production line and precision testing equipment. Can produce a variety of types of magnesium alloy and magnesium alloy products, and developed a high-strength magnesium alloy extruded sheet. Through the purification of ordinary magnesium, magnesium can be raised up to 99.99% of high purity.

1. Various size of magnesium material in stock

2. Direct factory

3. Strict inspection and fast delivery (MTC will be attached)

4. Short delivery and size can be customzied 5.Quite professional

with great experience

Cost advantage

Magnesium alloy casting production can customized as your

requirement. the technical process is great, extrusion production

required for a variety of bar, no need to purchase from abroad,

extrusion molding products is easy molding, low energy consumption,

saving production costs.

Workshop:

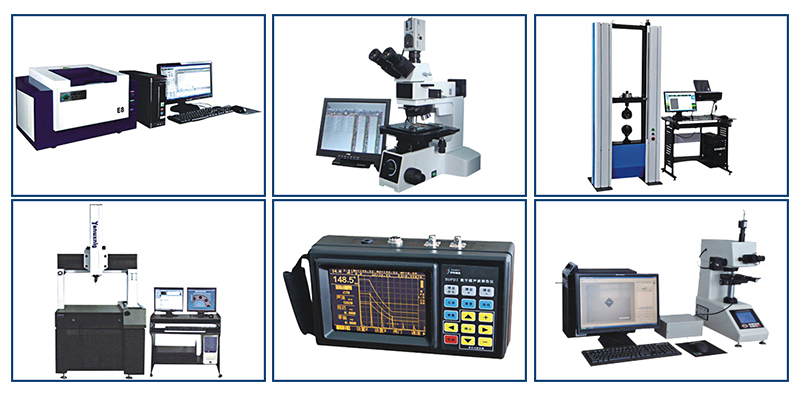

Testing Equipment

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

Certificate:

We have attained ISO9001 and ISO14001 certificates, Standardize and improve the enterprise quality management system.

FAQ: