Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

Custom Precision Sheet Metal Fabrication Parts | |

Quotation | According to your drawing(size, material, thickness, processing

content, and required technology, etc) |

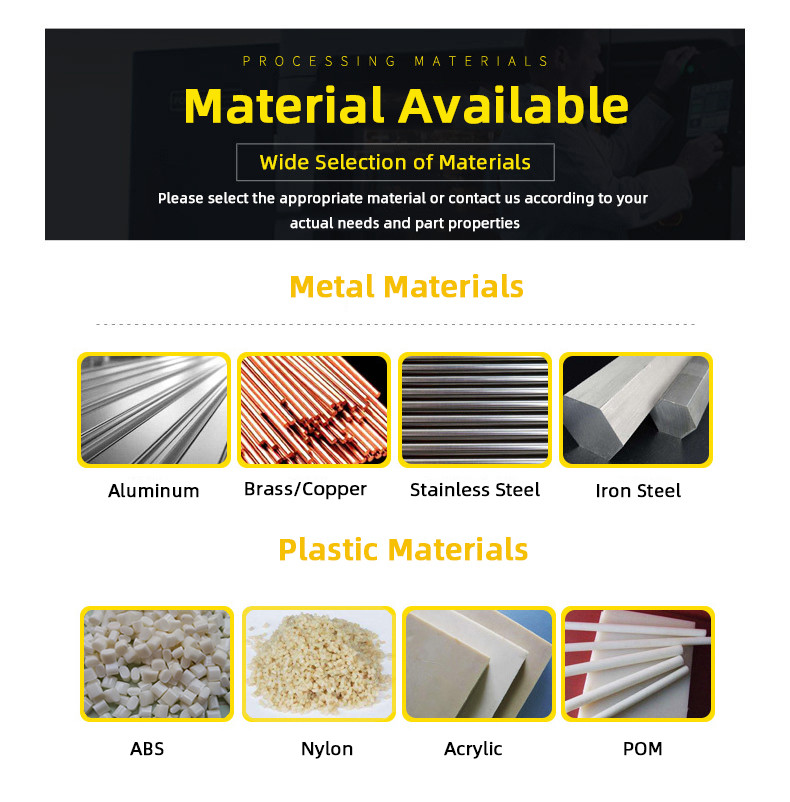

Material | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper,

etc. |

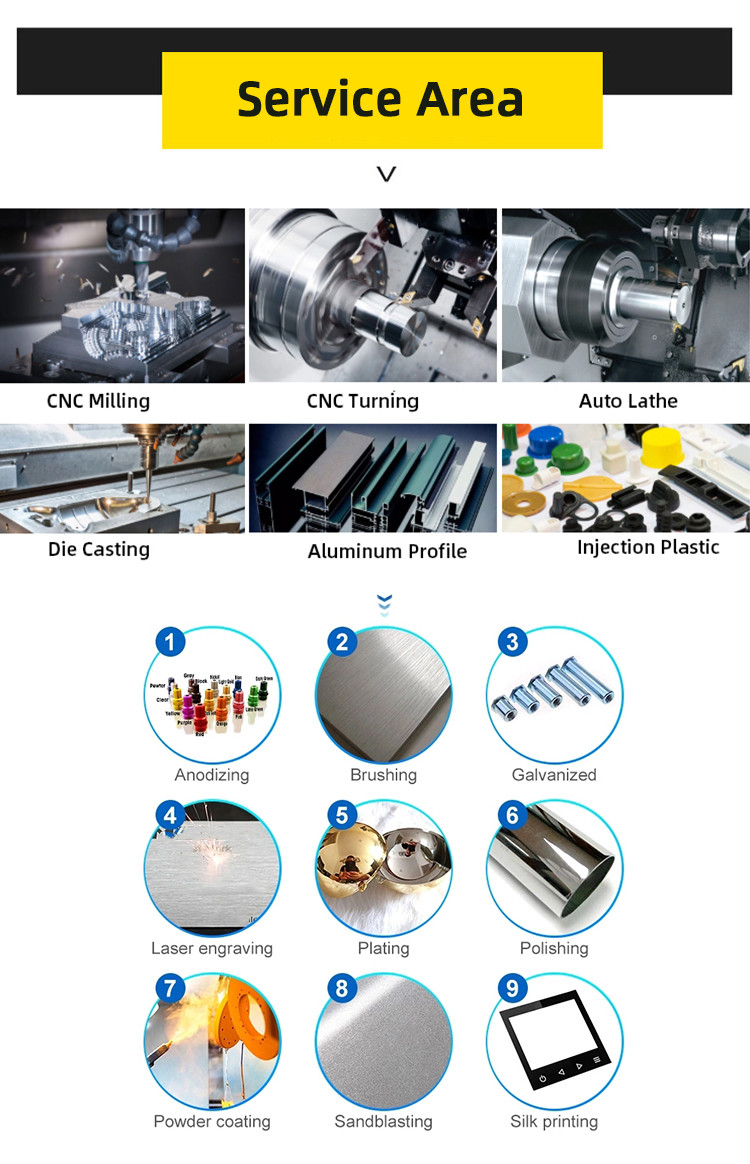

Processing | Laser Cutting, Precision Stamping, Bending, CNC Punching,

Threading, Riveting, Drilling, Welding etc |

Surface Treatment | Brushing, Polishing, Anodizing, Powder Coating, Plating, Silkscreen

