JYC technology Co.,Ltd |

|

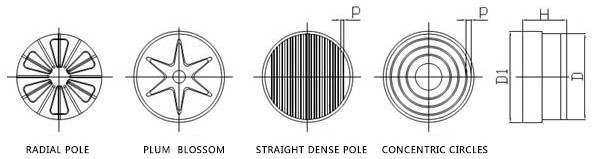

X21 circular electro magnetic chuck

500MM X21 Circular X21 circular electro magnetic chuck

Product Introduction

The working principle of the permanent magnet fixture is to use the characteristics of different permanent magnet materials, through the electronic control system on the internal magnetic circuit distribution control and conversion, so that the system internal magnetic field to achieve their own balance, or degaussing state, or release to the fixture Surface, that is, magnetic state.

Product Parameters

| Spec Sheet: | ||||||||

| Product name | Model | Technical parameters | Table type | Net weight (KG) | ||||

| D×H (MM) | Voltage (V) | Current (A) | Power (W) | Pole pitch (MM) | ||||

| Circular ECMC | X21-250 | Φ265×110 | 110 | 0.73 | 86 | 4+11 | Concentric circles | 40 |

| X21-320 | Φ325×105 | 110 | 0.8 | 86 | 4+11 | 65 | ||

| X21-400 | Φ420×115 | 110 | 1.34 | 148 | 4+11 | 110 | ||

| X21-500 | Φ510×107 | 110 | 1.1 | 123 | 4+11 | 160 | ||

| X21-550 | Φ550×110 | 110 | 2 | 220 | 4+12 | 200 | ||

| X21-600 | Φ600×118 | 110 | 3.4 | 377 | 4+12 | 250 | ||

| X21-780 | Φ780×228 | 110 | 4.2 | 462 | 4+12 | 700 | ||

| X21-800 | Φ820×180 | 110 | 3.5 | 385 | 4+12 | 705 | ||

| X21-1000CY | Φ1040×181 | 110 | 4.5 | 496 | 4+12 | 1000 | ||

| Spec Sheet: | ||||||||

| Circular ECMC | X21-1250CY | Φ1290×210 | 100 | 13.9 | 1376 | 4+13 | Concentric circles | 1800 |

| X21-1400CY | Φ1408×238 | 110 | 10 | 1100 | 4+13 | 2300 | ||

| X21-1600CY | Φ1680×210 | 110 | 14.6 | 1600 | 4+13 | 3000 | ||

| X21-510Z | Φ510×107 | 110 | 1.1 | 123 | 4+1 | Straight dense pole | 145 | |

| X21-630Z | Φ640×135 | 110 | 3 | 330 | 4+1 | 305 | ||

| X21-780Z | Φ780×200 | 110 | 5.1 | 561 | 4+1 | 705 | ||

| X21-400M | Φ400×105 | 110 | 0.85 | 92 | Plum blossom | 100 | ||

| X21-500M | Φ560×128 | 110 | 1.96 | 216 | 170 | |||

| X21-630M | Φ677×138 | 110 | 3 | 330 | 300 | |||

| Radial ECMC | Pole amount | Note | ||||||

| X21-600F | Φ650×120 | 110 | 3 | 330 | 12 | Radial Pole | 300 | |

| X21-700F | Φ700×150 | 110 | 4 | 440 | 12 | 450 | ||

| X21-800F | Φ800×150 | 110 | 5 | 550 | 14 | 580 | ||

| X21-900F | Φ900×150 | 110 | 6 | 660 | 16 | 730 | ||

| X21-1000F | Φ1000×150 | 110 | 8 | 990 | 18 | 900 | ||

| X21-1300F | Φ1350×170 | 110 | 10 | 1000 | 24 | 1700 | ||

| X21-1600F | Φ1600×180 | 110 | 16 | 1760 | 24 | 2600 | ||

| X21-1800F | Φ1800×180 | 110 | 20 | 2200 | 36 | 3300 | ||

| X21-2500F | Φ2500×190 | 110 | 22 | 2450 | 40 | 6800 | ||

| Note: Other specifications can be customized ,please call for further information. | ||||||||

| Permanent Magnetic Chuck | Electromagnetic Magnetic Chuck | Electro Permanent Magnetic Chuck | |

| Magnetic Source | Ndfeb | Coil and Core | Ndfeb Anico |

| Magnetic Force Principle | Internal Magnetic Fields | Constant Current | Conversion by Electronic Control Device |

| Usage | Manual | Electric Control Device | Electric Control Device |

| Precision | About 0.02-0 05 (the Error Increased Bysizes) | About 0.01-0.02 | About 0 002-0.005 |

| Potential Risk | Prone to Security Incidents | Prone to Security Incidents | Absolute Safety |

| Magnetic Regulation | Unable to Adjust | Electric Control Device to Adjustsuction | Electric Control Device to Adjust Suction |

| Suction | Small | Medium | Large |

| Residual Magnetism | More Remanence, Demagnetiz Ation Devicerequired | Less Remanence, Demagnetizationdevice Required | Automatic Demagnetiz Ation Withoutdemagnetization Device |

| Thermal Deformation | No | Continuous Power On, Heat Generationand Thermal Deformation | No |

| Applicable Workpiece | Thin and Small Workpieces | Thin and Small, Medium Sizedworkpieces | All Kinds of Workpieces |

| Application | Mainly Used for Grinding Machine | Mainly Used for Grinding Machine | For Grinding/milling/lathe Manchine and Soon. |

| Accessories | No | Electric Control Device | Electric Control Device |

| Serive Life | 3-5 Years | 6-10 Years | 20 Years |

Application Scenario

Why Choose Us?

Safety, Magnetism Continue 30years Without Electric. Energy saving, Above 95%.

The Clamping Force Can Be As nigh As More Than 20 Kg/cm2.

High Efficiency, Improve The efficiency of More Than 60%.

Very Easy to Use, Fast, Durable, Maintenance Free.

Processing Technology

1. Cnc Flame Cutting

2. Gantry Milling

3. Cnc Processing Centor

6. Coils and Magnetic Steel Assembly

5. Deburring and Cleaning

4. Drilling Machine

7. Magnetic Steel Commissioning

8. Electrical with Stand Voltage Detection

9. Epoxy Potting

10. Suction and Pull-out Force Test

11. Surface Grinder Finish Machining

12. Surface Magnetic Remanence (inspection)

13. Finished Product Electrical with Stand Voltage Detection

14. Finished Product Appearance Inspection

15. Packing List Inspection

16. Finished Package

Company Profile

As a professional designer and manufacturer ofmagnetic products over 10 years, Wuxi Jiuyicheng Technology Company Limited is always providing customers appro-priate solutions to holding and lifting materialduring machining progressing.

The huge range of our magnetic products includeElectro magnetic

chuck(EMC) series, Permanentmagnetic chuck(PMC) series, Electro

permanentmagnetic chuck(EPMC) series, Electro magneticlifter

(EML),.Permanent magnetic lifter(PM-L),Electro permanent magnetic

lifter (EPML),Iron remover, Demagnetizer, etc.

Magnet is widely used in industries like metallurgy, machinery,

shipbuilding, electric power, mine, automobile manufacturing, rail

transportation and so on.

There is mainly 3 kinds of magnet, permanent magnet, electromagnet, permanent electromagnet. different magnet is suitable for different areas, and as a professional supplier of magnetic tools, JYC technology is is always providing customers appropriate solutions for our customers.

FAQ

Q: Are you manufactory or trade company.