printing, Sandblast, etc |

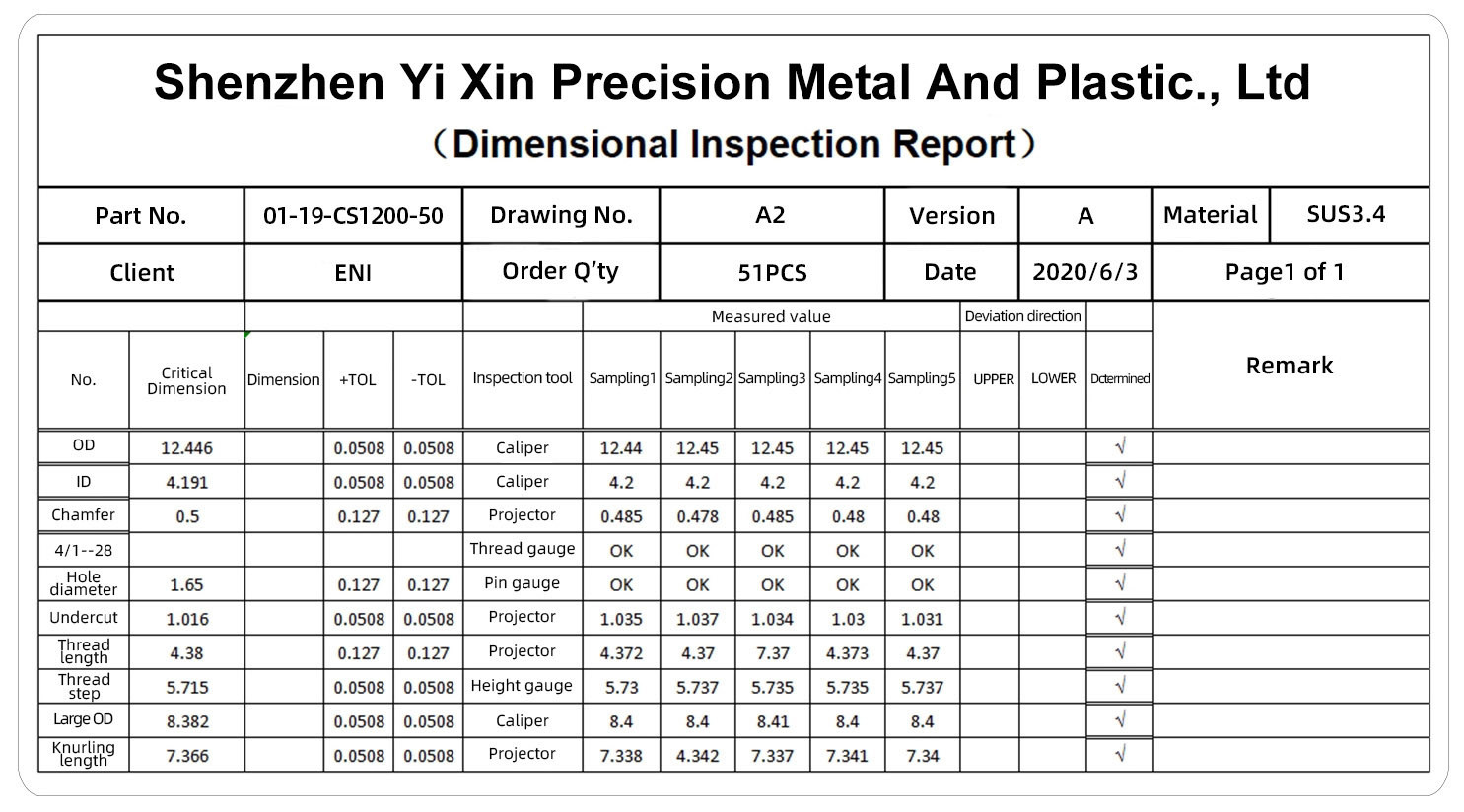

Tolerance | +/-0.2mm, 100% QC quality inspection before delivery, can provide

quality inspection form |

Logo | Silk print, Laser marking. |

Size | Accept custom size. |

Color | White, black, silver, red, grey, Pantone and RAL, etc |

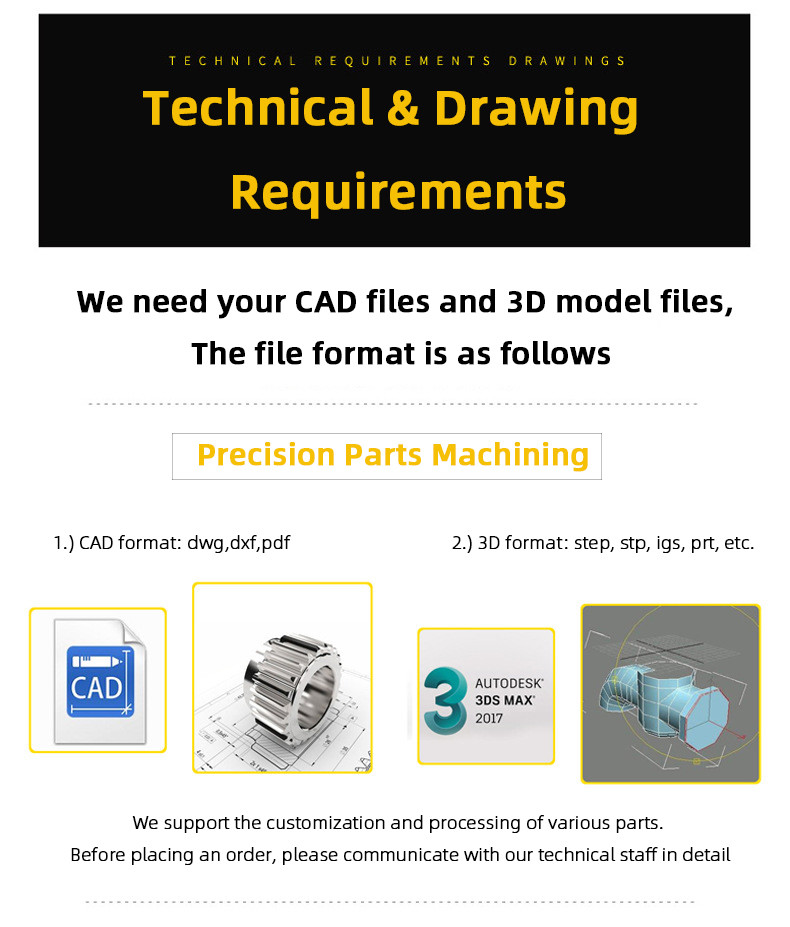

Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft. |

Sample lead time | No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

Pricing Term | EXW, FOB, CIF, etc |

Payment term | Sample: 100% payment before production Mass production: (50% in advance as deposit, balance before

delivery) |

Certificate | ISO9000:2015/SGS/TUV/RoHS |

Packing | By carton or as your request |

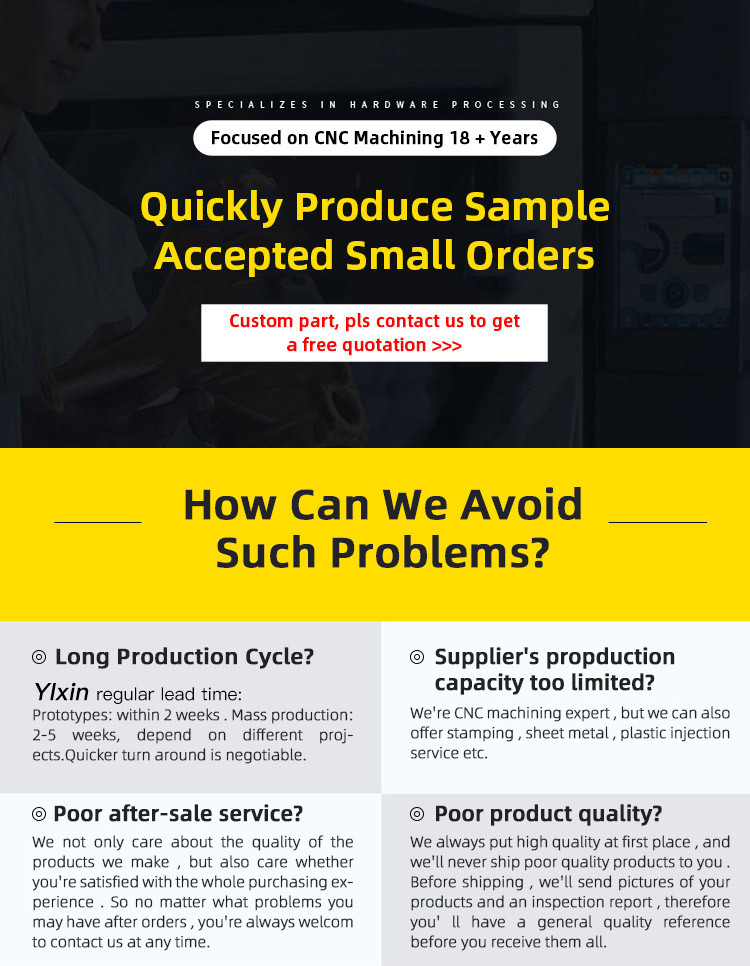

1. quotation

① Customers provide drawings (format: CAD, PDF, STP) or samples. The following drawing information is clear: processing quantity, materials, precision tolerance, surface treatment and special requirements. We can modify or design the drawings according to the customer's requirements.

② Quotation time (within 5 minutes at the fastest, 24 hours at the slowest, except in special circumstances). We will reply to the customer as soon as we receive the drawing or sample.

2. Price

Negotiate with customers and promise to do our best to offer lower prices. But price is not the only factor in our service. Quality, delivery, after-sales service attitude are equally important.

3. Quality

① Equipment support: We are an entity factory with complete equipment, including lathe, milling machine, grinding machine, drilling machine, wire cutting (fast and slow), CNC (turning and milling), engraving machine, etc.

② Quality inspector: there is a special person to do relevant inspection on the parts.

③ Service team: arrange professional leaders to follow up.

4. Delivery date

① Production time: Order followers follow up the whole process. If there is any change in delivery date, communicate and negotiate with the customer 2 days in advance;

② Logistics delivery: Due to the weight of mechanical products, delivery methods need to be negotiated by both sides, for relatively small products are generally sent mainly by express, for relatively large or heavy products sent to logistics or steam, but also hope that buyers understand, the specific consensus

5. After-sales

After the customer receives the product, if the product does not meet the requirements, we will first analyze where the problem lies. If it is our processing error, we will arrange to redo it or give a full refund as soon as possible. If the product is scrapped due to the buyer's wrong drawing, we will discuss it separately. Any problem can be solved satisfactorily through communication and negotiation until you are satisfied.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

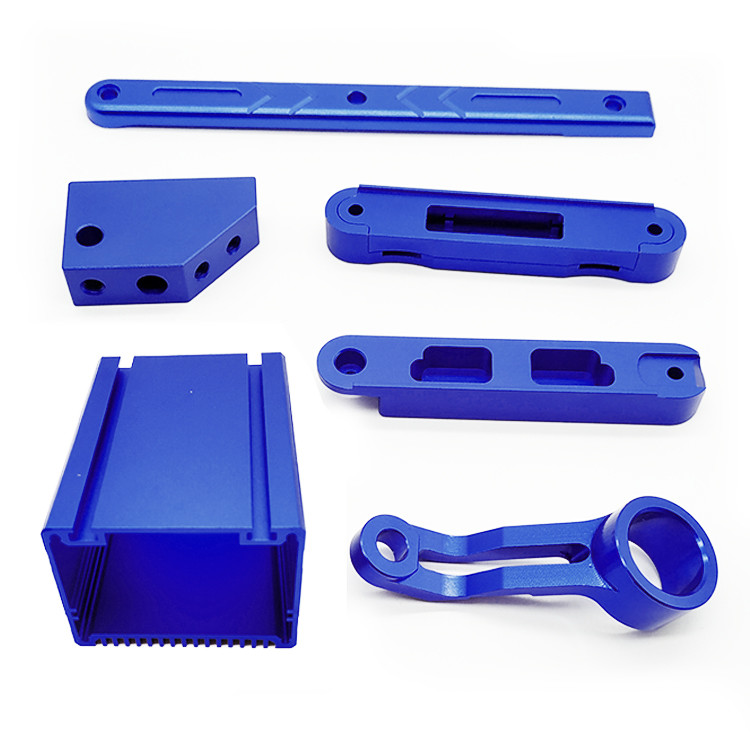

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.